Helmet Webbing Micro - displacement Friction Testing Machine

Standard

- ECE R22.05 (UN/ECE regulation for motorcycle helmet safety and webbing durability)

- ISO 10256-7 (Headgear testing – Retention system abrasion and fatigue resistance)

- EN 1078 (Helmets for cyclists – Webbing micro-movement specifications)

Product Advantages

- Multi-Functional Testing

- Abrasion simulation: 10,000-cycle fatigue testing replicates 5+ years of real-world use.

- Micro-displacement analysis: Captures 0.001mm webbing slippage (μm-level precision).

- High-Speed Automation

- 2Hz cycle frequency: Completes 5,000-cycle tests in 42 hours (non-stop operation).

- Electromagnetic actuators: Ensure repeatable 100mm/50mm stroke control.

- Precision Data Acquisition

- Laser displacement sensor: 0.001mm resolution tracks webbing movement.

- Load cell array: Monitors buckle tension (0–500N, ±0.5% accuracy).

- User-Centric Design

- 7" touchscreen: Intuitive interface with multi-language support (EN/DE/ZH/ES/FR).

- Quick-swap fixtures: Accommodates 25–50mm webbing widths in seconds.

- Safety First Engineering

- Overload protection: Halts tests if forces exceed 600N (20% safety margin).

- Emergency stop: Instantly deactivates actuators during malfunctions.

Product Features

Abrasion Testing Module

- Reciprocating Actuator:

- 100mm/50mm stroke: Adjustable for glove-friendly and high-wear testing.

- 2Hz frequency: Simulates rapid webbing movement (7,200 cycles/day).

- Friction Surface:

- Sandpaper anvil: P80 grit for accelerated abrasion testing.

- Self-lubricating guides: Minimizes parasitic friction (μ < 0.05).

Fatigue Testing Module

- Buckle Endurance Rig:

- 500N load cell: Tests clip retention under dynamic loads.

- Cycle counter: Tracks 1–10,000 cycles with interruptible memory.

Data Acquisition System

- Sensors:

- Laser displacement: 0.001mm resolution, 50mm range.

- Triaxial accelerometer: Detects buckle vibration (±2g accuracy).

- Software:

- WebbingPro Suite: Auto-generates ECE R22.05/ISO 10256-7 reports.

- Spectral analysis: Identifies wear patterns via FFT (Fast Fourier Transform).

Safety Systems

- Interlocked enclosure: Prevents access during testing (Category 3 safety rating).

- Auto-calibration: Verifies stroke/force accuracy before each test.

Technical Parameters

| Specification | Details |

|---|---|

| Stroke Range | 100mm (standard), 50mm (low-wear) |

| Cycle Frequency | 2Hz (7,200 cycles/day) |

| Max Cycles | 10,000 (abrasion), 5,000 (fatigue) |

| Load Capacity | 500N (±0.5% accuracy) |

| Displacement Resolution | 0.001mm (50mm range) |

| Power Requirements | 220V/50Hz, 800W (single-phase) |

| Footprint | 600mm (L) x 500mm (W) x 1,200mm (H) |

| Weight | 80kg (net) / 100kg (with accessories) |

Accessories Included

- Webbing Fixtures – Quick-release clamps for 25–50mm widths.

- Calibration Kit – NIST-traceable force gauge and laser interferometer.

- Abrasion Media – P80 sandpaper anvil (10-pack).

- Software License – Lifetime access to WebbingPro (cloud-connected with API for integration with QMS systems).

- Installation & Training – On-site setup by certified engineers + 8hrs virtual training for operators.

- Documentation – Multilingual user manual and ECE R22.05 compliance guide

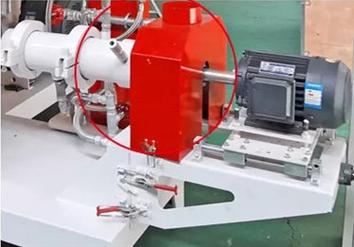

Helmet Webbing Micro - displacement Friction Testing Machine Display:

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price