Fabric Tearing Strength Test

Tearing strength:

A fabric tears when it is snagged by a sharp object and the immediate small puncher is converted into long rip by what may be a very small extra effort. It is probably the most common type of strength failure of fabrics in use. It is particularly important in industrial fabrics that are exposed to rough handling. (E.g. Tents, Sacks, Parachutes, etc.) In some applications low tear strength is require, e.g. Adhesive tape, bandages, etc.

Tear strength is the strength required to start or continue the tear in a fabric under specific condition & tearing force is the required to continue a tear previously started in a fabric. The tear resistance test on fabrics or tear strength is measured to check how the material can withstand the effects of tearing or cuts when in tension. The tear strength is measured as per the ASTM D412 standard test method, which is also used to measure tensile and elongation.

Importance of tear strength test on fabrics:

The tear strength is the resistance of fabric against tearing. The tear strength is vital for the textiles, bulletproof jackets, worker jeans, tents, apparel, sacks, and industrial applications. If the tear strength is high, means punctures in the fabrics do not propagate easily. The tear strength is vital in the industrial textiles as heavy duty work is performed.

Factors affecting the tear strength are as follows:

The GSM of the fabric indicates the tear strength. High the GSM means more the tearing strength.

The strength of the yarn has a direct relation to the tearing strength of the fabric. More the yarn strength means more tear strength.

Weave designs mean the plain weave could have lowest tear strength. Similarly, the spun yarn has low tear strength as compared to filament yarn.

The knitted fabric is less strong as compared to woven fabric.

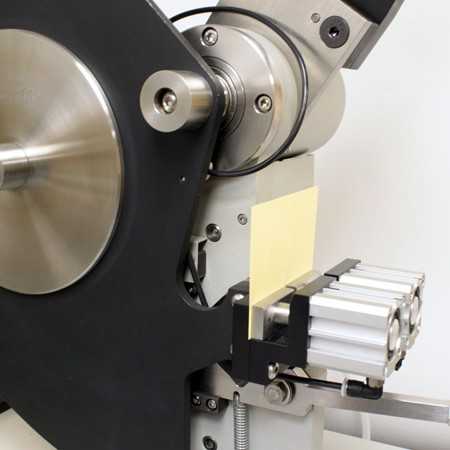

The tearing strength tester is an appropriate tool to measure the tear resistance of various materials including textiles and fabric

Working Procedure:

The apparatus consists of a sector shaped pendulum carrying a moving sample clamp & a fixed clamp on the frame.

When the pendulum is in the raised to starting position, the specimen is transferred between the two clamps.

The tear is started by a slit cut in the specimen between the clamps.

The pendulum is then released & the specimen is torn as the moving clamp, moving away from the fixes clamp.

The pointer attached to the pendulum, which is graduated to read the tearing force directly.

2018-06-14 16:23