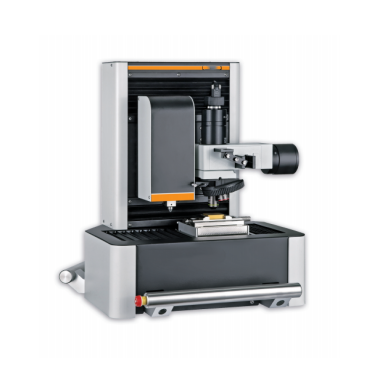

Multifunctional Dynamic Scratch and Wear Tester

The Multifunctional Dynamic Scratch and Wear Tester is designed to evaluate the scratch, wear, and impact resistance of various materials and surfaces. It accommodates both laboratory samples and finished products, whether flat or curved. This versatile tester provides precise, repeatable testing under controlled loads and motion parameters, supporting research, quality control, and product validation across multiple industries.

Application

Primary applications

Scratch, wear, and impact resistance testing for materials and surfaces

Evaluation of automotive interior materials, polymers, and metal coatings

Laboratory research and product quality assurance Testing of both flat and curved samples for industrial or consumer products

Typical tested products

Automotive interior panels and trims

Metal and polymer-coated components

Consumer products with protective surface coatings

Laboratory-prepared material samples

Standards

(1) BMW GS 97034-8 – Automotive interior materials surface tilt test specification

(2) BMW GS 97034-9 – Automotive interior materials surface scratch test specification

(3) GB/T 23989-2009 – Determination of scratch resistance of coatings

(4) GB/T 1768-2006 – Paint film wear resistance measurement

(5) GB/T 12444-2006 – Metallic materials wear test method

(6) ISO 7148 – Metallic materials – Friction and wear test method

(7) ASTM G171 – Scratch hardness determination of materials

(8) ASTM G133 – Reciprocating sliding wear test method

(9) ASTM G99 – Pin-on-disk friction and wear test method

(10) ASTM D7027 – Evaluation of scratch resistance of polymer coatings

Parameters

| Test Function | Technical Specification |

|---|---|

| Test Force Range | 0~30 N (adjustable in 1 N increments) |

| Stroke Length | Up to 120 mm |

| Test Line Speed | Up to 1500 mm/s |

| Cycle Count | 0~999.999.999 (programmable) |

| Sample Type | Sample A: Disk edge, radius 2.5 mmSample B: Pin tip |

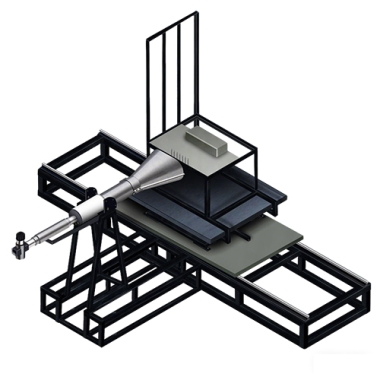

| Working Stage | X-Y working test stage |

| Power Supply | AC 220 V, 50 Hz, 750 W |

Features

Dual control system: PLC + Windows, allowing system switching.

User-friendly interface: 12-inch embedded industrial computer with Chinese/English option.

Supports Wi-Fi connection to printers for automated reporting.

Real-time curve display for monitoring scratch and wear performance.

Capable of testing both flat and curved samples with interchangeable test heads and media.

Flexible programming for test mode, speed, stroke, and applied load.

Supports both wet and dry testing methods.

Accessories

(1) Various test heads for different surface types

(2) Sample clamps for flat and curved specimens

(3) Test media (textiles, abrasive pads, pins, or disks)

(4) User manual

Test Procedures

Sample Preparation

Secure the sample on the X-Y test stage using appropriate clamps.

Ensure curved samples are properly supported to avoid deformation.

Parameter Setting

Select test mode (scratch, wear, or impact) in software.

Program test speed, stroke length, applied load, and number of cycles.

Confirm testing medium or stylus is correctly installed.

Running the Test

Start the program; the tester executes pre-set motion patterns.

Monitor test curves and data in real-time.

Upon completion, the system automatically stops and returns to initial position.

Post-Test Evaluation

Inspect the sample surface for scratches, wear, or impact damage.

Export test data and generate reports as needed.

Maintenance Information

Regularly clean and inspect test heads and working stage.

Ensure mechanical guides and X-Y stage operate smoothly.

Calibrate load and motion parameters periodically for accuracy.

Replace worn or damaged test heads immediately.

Keep software updated for optimal functionality.

FAQ

1. What is the core advantage of this product?

It provides multi-functional testing of scratch, wear, and impact resistance for flat and curved samples, supporting highly accurate and repeatable results.

2. Are the test results reliable?

Yes. The tester’s programmable control, precise load application, and adjustable speed ensure consistent and reproducible performance data.

3. Which international/industry standards does it comply with?

BMW GS 97034-8/9. GB/T 23989-2009. GB/T 1768-2006. GB/T 12444-2006. ISO 7148. ASTM G171. ASTM G133. ASTM G99. ASTM D7027.

4. Why is this product important?

It enables comprehensive evaluation of material durability, coating integrity, and surface wear resistance, critical for automotive, polymer, and consumer product industries.

5. Which fields is this product suitable for?

Automotive interior material testing

Polymer and coating R&D laboratories

Quality control departments in manufacturing

Material research and development centers

Leave Message Get Price