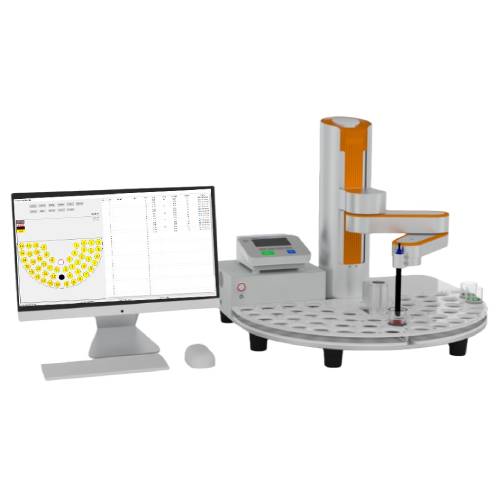

Universal Online Particle Size Analyzer

The Universal Online Particle Size Analyzer is an in-line particle size measurement system designed for real-time monitoring of particle size distribution in continuous powder production processes. It enables continuous detection of particle size on production lines, improving product quality consistency, reducing energy consumption, minimizing off-spec batches, and enhancing automation and process intelligence. This system is essential for modern continuous powder production quality control.

Application

Process control of chemical powder raw materials and intermediates

Online particle size monitoring of pharmaceutical APIs and excipients

Particle size classification control in mining and mineral processing

Online detection in building materials production (cement, mineral powders, fillers)

Quality control in food and additive powder production

Carbon materials, abrasives, and functional powder production lines

Standards

ISO 13320 – Particle size analysis by laser diffraction

GB/T 19077 – Particle size analysis, laser diffraction method

ASTM B822 – Laser diffraction measurement of metal powders

ASTM E1617 – Guidelines for laser diffraction particle size analysis

Parameters

| Parameter | Specification | Remarks |

|---|---|---|

| Measurement Range | 0.1 μm – 300 μm / 0.1 μm – 800 μm | Two selectable ranges |

| Measurement Mode | Continuous online real-time analysis | Data transmission frequency configurable |

| Sampling Method | Mechanical / Pneumatic / Venturi | Multiple options available |

| Return Method | Mechanical / Pneumatic / Auto-return | Supports automatic return to line |

| Channels | 38 | — |

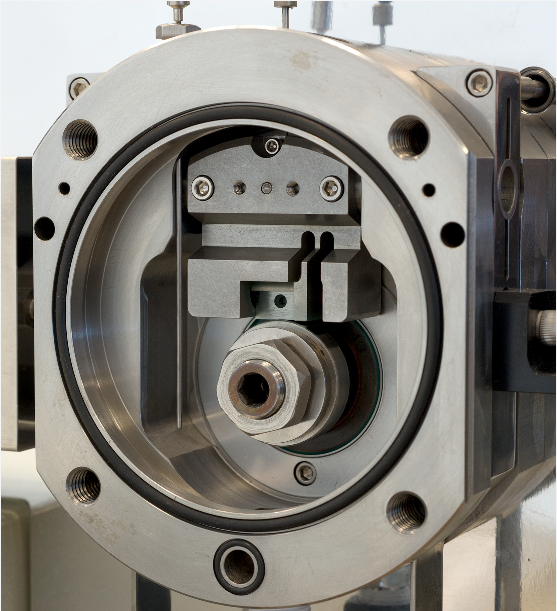

| Laser | He-Ne, 632 nm, 2 mW | — |

| Protection Rating | IP54 | — |

| Accuracy | <3% | — |

| Repeatability | <3% | — |

| Continuous Operation | 24 hours | Automatic alarm function |

| Operating Temperature | -15 °C to 45 °C | — |

| Operating Humidity | 0% to 60%, non-condensing | — |

| Machine Dimensions | 1.0 m × 0.6 m × 1.5 m | — |

| Machine Weight | Approx. 80 kg | Complete system |

| Cloud Monitoring | Optional | Supports data upload to cloud server |

Features

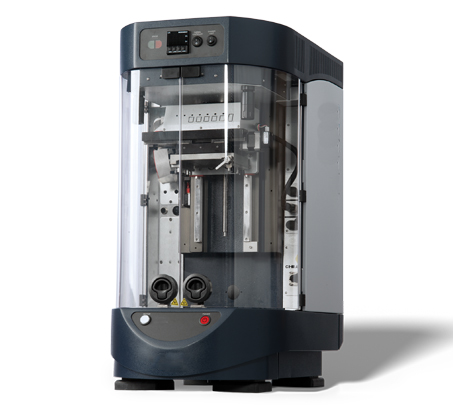

High versatility: Modular design allows flexible combination of sampling, measurement, and return modules to suit different industrial conditions.

Wide application range: Applicable to carbon, building materials, chemicals, abrasives, pharmaceuticals, and other industries.

High measurement accuracy: Automatic sampling combined with real-time analysis eliminates human operation errors; more precise than traditional off-line or sieve-based methods.

Real-time data: Provides immediate feedback on process conditions, enabling timely adjustments and reducing off-spec products.

Stable long-term operation: Resistant to vibration, dust, and electromagnetic interference; supports power-off protection, production stop protection, and automatic cleaning.

Automatic return design: Samples are automatically returned to the production line, preventing material loss.

Strong system integration: Standard data interfaces for connection with DCS or PLC systems for unattended operation.

Accessories

| Accessory / Option | Description |

|---|---|

| Mechanical Sampling Module | Automatic sample collection from production line |

| Pneumatic Sampling Module | Non-contact sampling with pressurized air |

| Venturi Tube Sampling Module | Suction-based sampling module |

| Automatic Sample Return Module | Returns tested material to production line |

| Cloud Monitoring & Data Management | Optional cloud-based data upload and monitoring |

| DCS / PLC Communication Interface | Standard interface for integration with industrial control systems |

Test Procedures

Install the sampling module, measurement module, and return module according to production line configuration.

Calibrate sensors and ensure proper installation of modules.

Set measurement parameters: sampling frequency, data acquisition rate, and return method.

Start online measurement and monitor particle size distribution in real time.

After testing, the sample is automatically returned to the production line.

Export or transmit measurement data to control systems for process optimization.

Maintenance Information

Periodically clean and inspect sampling modules, optical path, and measurement chamber.

Check and calibrate laser and sensors at regular intervals to ensure accuracy.

Inspect return module and conveyance pathways for blockages.

Ensure the system is free from dust and moisture during operation.

Perform software updates and backups regularly for reliable data storage.

FAQ

1. What is this product?

It is an online particle size analyzer that measures particle size distribution in powder production lines in real time.

2. What is this product used for?

It is used for continuous monitoring of particle size to control process quality, reduce off-spec products, and improve production automation.

3. Why is this product important?

It ensures product consistency, reduces waste, optimizes production efficiency, and enables real-time process control.

4. What industries is this product suitable for?

Applicable to chemical, pharmaceutical, mining, building materials, food, carbon materials, abrasives, and functional powder industries.

5. What types of this product are available?

Variants include mechanical, pneumatic, and Venturi sampling modules; return modules; and optional cloud monitoring systems.

Leave Message Get Price