Film impact tester

Product Introduction:

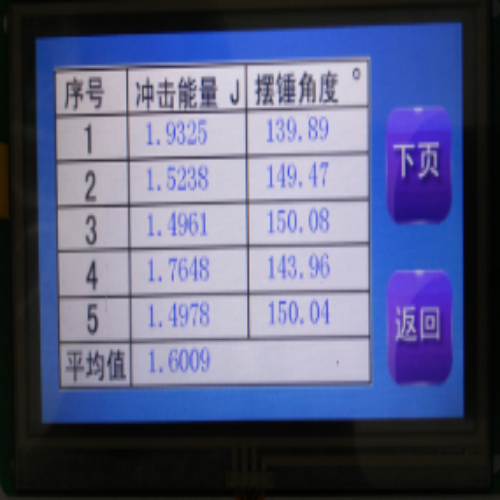

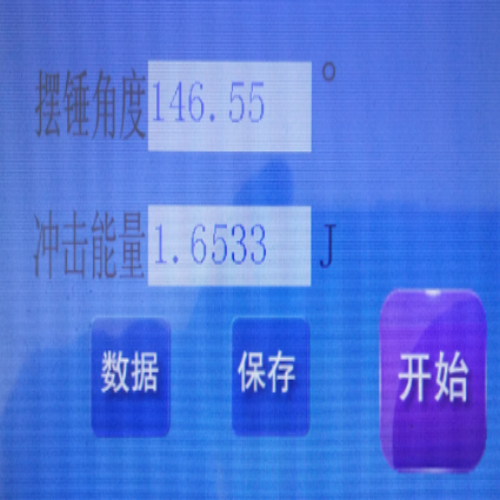

The film impact testing machine, through the hemispherical punch at a certain speed, impacts and passes through the film sample, measures the energy consumed by the punch, and evaluates the anti-pendulum impact energy of the film sample.

The sample to be measured is placed in the middle of two splints to clamp, and the pendulum is adjusted by counterweight to form enough mechanical energy to impact the surface of the sample to be measured during the impact process to break down or not break down the sample to be measured. The energy borne by the sample to be measured is the loss part of the total mechanical energy formed by the pendulum during the impact process, and is read out on the dial through the pointer. The design principle of this instrument conforms to ASTMD3420-2014 and GB8809-2015 standards.

Performance parameters:

- Full range of dial: 3J/(30cm.kgf)

- Maximum impact energy: 3J

- Hammer diameter: Φ25.4mm: suitable for test specimens with diameter of medium 50-60 (Class A test in the standard); Φ19mm: Suitable for testing specimens with a diameter of 89 (Class B test in the standard)

- Reading dial minimum scale value: 0.020J/ grid (0.20cm.kgf)

- Specimen clamp diameter: Φ89mm, Φ60mm

- Swing range: R300mm

- Swing Angle: 90°

Leave Message Get Price