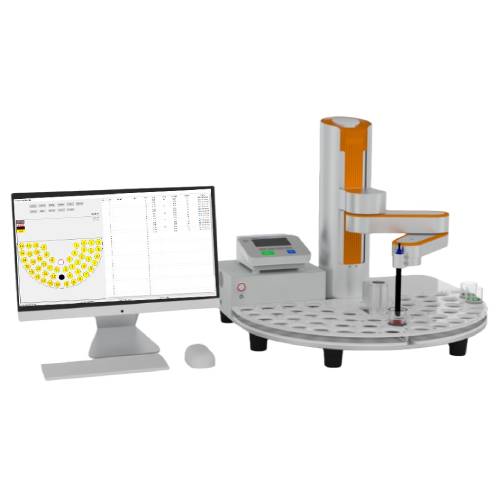

Automatic Liquid Dosing System for Textile Color Fastness

The Automatic Liquid Dosing System for Textile Color Fastness is designed for precise and automated dispensing of liquids for textile color fastness testing, including wash fastness, dry cleaning fastness, and shrinkage-resistant fastness tests. It is also suitable for evaluating the wash fastness performance of dyes. The system ensures accurate dosing, stable temperature control, and uniform liquid distribution.

Application

Automated liquid dispensing for textile wash fastness tests

Automated liquid dispensing for dry cleaning fastness tests

Liquid preparation for shrink-resistant textile color fastness tests

Dye wash fastness performance evaluation

Suitable for laboratories, textile manufacturers, and quality control departments

Standards

GB/T 3921.1 – 3921.5: Textiles — Color fastness tests to washing, Test 1–5

ISO 105-C10: Textiles — Color fastness to washing using soap or soap and soda

GB/T 5711: Textiles — Color fastness to dry cleaning

GB/T 12490: Textiles — Color fastness to domestic and commercial laundering

JIS L0860: Test method for color fastness to dry cleaning

JIS L0844: Color fastness to soap washing

AATCC 61: Accelerated test for home and commercial laundering color fastness

Technical Parameters

| Parameter | Specification |

|---|---|

| Control Interface | Color touch screen, user-friendly dialogue mode |

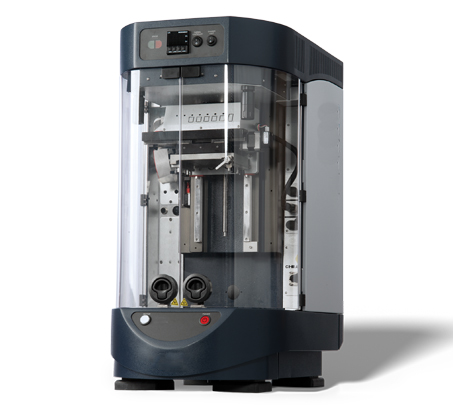

| Material | Stainless steel interior, durable and aesthetically pleasing |

| Dosing Method | Automatic calculation based on sample weight and liquor ratio, real-time weight monitoring of up to 24 samples |

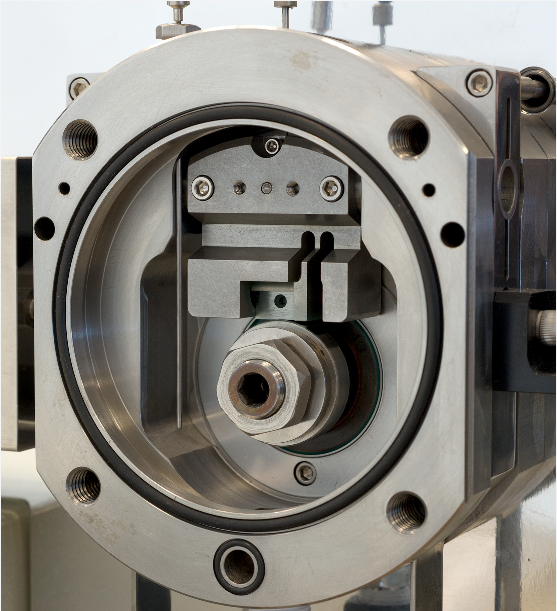

| Stirring | Built-in stirring device ensures uniform and stable liquid temperature |

| Temperature Control | PID algorithm, minimal fluctuation, prevents overshoot |

| Calibration | Built-in temperature calibration program |

| Safety Features | Water level sensor to prevent dry running |

Features

User-friendly interface: Color touch screen with intuitive human-machine interaction

Durable design: Full stainless steel interior for long-term use

Automatic dosing: Real-time weight measurement and calculation for precise liquid dispensing

Uniform temperature: Stirring system maintains consistent temperature throughout the bath

Stable temperature control: PID-controlled, minimizing overshoot and fluctuations

Self-calibration: Built-in program for easy temperature calibration

Safety protection: Water level sensor prevents dry heating and protects the equipment

Accessories

Stainless steel bath and mixing tank

Sample containers

Integrated balance for automatic weight measurement

Temperature sensors and PID controller

Software for liquid dispensing calculation and monitoring

Test Procedures

Sample Preparation: Place textile samples in the system’s sample holders.

Liquid Dispensing: The system automatically calculates the required liquid volume based on sample weight and pre-set bath ratio, then dispenses the liquid.

Temperature Control: The built-in stirring device and PID control maintain uniform and stable liquid temperature.

Monitoring: The system monitors liquid levels in real-time to prevent dry running.

Data Logging: Records sample weights, dispensed volumes, and liquid levels for traceability and quality control.

Maintenance Information

Regularly clean the stainless steel bath and sample holders

Check the water level sensor and stirrer function for proper operation

Perform periodic calibration of temperature sensors

Inspect software and balance system to ensure accurate dosing

Replace worn or damaged seals and gaskets as needed

FAQ

1. What is this product?

A fully automated system for liquid dispensing in textile color fastness tests.

2. What is this product used for?

To automate the addition of liquids for wash, dry cleaning, and shrink-resistant color fastness testing of textiles and for evaluating dye performance.

3. Why is this product important?

Ensures accurate, reproducible liquid dosing and temperature control, reducing manual errors and improving laboratory efficiency.

4. What industries is this product suitable for?

Textile laboratories, dye manufacturers, quality control departments, and textile R&D facilities.

5. What types of this product are available?

Automatic dosing systems with integrated balance, temperature control, and built-in stirring for single or batch sample testing.

Leave Message Get Price