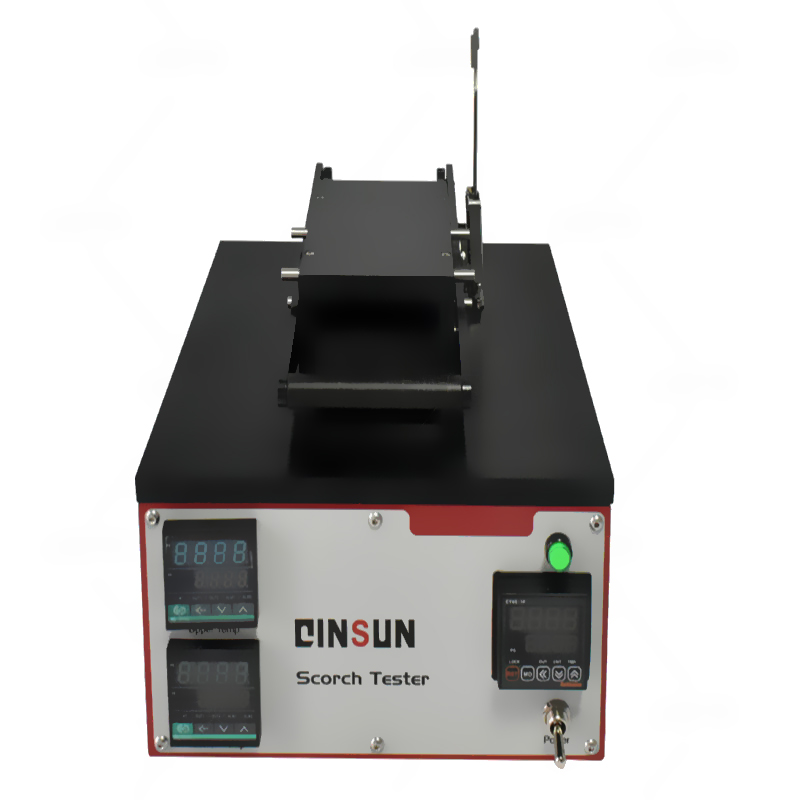

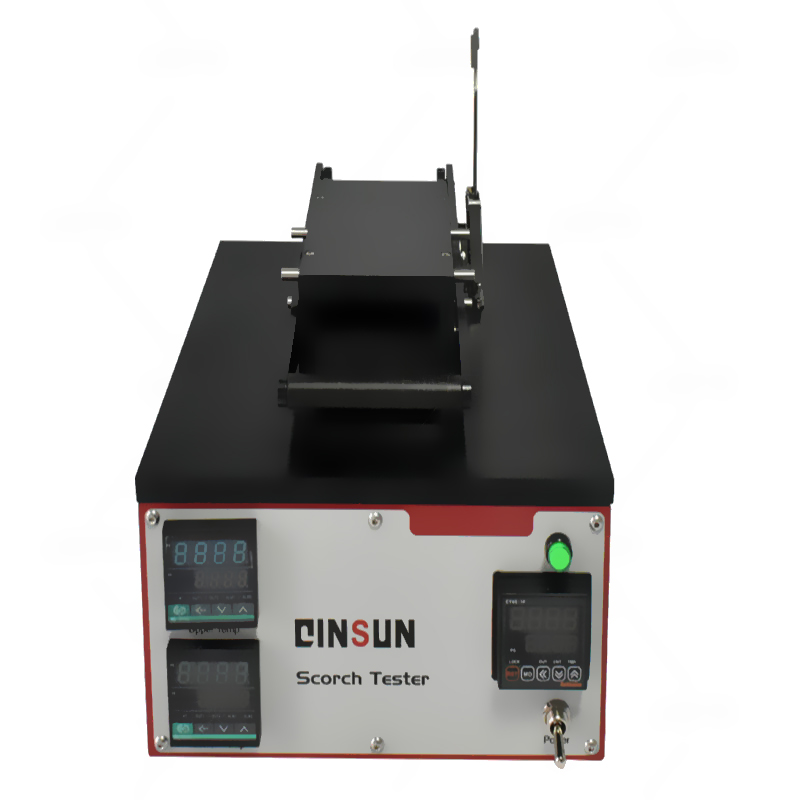

Test principle of ironing resistance sublimation color fastness tester

The ironing sublimation color fastness tester is suitable for measuring the color fastness to hot pressing, ironing and dry heat (sublimation) of various colored textile materials and textiles, and can also test the dimensional stability of fabrics during hot pressing and dry heat treatment.

Shanghai Qianshi Precision Electromechanical Technology Co., Ltd. was established in 2012, focusing on R&D, design and production of textile testing instruments, providing textile testing instruments and services for academic research units and testing institutions, Shanghai Qianshi is currently one of the more competitive and R&D strength of textile testing instrument manufacturers, R & D team composed of a group of experienced engineers, we are in line with wholeheartedly customer service, and strive to promote textile testing instrument technology innovation.

Applicable Standards:

ISO 105 X 11 P01,BS1006,AATCC92114117133,GB/T5718、6152,DIN 54022、54060,JIS L0879、L0850

Test Principle:

Dry pressure test: A dried fabric specimen is heated at a specific temperature, time, and load.

Semi-dry pressure test: The dried fabric specimen is first wrapped in a wet end-dyed cotton cloth and then heated at a specific temperature, time, and load.

Wet pressure test: The soaked fabric specimen is first wrapped in a wet end-dyed cotton cloth and then heated at a specific temperature, time, and load.

Experimental Parameters:

1. Sample heating area: 50mm×110mm

2. Sample pressure: 4kPa±1kPa

3. Time setting: 0.01s~99.99H

4. Temperature setting: any setting from room temperature to 220°C

5. Heating time: less than 30min at room temperature to 110°C

6. Experiment hot plate: W100×D40mm aluminum (the same as the top and bottom)

7. Temperature adjustment: digital temperature mediator, min display 1°C (one up and down)

8. Heater: cartridge heater 100V150W (one upper and lower)

Technical features:

1. The sample is placed between the upper and lower heating plates, and the temperature of the upper and lower heating plates is accurately controlled by an independent controller, and the spacing of the heating plates and the weight of the upper test piece are controllable.

2. The test temperature range is 120-230°C, with timing alarm function, and the sample time can be accurately controlled.

2024-12-02 14:34