Orthopedic Bioresorbable Fixation Fatigue Tester

Standards:

ISO 12189

ASTM F2502

ASTM F382

Scope of Application:

Evaluating mechanical properties: By simulating the stress conditions of human bones and the dynamic loads experienced by implants, this tester can be used to measure the fatigue life of bioresorbable internal fixation plates and screws under cyclic tension, compression, bending, and potentially torsional stresses. While the user specifically mentioned torque, fracture torsion angle, and torsional yield strength (which are typically measured in static torsion tests), a versatile fatigue tester might also be capable of performing these static tests, or the user's description refers to the importance of evaluating these properties as part of the overall mechanical characterization supported by this type of equipment. The primary focus of a fatigue tester for these devices is their performance under repeated loading.

Optimizing design: Based on the test results obtained from fatigue testing, particularly when combined with static mechanical property data and degradation studies, the design of internal fixation plates and screws (including material composition, polymer chain structure, processing methods, plate geometry, screw thread design, and hole patterns) can be optimized to ensure they maintain sufficient strength and stability throughout the required bone healing period while resorbing predictably and safely.

Quality control: During the production process, conducting mechanical property tests, including fatigue testing, on bioresorbable internal fixation plates and screws is crucial to ensure they meet quality standards and reduce the defective-product rate. Consistent mechanical performance, especially fatigue resistance over time as the material degrades, is vital for the reliability and safety of each manufactured implant.

Product Advantages:

Evaluates Fatigue Life Over Time: Crucially assesses how the fatigue resistance of bioresorbable implants changes as they degrade, ensuring sufficient strength is maintained during bone healing.

Simulates Physiological Loading and Environment: Enables testing under cyclic stresses relevant to orthopedic applications and in a simulated body fluid at physiological temperature, accelerating and controlling the degradation process.

Provides Crucial Mechanical Data: Yields quantitative measurements of fatigue life, stiffness, and strength under dynamic loading, essential for design validation and regulatory approval.

Supports R&D for Novel Materials: Indispensable for developing and testing new bioresorbable polymers, composites, and implant designs with tailored degradation rates and mechanical properties.

Essential for Quality Control: Provides a standardized method for ensuring the consistent mechanical performance and degradation behavior of manufactured bioresorbable implants.

Contributes to Patient Safety: By ensuring implants maintain mechanical integrity during healing, the tester helps reduce the risk of implant failure and associated complications.

Product Features:

A dynamic testing frame (e.g., servo-hydraulic or electrodynamic) with the capacity and stiffness required to apply physiological loads over millions of cycles.

Capabilities for applying cyclic loads in tension, compression, and bending. Some versatile systems may also offer torsional or multi-axial loading capabilities, or may be configured with separate modules for these tests.

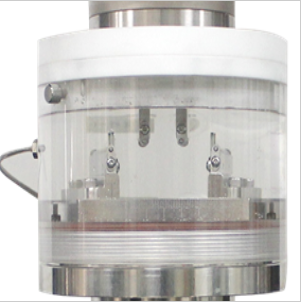

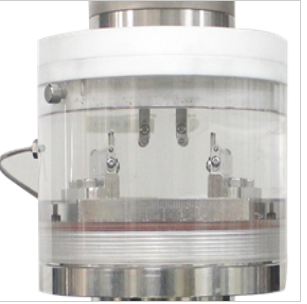

Specialized fixtures designed to hold bioresorbable plates and screws in configurations that simulate their implantation and allow for the application of relevant fatigue loads. These fixtures often incorporate simulated bone material (e.g., rigid polyurethane foam or other biodegradable substitutes) for screw insertion.

Dynamic load cell(s) for accurate measurement of the applied cyclic force(s).

Displacement sensor(s) or the testing machine's measurement system to record deformation of the implant construct under load.

Advanced control system capable of applying various cyclic waveforms at specified frequencies and load or displacement amplitudes, and controlling the number of cycles.

A cycle counter to accurately record the total number of load cycles applied.

Technical Parameters:

Static Load Capacity (if applicable): (e.g., ranging from 1 kN to 20 kN or more, depending on the device)

Dynamic Load Capacity (Tension/Compression/Bending): (e.g., typically ranging from ±0.5 kN to ±10 kN or more, depending on the expected loads for the specific implants)

Dynamic Torque Capacity (if applicable): (e.g., ranging from ±5 Nm to ±20 Nm or more)

Frequency Range: (e.g., up to 10 Hz, 20 Hz, or higher, as specified by relevant testing standards)

Load Control Accuracy: (e.g., ±1% of set load or better)

Displacement Control Accuracy: (e.g., ±1% of set displacement or better)

Angular Displacement Control Accuracy (if applicable): (e.g., ±0.1 degrees or better)

Type of Loading Capabilities: (Tension, Compression, Bending, potentially Torsion or multi-axial, depending on the system configuration)

Maximum Number of Cycles: (Designed for very long-term testing, e.g., up to 5 million, 10 million, or even significantly more cycles depending on the simulated healing period)

Actuator Stroke (Linear and/or Rotational): (Sufficient for applying required displacements/angles under cyclic loading)

Environmental Chamber/Fluid Bath Temperature Range: (e.g., Ambient to 40°C or higher, with precise control at 37°C)

Environmental Chamber/Fluid Bath Temperature Accuracy: (e.g., ±0.5°C or better)

Environmental Control Features: (Ability to hold and maintain fluid level, material compatibility with simulated body fluid, potentially fluid circulation or exchange)

Sample Size Capacity: (Able to accommodate various bioresorbable plate designs and sizes with associated screws and simulated bone models)

Power Supply: (e.g., AC 220V or 380V, 50/60 Hz, potentially with a hydraulic power unit if servo-hydraulic)

Leave Message Get Price