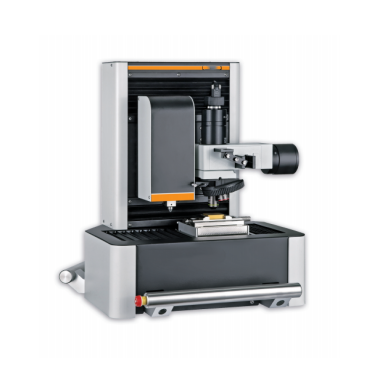

Scratch Hardness Tester

The Scratch Hardness Tester is designed to quantitatively evaluate the scratch resistance and surface strength of coatings, films, and material samples. Using a conical stylus with a variable radius (R 0.005–1.0 mm), the tester applies either continuous or fixed loads to the sample while the stage moves. Scratches can be observed under a microscope or analyzed with optional software for precise quantification of surface durability. This instrument provides reliable, repeatable measurements for both laboratory research and quality control applications.

Application

Primary applications:

Quantitative assessment of scratch and surface hardness

Evaluation of coatings, thin films, pressure-sensitive membranes, and hard or soft layers

Determination of surface fracture strength and wear resistance

Laboratory research, material development, and quality control

Typical tested samples:

Paints and varnishes

Polymer coatings

Thin-film materials

Laboratory-prepared samples for hardness and durability testing

Standards

(1) JIS K 5600 series – Methods of testing paints

(2) ISO 12137-2:1997 – Paints and varnishes – Determination of resistance to surface scratch

Parameters

| Parameter | Specification |

|---|---|

| Scratch Stylus | Conical, R 0.005–1.0 mm (sapphire tip R0.03 mm optional) |

| Test Force Range | Fixed or continuous loading, 0–50 g / 0–100 g / 0–200 g selectable |

| Stroke Length | 100 mm |

| Scratch Speed | 600 mm/min (typical for ISO 12137-2 testing) |

| Sample Size | Flat panel samples, variable dimensions |

| Optional Software | Tribosoft for recording scratch resistance and force analysis |

Features

Supports both continuous and fixed load scratch testing.

Sapphire stylus ensures long-term durability and consistent measurements.

ISO 12137-2 compliant for paints and varnishes.

Measures surface fracture strength by progressively increasing load during scratch tests.

Optional data analysis software (Tribosoft) allows precise quantification of scratch resistance and monitoring of load during scratching.

Capable of simulating pencil hardness testing under 750 g load at 45° inclination.

Surface friction (static and dynamic) can be recorded and analyzed for sliding behavior.

Wide applicability from thin films to hard membranes using variable radius stylus.

Accessories

(1) Fixed load weights: 0–50 g, 0–100 g, 0–200 g

(2) Sapphire conical stylus (R0.03 mm optional)

(3) Microscope or optical observation device (user-supplied)

(4) Optional Tribosoft data analysis software

Test Procedures

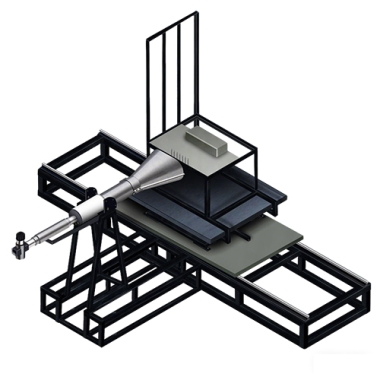

Sample Mounting

Secure the sample on the moving stage ensuring flat alignment.

Load Selection

Choose either fixed load or continuous loading mechanism.

Continuous loading allows stacking of weights for variable total load (e.g., 100 g fixed + 0–200 g continuous = 100–300 g total).

Scratch Test

Stylus moves along the sample for a 100 mm stroke at 600 mm/min (ISO 12137-2).

Observe scratch formation under a microscope or capture force data using Tribosoft software.

Data Evaluation

Determine scratch width, surface fracture load, and overall scratch resistance.

Compare results with standard references or previous measurements.

Optional Tests

Pencil hardness evaluation using 750 g load at 45° angle.

Sliding friction measurements for static and dynamic resistance.

Maintenance Information

Clean stylus and stage after each use to prevent debris accumulation.

Inspect continuous load mechanism for smooth rolling of weights.

Calibrate load and stylus alignment periodically for consistent results.

Replace worn or damaged sapphire stylus tips promptly.

Ensure software updates for precise data acquisition and analysis.

FAQ

1. What is the core advantage of this product?

It provides precise, repeatable evaluation of scratch resistance and surface hardness for a wide range of materials, using both fixed and continuous loading.

2. Are the test results reliable?

Yes. The combination of mechanical continuous loading, sapphire stylus, and optional software ensures highly reproducible and quantifiable scratch measurements.

3. Which international/industry standards does it comply with?

JIS K 5600 series and ISO 12137-2:1997.

4. Why is this product important?

It allows objective assessment of surface durability, scratch resistance, and material hardness, which is critical for coatings, films, and industrial quality control.

5. Which fields is this product suitable for?

Paint and coating R&D

Polymer and thin-film evaluation

Material science laboratories

Quality control in manufacturing

Leave Message Get Price