Block-on-Ring Test Machine

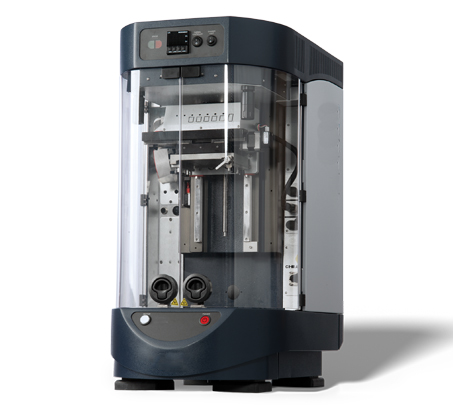

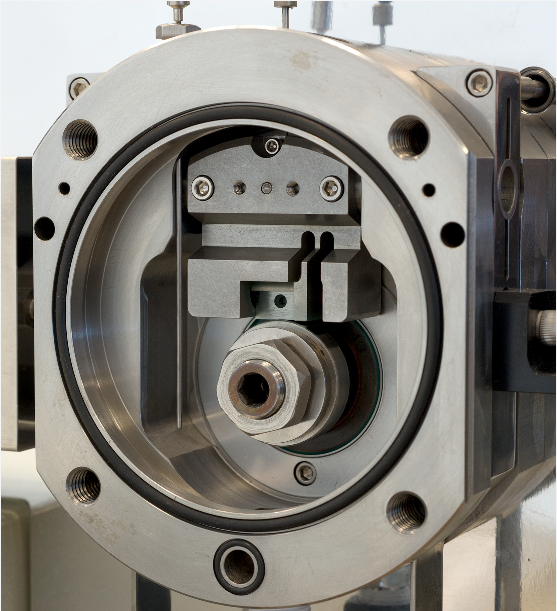

The Block-on-Ring Test Machine is a tribological testing system designed to evaluate friction and wear performance under stable line-contact conditions. Using a Block-on-Ring contact configuration, the system maintains constant linear contact and steady rotational speed, allowing you to reliably simulate real industrial contact conditions.

The machine supports dry and lubricated friction testing for lubricants, coatings, polymers, ceramics, and composite materials. A pneumatic loading system and programmable control enable stepwise or ramped control of load, speed, temperature, and motion mode, ensuring repeatable and standardized wear testing.

Application

You can use the Block-on-Ring Test Machine for the following applications and test specimens:

Friction and wear performance testing of lubricating oils and greases

Wear resistance evaluation of coatings under dry or lubricated conditions

Tribological analysis of polymers, ceramics, and composite materials

Friction and wear testing under high-temperature and low-temperature environments

Simulation of industrial material contact conditions with line contact geometry

Standardized performance evaluation of engineering materials

Research and development testing for automotive components

Quality control testing in mechanical, aerospace, and lubricant development laboratories

Standards

The system is suitable for testing in accordance with the following international standards and methods:

(1) ASTM D2509 — Standard Test Method for Measurement of Load-Carrying Capacity of Lubricating Grease

(2) ASTM D2714 — Standard Guide for Calibration and Operation of Ring-on-Block Wear Test Machines

(3) ASTM D2782 — Standard Test Method for Measurement of Extreme-Pressure Properties of Lubricating Fluids

(4) ASTM D2981 — Standard Test Method for Evaluation of Solid Lubricant Films under Oscillating Motion

(5) ASTM D3704 — Standard Test Method for Wear Characteristics of Lubricating Grease under Oscillating Motion

(6) ASTM G77 — Standard Test Method for Ranking Resistance of Materials to Sliding Wear Using Ring-on-Block Geometry

(7) ASTM G137 — Standard Test Method for Ranking Resistance of Polymeric Materials to Sliding Wear Using Ring-on-Block Geometry

(8) Proposed STM — Wear Testing of Dry Film Solid Lubricants under Unidirectional Motion

