Automated Clutch Friction Test Machine

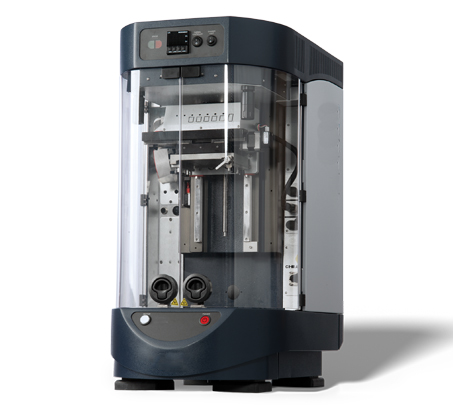

The Automated Clutch Friction Test Machine is a laboratory test system designed to evaluate friction, wear behavior, and thermal performance of wet clutch friction components under controlled load, speed, and lubrication conditions. The machine operates using a single original-manufactured friction pair, allowing detailed analysis of friction characteristics that cannot be obtained from full clutch pack or small-scale specimen testing.

The system supports precise speed control, closed-loop load application, temperature regulation, and automated data acquisition, making it suitable for standardized clutch friction research and comparative performance evaluation.

Application

The Automated Clutch Friction Test Machine is used for the following applications and components:

Wet clutch friction plate friction coefficient and torque characterization

Wear and durability evaluation of clutch friction materials

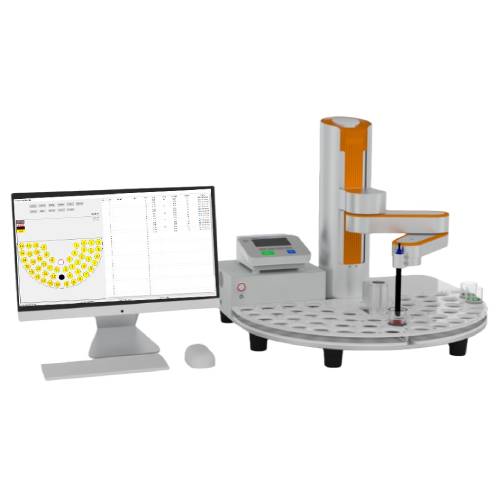

Engagement and disengagement behavior analysis under cyclic loading

Testing of small-scale friction components such as thrust washers

Friction performance assessment of limited-slip differential components

Evaluation of synchronizer and torque converter friction elements

Lubricant and friction material development and validation

Thermal behavior and heat dissipation studies of friction interfaces

Research, development, and quality control in automotive and transmission industries

Standards

GB/T 13986 — Determination of Friction Characteristics of Automotive Wet Clutches

