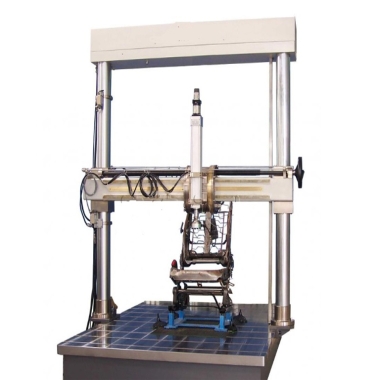

Automobile Seat Frame Strength Test Bench

The Automobile Seat Frame Strength Test Bench is designed to evaluate the structural strength and durability of automotive seat frames, seat fixers, and headrests under various load conditions. It simulates real-world forces, including forward, backward, and torsional loads, to ensure seat components comply with international and national safety standards. The test bench is widely used by automotive OEMs, seat manufacturers, and testing laboratories for performance verification, quality control, and R&D purposes.

Features

High loading capacity to simulate extreme conditions, including high-magnitude static and dynamic loads.

Supports multiple loading methods such as horizontal forward, horizontal backward, and torsion to cover a variety of test scenarios.

Computer-controlled servo system ensures precise loading and measurement.

Real-time data acquisition and processing with automatic test report generation.

Configurable number of test cycles for durability and fatigue evaluation.

Durable mechanical structure designed for stable long-term operation.

Safety features including emergency stop, overload protection, and compliance with electrical safety standards.

Standards

GB 15083-2006 – Automotive seats, seat fixers, and headrest strength requirements and tests.

GB 13057-2003 – Strength of passenger car seats and vehicle fasteners.

QC/T 740-2005 – Passenger car seat assembly.

QC/T 633-200X – Bus seat requirements.

JT/T 460-2001 – Passenger car seat back angle adjuster technical requirements.

FMVSS 207 – Federal Motor Vehicle Safety Standard, strength requirements for seat backs and adjustment devices.

ECE R17 – ECE regulation on the strength of car seats and seat belt anchors.

Technical Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | Three-phase AC 380±10%, Single-phase AC 220±10% |

| Force Sensor Accuracy | ±1% FS |

| Measuring Range | 0–2000 N |

| Test Frequency | 5–30 cycles/min (adjustable) |

| Floor Area | 3500 × 3500 × 2500 mm |

| Control Mode | Computer-controlled servo system |

| Data Acquisition | Real-time recording and automatic test report generation |

Optional Accessories

Adjustable seat fixtures for different seat types

High-precision force sensors for extended measurement range

Data acquisition and analysis software

Protective covers and anti-vibration mounting base

Calibration kits for sensors and load cells

Leave Message Get Price