Parameters

| Item | Technical Parameters |

|---|---|

| Speed range | Standard: 60–3,600 RPM; Optional: 0.5–7,200 RPM |

| Linear speed | Automatically calculated from shaft speed; programmable RPM setpoints, ramp rates, cycles, and test sequences |

| Load range | Dual-zone pneumatic loading: Low load 10–100 lbs; High load 50–1,300 lbs |

| Temperature range | Standard chamber: Ambient to 200 °C; Optional pressure chamber: Ambient to 250 °C; External chiller for sub-ambient testing |

| Friction force measurement | Electronic load cell, standard range 0–250 lbs; optional low-load range 0–25 lbs |

| Motion modes | Unidirectional rotation or oscillating motion (5°–720°) |

| Test control mode | Time-based, cycle-based, or limit-based automatic shutdown |

| Power supply | 220 VAC, single phase, 50/60 Hz |

| Compressed air | 80 psig, clean and dry |

| Benchtop dimensions | 1,829 × 610 × 762 mm |

| Machine weight | 163 kg |

| Shipping dimensions | 1,220 × 1,016 × 1,067 mm |

| Shipping weight | 246 kg |

Features

(1) Stable line-contact configuration that avoids rapid contact pressure reduction common in point-contact testers

(2) Wide temperature control range supporting high-temperature and optional low-temperature wear testing

(3) Dual-zone pneumatic loading system covering low-load and high-load test requirements

(4) Programmable control of speed, load, temperature, oscillation angle, cycles, and test sequence

(5) High-precision electronic friction force measurement suitable for low-load testing

(6) Support for dry friction and lubricated testing with direct lubricant injection

(7) Multiple motion modes including unidirectional and oscillating motion

(8) Reliable simulation of industrial contact and wear conditions

Accessories

(1) Standard Block-on-Ring adapter

(2) Inclined cylinder contact adapter

(3) Flat specimen contact adapter

(4) Point contact testing adapter

(5) Temperature-controlled test chamber

(6) Optional pressure test chamber

(7) External chiller for low-temperature testing

(8) Electronic load cell for friction force measurement

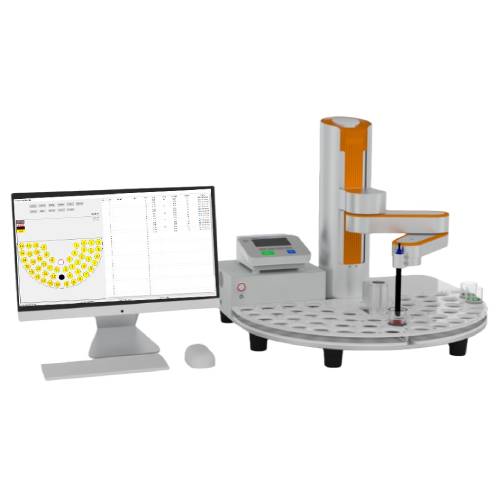

(9) PC-based control and data acquisition system

Test Procedures

(1) Verify that the power supply and compressed air meet system requirements

(2) Install the required contact geometry and test specimens

(3) Set test parameters including speed, load, temperature, oscillation angle, and cycle count

(4) Activate the temperature control system and stabilize the test environment

(5) Apply the specified load using the pneumatic loading system

(6) Start the test and monitor friction force, temperature, and cycle data in real time

(7) Allow the system to complete the programmed test sequence or stop automatically at limit conditions

(8) Gradually unload the specimen and remove it for post-test wear analysis

Maintenance Information

Regularly inspect pneumatic components, seals, and air lines for leakage.

Clean test fixtures, adapters, and lubricant paths after each test series.

Calibrate the electronic load cell and speed sensors at defined intervals.

Inspect wear components and replace them as required to maintain test accuracy.

Disconnect power and air supply before performing any maintenance work.

FAQ

(1) What is this product?

It is a tribological test machine designed to measure friction force, wear behavior, and material performance using a ring-on-block line-contact configuration.

(2) What is this product used for?

You use it to evaluate lubricants, coatings, polymers, ceramics, and engineering materials under dry or lubricated friction conditions.

(3) What is the working principle of this product?

A rotating ring contacts a stationary block under controlled load, speed, and temperature, while friction force is measured in real time to determine wear and friction characteristics.

(4) Why is this product important?

It provides stable and repeatable line-contact testing that closely simulates real industrial wear conditions, improving the reliability of material performance evaluation.

(5) Which industries is this product suitable for?

It is suitable for automotive, mechanical engineering, aerospace, lubricant development, materials research, and industrial quality control laboratories.

Leave Message Get Price