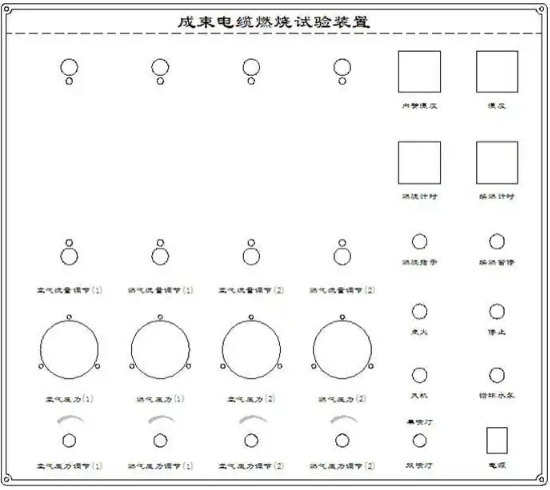

Bundle wire and cable burning test machine

Technical parameters:

1, shape (overall space) size: 2500mm(length)*3200mm(width)*4500mm(height)

2, material: heat transfer coefficient of 0.7W∙m-2∙K-1 thermal insulation, that is, coated 65mm thick mineral fiber stainless steel plate

3, air source: control the gas flow through the box air is (5000±500) L/min, the test process can stabilize the air flow rate. A spraying device that forcibly stops burning after the test is completed

4, steel ladder type: width 500mm standard steel ladder width 800mm wide steel ladder

5. Discharge purification device: the test box has a collection and washing smoke device that does not change the air flow through the test box

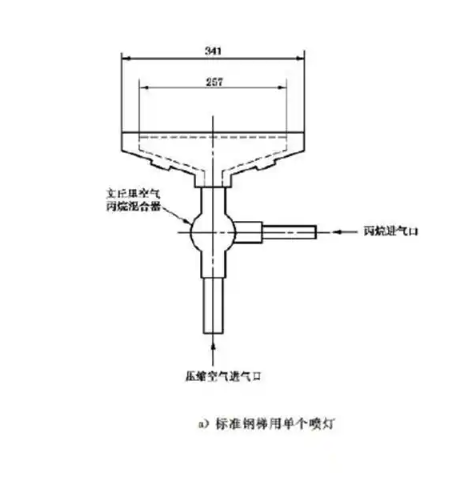

6, ignition source: including one or two belt type propane gas burner and its supporting flow meter and venturi mixer. The fire supply surface shall be drilled with 242 flat metal plates with a diameter of 1.32mm aperture, with a center distance of 3.2mm and staggered in three rows of 81, 80 and 81 holes, respectively, distributed within a nominal size of 257×4.5mm. In addition, a row of small holes are opened on each side of the spout plate, and these guide holes can keep the flame burning steadily.

a) Each burner is equipped with a rotameter to accurately control the propane and air inflow rate.

b) Under the reference conditions of 100kPa and 20℃, the airflow rate of the test:

Air (77.7±4.8) L/min Propane (13.5±0.5) L/min

7, ignition source position: the torch is placed horizontally, away from the front surface of the cable sample (75±5) mm, away from the bottom of the test box (600±5) mm, and symmetrical with the axis of the steel ladder. The ignition point of the blowtorch should be located in the center between the two rungs of the steel ladder, and at least 500mm away from the lower end of the sample

8, observation window: tempered glass observation window, surrounded by stainless steel edge

9, exhaust system: spiral exhaust fan 2, sealing push and pull plate 2.0mm stainless steel

10, air inlet: 1 (Phi 160mm)

11, the bottom fixed frame: 40mm*40mm square pass production

Leave Message Get Price