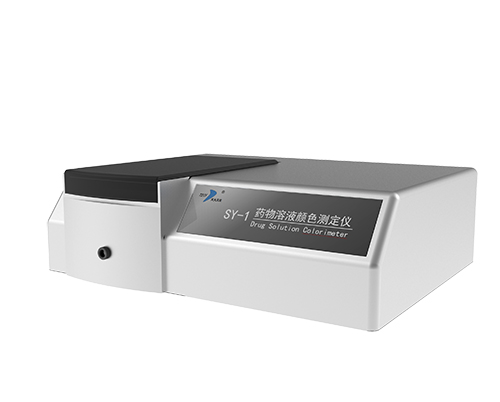

Daily maintenance of SY-1 drug solution color tester

The SY-1 drug solution color meter uses the principle of spectral measurement, is equipped with exclusive color measurement software and a database of pharmacopoeia standard colorimetric solutions, and can accurately measure the color of drug solutions. It is widely used in the field of drug quality control.

The following aspects should be noted in the daily maintenance of SY-1 drug solution colorimeter:

Cleaning and maintenance

- **Instrument surface**: Use a soft cloth to gently wipe the surface of the instrument to remove dust and stains. Do not use chemical solvents or corrosive cleaners.- **Optical system**: Regularly clean the lenses and filters in the optical system to improve the accuracy and sensitivity of the instrument. Use special lens paper or soft cloth when cleaning to avoid scratching the optical components.

Calibration check

- **Regular calibration**: Over time, the accuracy of the instrument may be affected. Standard samples should be used for regular calibration to ensure that the calibration results are accurate.

- **Component inspection**: Regularly check the light source, detector and other components of the instrument to ensure that they are working properly and are not affected by damage or aging. If there are any problems, replace the aging or damaged components in time.

Environmental requirements

- **Temperature and humidity control**: The instrument should be placed in a dry and well-ventilated environment, with the temperature maintained at 15℃-35℃ and the relative humidity not exceeding 85%. Avoid direct sunlight and high temperature and high humidity to prevent the performance of the instrument from being affected.

- **Anti-electromagnetic interference**: When using, keep away from places with strong electromagnetic interference, avoid drastic changes in the external environment of the instrument, such as light flickering, rapid temperature changes, etc., to prevent the measurement accuracy from being affected.

Cuvette maintenance

- **Cleaning**: The cuvette should be cleaned in time after use to avoid sample residue. It can be cleaned with alcohol or special detergent, and then wiped clean with a clean wet cloth. When cleaning, cross contamination between cuvettes should be prevented.

- **Inspection**: Check whether the cuvette is clean, scratch-free, and crack-free. If there are stains, scratches or cracks, it should be replaced in time. At the same time, ensure the matching of the cuvette. Different models of cuvettes may affect the accuracy of the measurement results.

Other precautions

- **Standard operation**: Operate strictly in accordance with the instrument's operating procedures to avoid damage to the instrument or inaccurate measurement results caused by misoperation.

- **Data backup**: After the measurement is completed, back up the measurement data to a computer or other storage device in time to avoid data loss.

- **Maintenance when not in use**: When the instrument is not in use for a long time, it should be protected with a dust cover and powered on regularly for preheating to prevent the electrical components from getting damp or damaged. If it is not in use for a long time, the battery should be removed to avoid damage to the instrument.

Technical parameters:

Light source: Full-band balanced LED composite light source (CLEDs), including the commonly used standard light sources D65 and C in pharmacopoeia

Lighting mode: 0/0 (vertical irradiation, vertical reception)

Observer angle: 2°/10°

Measurement wavelength range: 400~700nm

Wavelength interval: 10nm

Sensor: Dual optical path array sensor

Measurement aperture: about 10mm

Color measurement liquid addition amount: not less than 1.5ml

Measurement time: 0.5 seconds

Measurement interval time: 2 seconds

Absolute error of measuring the three stimulus values X, Y, Z of pure water: ≤0.1

2024-12-27 13:04