JASO M349 — Test Method for Wet Clutch Performance

ISO 6312 — Automotive Clutch Friction Performance Testing

SAE J2491 — Clutch Friction and Wear Test Method

ASTM D3703 — Determination of Friction Properties of Friction Materials

Parameters

| Item | Technical Parameters |

|---|---|

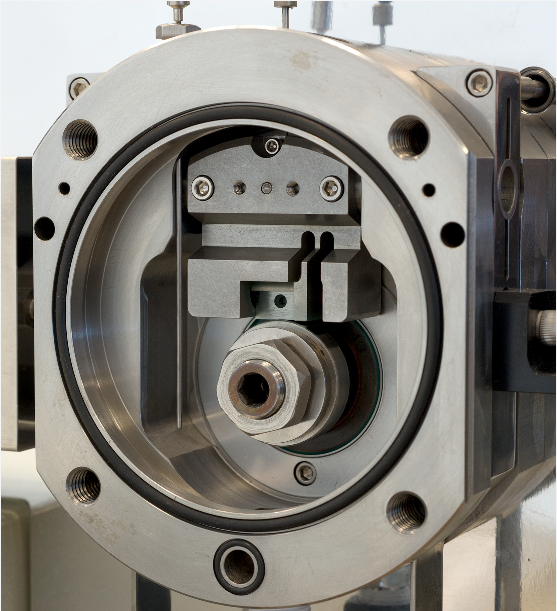

| Friction pair size | Mean friction radius 35–125 mm |

| Maximum specimen diameter | 286 mm |

| Small specimen friction radius | 15 mm |

| Speed control ratio | 100:1 |

| Drive motor | AC motor, 4 kW, encoder feedback |

| Load range (low load) | 50 – 1,000 N |

| Load range (high load) | 250 – 10,000 N |

| Load actuation | Pneumatic bellows, closed-loop control |

| Torque measurement | Strain gauge torque transducer |

| Maximum torque | 180 Nm |

| Torque arm radius | 187 mm |

| Heating method | Electrical resistance heating |

| Heating power | 3 kW |

| Temperature range | 40 – 200 °C |

| Temperature sensor | Type K thermocouple |

| Cooling method | Circulating heat transfer fluid |

| Cooling flow rate | Up to 4 L/min |

| Controlled parameters | Speed, load, temperature, test duration |

| Measured parameters | Speed, load, friction torque, temperature, friction coefficient, time |

| Power supply | 380/415 V, three phase, 50/60 Hz |

| Compressed air | 4 cfm @ 8 bar |

| Cooling water | 10 L/min (typical) |

| Machine dimensions | 600 × 800 × 1,000 mm |

| Machine weight | 400 kg |

Features

(1) Single friction pair test configuration enabling detailed friction characterization

(2) Wide speed control range with stable operation down to zero speed

(3) Closed-loop pneumatic load application with force feedback

(4) Modular clamping system accommodating different clutch plate diameters and spline types

(5) Integrated heating and cooling for controlled thermal test conditions

(6) Accurate friction torque measurement independent of load application

(7) Automated test sequencing and continuous data recording

(8) Safety protection including mechanical overload limitation and software alarms

Accessories

(1) Modular clutch plate clamping system for different diameters and spline geometries

(2) Pneumatic load application assembly with force transducer

(3) Temperature sensors for lubricant and specimen surface monitoring

(4) Heat transfer fluid circulation module for cooling

(5) Electrical resistance heating elements

(6) Safety guarding and mechanical overload protection components

(7) PC-based control and data acquisition system

Test Procedures

(1) Install the friction components using the appropriate modular clamps

(2) Fill the test bath with the specified volume of lubricant

(3) Set test parameters including speed profile, load level, temperature, and duration

(4) Activate heating or cooling to reach the target test temperature

(5) Apply load gradually using the pneumatic loading system

(6) Start the test sequence and record friction torque, speed, temperature, and load

(7) Monitor test conditions and stop the test if alarm thresholds are exceeded

(8) After completion, unload the specimen and perform wear inspection and data analysis

Maintenance Information

Regularly inspect pneumatic components, seals, and load actuators for leaks or wear.

Clean the test bath, clamps, and lubrication passages after each test series.

Verify calibration of torque, load, and temperature sensors at scheduled intervals.

Ensure electrical connections, safety guards, and emergency stop functions operate correctly.

Disconnect electrical, pneumatic, and fluid supplies before performing maintenance.

FAQ

(1) What is this product?

It is a laboratory test machine designed to measure friction torque, friction coefficient, wear behavior, and temperature response of wet clutch friction components.

(2) What is this product used for?

It is used for research, development, and quality control of clutch friction materials, lubricants, and related transmission components.

(3) Why is this product important?

It enables detailed friction analysis using real clutch components, providing data that cannot be obtained from full clutch pack tests or small-scale specimen methods.

(4) What industries is this product suitable for?

It is suitable for automotive manufacturing, transmission development, lubricant formulation, friction material research, and academic tribology laboratories.

(5) What types of this product are available?

The system supports multiple load ranges and modular fixtures to accommodate different clutch sizes and friction component configurations.

Leave Message Get Price