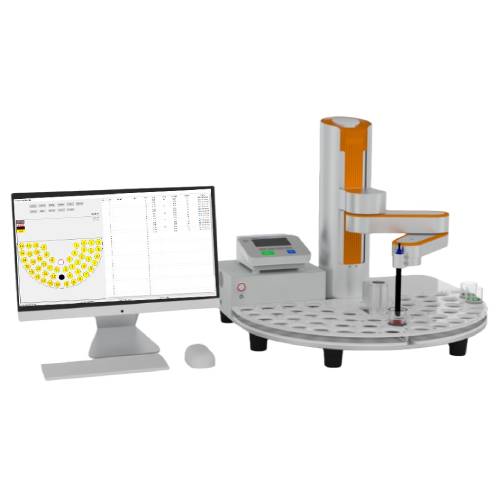

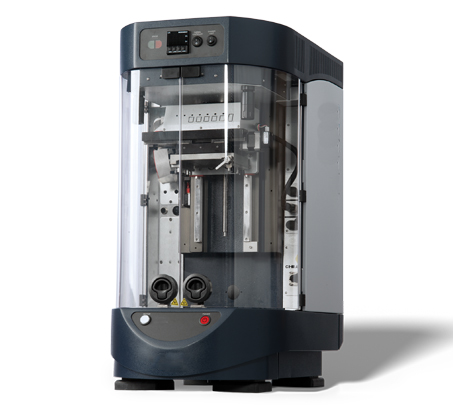

Intelligent Sample Cutting Machine

The Intelligent Sample Cutting Machine is a high-efficiency automated cutting device integrating automation and intelligence. It is widely applied in textiles, garments, footwear and leather, composite materials, and laboratory testing. The machine can accurately and quickly cut samples, significantly improving production efficiency and reducing material waste.

Application

Automated sample cutting in textile, apparel, and footwear industries

Cutting of composite materials for R&D or testing laboratories

Rapid and precise cutting for quality control and material testing

Reducing material waste in prototype or small-batch production

Enhancing efficiency in research, design, and production workflows

Standards

Not explicitly stated; supports standard design formats including PLT, DST, DXF, CAD for cutting files.

Compatible with industrial software for computer-aided cutting.

Parameters

| Parameter | Specification |

|---|---|

| Processing Area | 1000 × 1000 mm or 1600 × 1200 mm |

| Machine Type | Desktop or Floor-standing |

| Transmission | Servo motor + planetary straight-head reducer |

| Work Table | Vacuum adsorption platform (optional) |

| Effective Cutting Area | 1000 × 1000 mm or 1600 × 1200 mm |

| Speed Control | 0–100% manual and software control |

| Drive Type | Dual drive / High-speed DSP servo motor or single drive |

| Cutting Accuracy | ±0.1 mm (depending on material) |

| Cutting Speed | 0–2400 mm/s (depending on material) |

| Maximum Cutting Thickness | 4 cm |

| Control System | Zhongrui / Qiancheng / Ruida (Chinese-English LCD) |

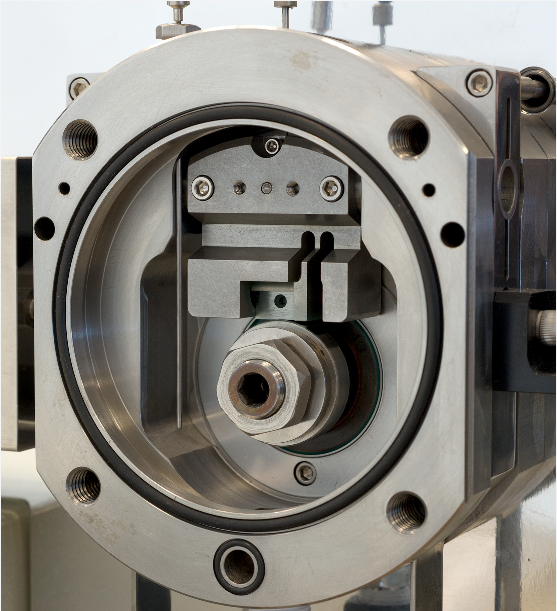

| Transmission System | Servo motor, linear guide rail, rack and pinion, ball screw |

| Working Environment | Temperature 0–40 °C; Humidity 5–95% (non-condensing) |

| Supported File Formats | PLT / DST / DXF / CAD |

| Control Method | Computer-aided design (CAD) control |

| Data Transmission | Industrial network port |

| X/Y Axis Motor | X: 750 W, Y: 400 W |

| Z/W Axis Motor | Z: 100 W, W: 100 W |

| Machine Dimensions | 1500 × 1400 mm or 2100 × 2000 mm |

| Power Supply | AC 220 V ±10%, 50/60 Hz |

| Total Power | 2 kW |

| Machine Weight | ~0.6 t or ~0.8 t |

Features

High precision and speed: Accurate cutting with ±0.1 mm tolerance and speeds up to 2400 mm/s.

Flexible processing area: Supports 1000 × 1000 mm or 1600 × 1200 mm for different materials.

Automated vacuum table: Optional vacuum adsorption for stable sample fixation.

Multiple drive and control options: Dual-drive high-speed DSP or single-drive servo motor, controlled via software.

Wide compatibility: Supports PLT, DST, DXF, CAD file formats for seamless CAD-based cutting.

User-friendly interface: LCD control system with Chinese-English display.

Robust industrial design: Linear guide rails, rack and pinion, and ball screw ensure smooth and precise cutting.

Safe and efficient operation: Desktop or floor-standing options, suitable for laboratory or production environments.

Accessories and Consumables

| Accessory / Consumable | Description |

|---|---|

| Main Unit | 1 set |

| Cutting Knife (Round) | 2 pcs |

| Computer | 1 set |

| Certificate of Conformity | 1 pc |

| User Manual | 1 set |

| Product Brochure | 1 set |

Test Procedures

Place the material on the vacuum adsorption work table (if equipped).

Load the CAD or compatible cutting file into the computer control system.

Set cutting parameters such as speed, path, and thickness according to material specifications.

Start the machine; the servo motor system performs precise cutting along the programmed path.

Monitor operation via the LCD interface.

After cutting, remove samples and inspect for accuracy and quality.

Maintain cleanliness of the cutting surface and blades to ensure long-term precision.

Maintenance Information

Regularly check and clean cutting knives to maintain sharpness and precision.

Inspect linear guide rails, rack and pinion, and ball screws for wear and lubrication.

Periodically calibrate cutting accuracy and speed.

Ensure vacuum table and work surface are free from dust and debris.

Maintain software updates and check electrical and motor systems for optimal operation.

FAQ

1. What is this product?

An automated intelligent cutting machine for samples and materials in textiles, composites, and laboratories.

2. What is this product used for?

Precision cutting of textile, garment, composite, and experimental samples.

3. Why is this product important?

Improves efficiency, reduces material waste, and ensures accurate, repeatable sample preparation.

4. What industries is this product suitable for?

Textile, garment, footwear, composite materials, R&D laboratories, and quality control departments.

5. What types of this product are available?

Desktop or floor-standing versions, with optional vacuum adsorption table and multiple processing area sizes (1000 × 1000 mm or 1600 × 1200 mm).

Leave Message Get Price