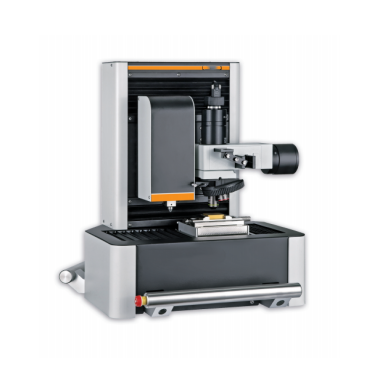

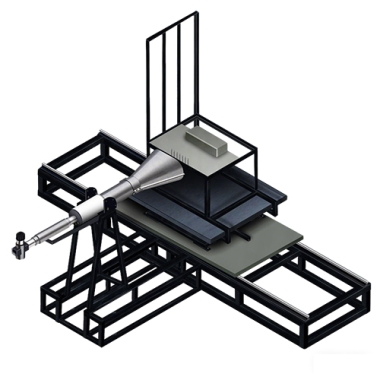

Cookware Scratch Resistance Tester

The Cookware Scratch Resistance Tester is designed to evaluate the scratch and wear resistance of non-stick cookware surfaces. It simulates repetitive handling and mechanical stress by applying controlled loads through a stylus or test pin, performing continuous cycles of movement on the cookware surface. The system ensures that handles and connection components withstand up to 15.000 cycles without deformation or loosening, providing a reliable assessment of durability and coating integrity.

Application

Primary applications

Scratch and wear resistance testing for non-stick cookware

Life-cycle testing of handles, connectors, and moving components

Quality control and material verification for cookware production

Verification of coating durability under repeated mechanical stress

Typical tested products

Non-stick frying pans and pots

Cookware handles and attachments

Ceramic-coated and polymer-coated cookware

Standards

(1) BS7069 Annex A.3 – Scratch resistance test method for non-stick cookware coatings

(2) GB/T 32095.2-2015 – Cookware: Non-stick surface performance and testing, Part 2: Wear and scratch resistance

(3) GB/T 1768-2006 – Paint film wear resistance measurement

(4) GB/T 6739-2006 – Paint film hardness by pencil method

(5) GB/T 23989-2009 – Coating scratch resistance determination

(6) ISO 20502 – Fine ceramics – Scratch resistance evaluation

(7) ISO 6508 – Metallic materials – Rockwell hardness test

(8) ASTM C1624 – Scratch resistance and adhesion testing of ceramic coatings

(9) ASTM D3363 – Pencil hardness testing of coatings

(10) ASTM D7027 – Scratch resistance evaluation of polymer coatings

(11) ASTM G171 – Scratch hardness determination of materials

(12) DIN EN ISO 1518-1 – Scratch resistance measurement of paints and varnishes

(13) DIN EN 1071-3 – Scratch resistance of advanced ceramic materials

Parameters

| Item | Specification |

|---|---|

| Stylus material | Tungsten steel ball tip |

| Stylus diameter | 1 mm |

| Applied load | 5 N ±0.1 N |

| Scratch speed | 0.08 m/s ±0.01 m/s |

| Scratch travel | ≥ 80 mm per stroke |

| Machine dimensions | 700 mm (L) × 350 mm (W) × 404 mm (H) |

| Heating requirement | Non-stick cookware heated to 220 ±5℃ on a 1500 W electric plate (diameter 180 ±20 mm) |

Features

Provides highly repeatable and controlled scratch testing for cookware surfaces.

Supports continuous cyclic testing up to 15.000 strokes without damaging handles or connectors.

Tungsten steel stylus ensures durability and consistent scratch application.

Adjustable speed and stroke length for precise simulation of real usage conditions.

Compatible with infrared non-contact temperature measurement for accurate surface heating.

Compact, robust design suitable for laboratory or production line testing.

Accessories

(1) Tungsten steel stylus (1 mm diameter)

(2) Electric heating plate (1500 W, Ø180 mm recommended)

(3) Infrared non-contact temperature detector (optional)

(4) User manual

Test Procedures

Preparation

Place the non-stick cookware on the designated electric heating plate.

Heat the plate to 220 ±5℃. The temperature should be measured at the center of the pan; a non-contact infrared thermometer is recommended.

Parameter setting

Set stylus force to 5 N ±0.1 N.

Program scratch speed to 0.08 m/s ±0.01 m/s.

Define the scratch stroke length (≥80 mm per stroke).

Running the test

Start the cyclic scratch motion once the cookware reaches the target temperature.

The stylus performs repeated scratches along the predefined path.

Complete the test after reaching the desired number of cycles (up to 15.000).

Post-test inspection

Inspect the cookware surface for scratches, coating damage, and handle integrity.

Record results and verify against performance standards.

Maintenance Information

Keep the tungsten stylus clean and replace if worn or damaged.

Verify the heating plate operates consistently at the required temperature.

Check mechanical components and guide rails for smooth operation.

Avoid overloading or exceeding specified scratch force.

Calibrate stylus force and motion periodically to maintain accuracy.

FAQ

1. What is the core advantage of this product?

It provides precise, repeatable testing of non-stick cookware surfaces, assessing both scratch resistance and mechanical durability of handles under simulated repeated use.

2. Are the test results reliable?

Yes. The instrument combines controlled stylus force, programmed stroke speed, and precise heating, ensuring consistent and reproducible results.

3. Which international/industry standards does it comply with?

BS7069. GB/T 32095.2-2015. GB/T 1768-2006. GB/T 6739-2006. GB/T 23989-2009. ISO 20502. ISO 6508. ASTM C1624. ASTM D3363. ASTM D7027. ASTM G171. DIN EN ISO 1518-1. DIN EN 1071-3.

4. Why is this product important?

Durable non-stick coatings and handles are critical for cookware performance and safety. This tester ensures products meet functional and quality expectations before reaching consumers.

5. Which fields is this product suitable for?

Cookware manufacturers

Material and coating R&D laboratories

Quality control departments

Product certification and testing centers

Leave Message Get Price