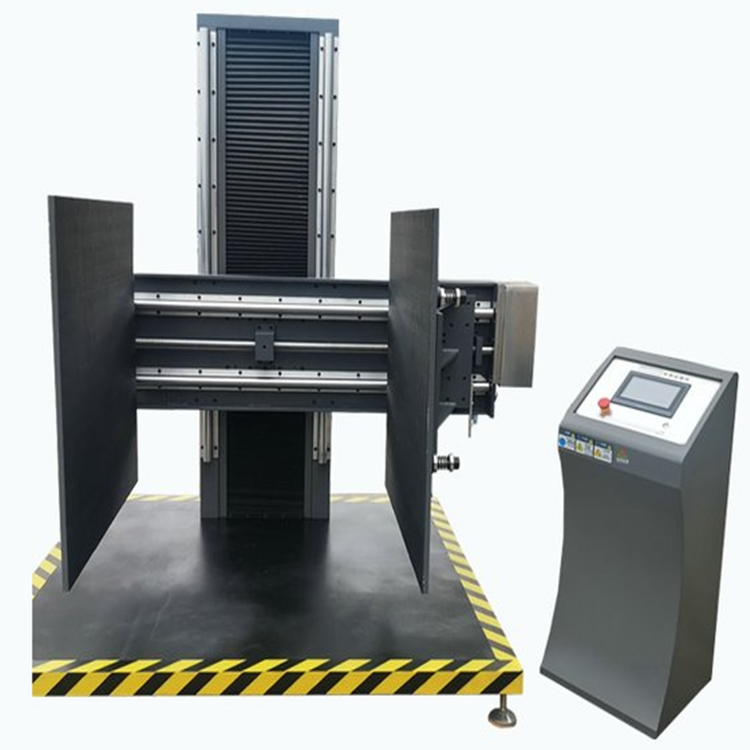

Gripping tester

Product introduction

This machine mainly aims at the ability of the product to withstand the pressure of

lead from the car when the product is packed in the warehouse or truck, train, etc., so as

to evaluate the damage of the product.

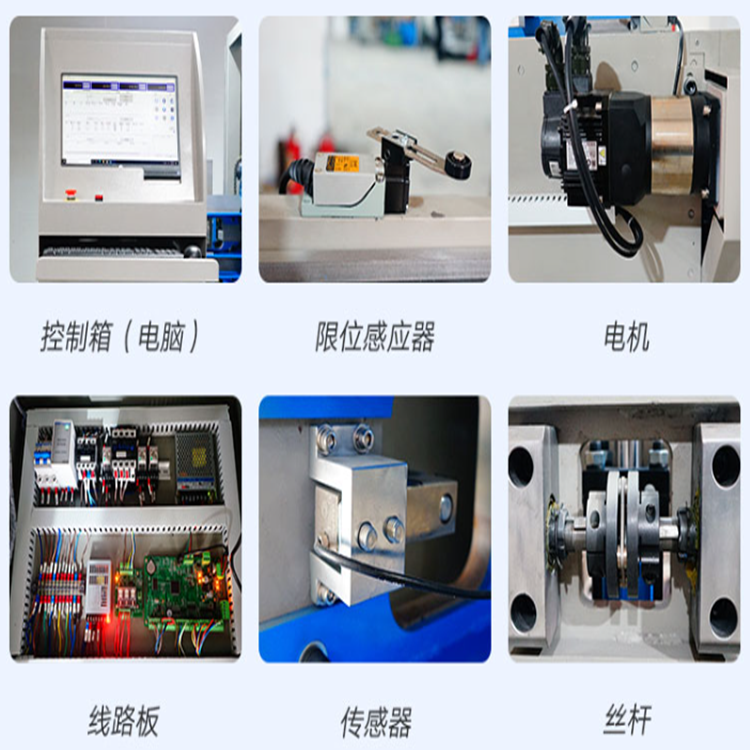

This machine adopts servo motor control, full computer operation, high-grade configuration.

Tests are customized according to ASTM D6055, U.S., SEARS, corporate standards, or

customer specified non-standard requirements.

Scope of application

Applicable to all product packaging testing and verification. The main test is that the

product packaging is subjected to horizontal pressure during transportation and storage

The deformation of the force and the protection ability of the packaging inside the

package, so as to improve the packaging design.

Technical parameter

Sample shape: parallelepiped transport package

Maximum test weight: 100kg

Clamping pressure: 400——3000Lb(adjustable) pressure can be applied on the

corresponding surface according to the handling diagram on the test sample

Clamping plate surface size: 1100x1100mm(L/W)

Test space size: 1000x1000x1000mm(length, width and height)

Clamping plate height adjustment: 0-1000mm can be set

Lifting speed: 10-500mm/mi adjustable

Clamping speed: 10-50mm/min adjustable

Splint expansion width: 200——2000mm

Transmission mode: Japan Panasonic servo motor (left and right clamps)

Base plate size: 2000x1900mm

Protection device: leakage protection limit device

Cleat requirements: Two gripper plates in the working state (2000 pounds) to ensure

smooth without deformation. The two splints are parallel to each other, and the splints are

vertical to the floor. The thickness of the splint shall not be less than 20mm

Force corrector: With force value display, used to correct the clamping pressure

Force accuracy: national standard 1.6 level

Leave Message Get Price