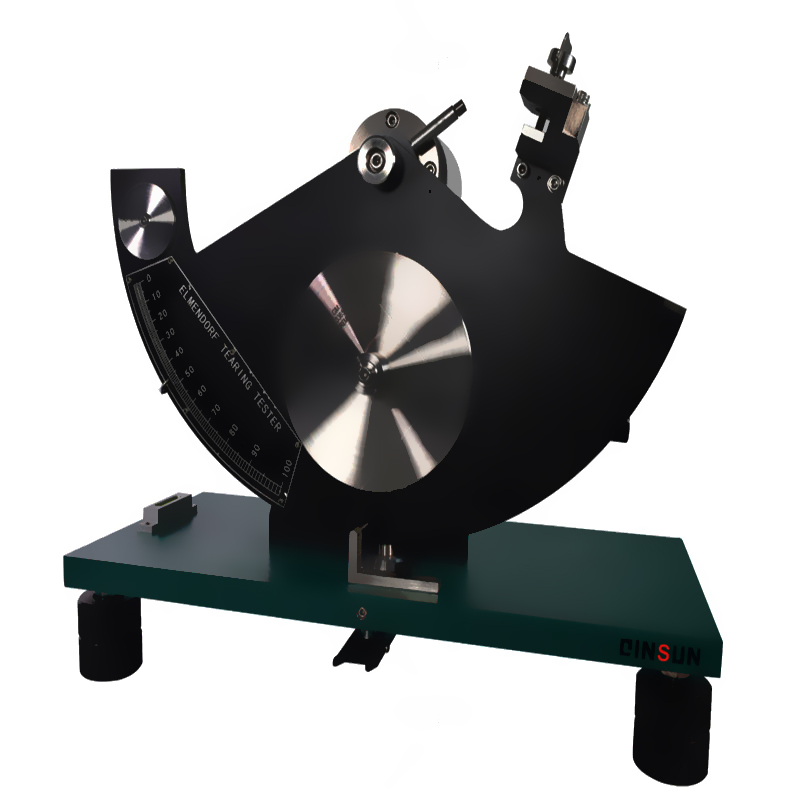

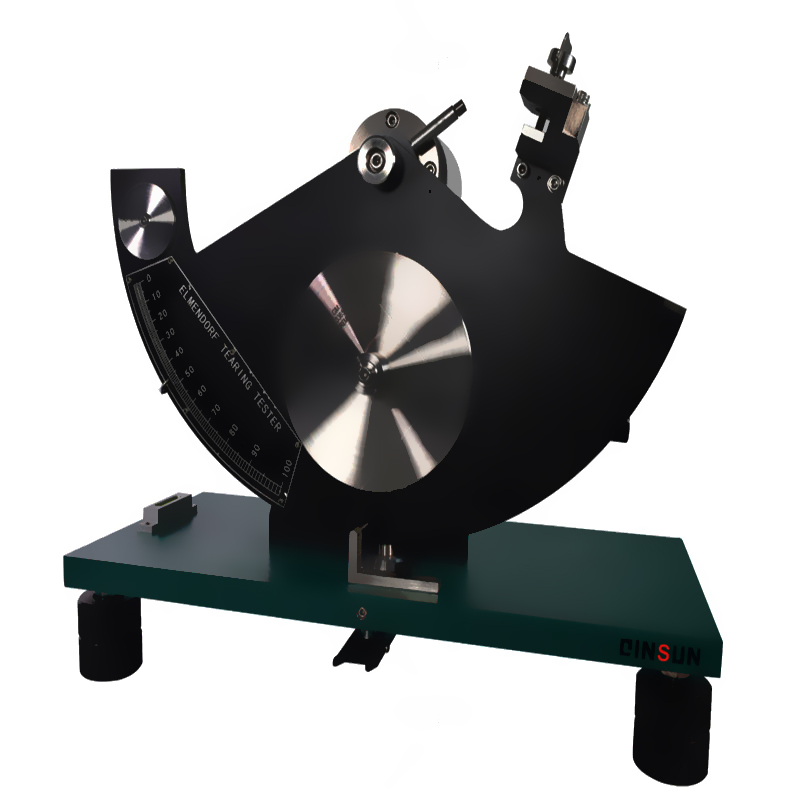

G008 Manual Tear Strength Tester Experimental Principle

G008 Manual Tear Strength Tester is a manual tester used to test the impact tear strength of textiles, woven fabrics, nonwoven fabrics, and coated fabrics. It can also be used for silk, cotton, paper, cardboard, and single-layer and multi-layer corrugated cardboard.

Shanghai Qianshi Precision Electromechanical Technology Co., Ltd. was established in 2012. It focuses on the research, development, design, and production of textile testing instruments, and provides textile testing instruments and services for academic research units and testing institutions. Shanghai Qianshi is currently one of the most competitive and R&D-capable textile testing instrument manufacturers in China. The R&D team is composed of a group of experienced engineers. We are committed to serving customers wholeheartedly and striving to promote technological innovation in textile testing instruments.

Applicable standards:

ASTM D295, D752, D1424, D1922, D5734, TAPPI T414, T496, BS 4253, BS 4468, CPPA D.9, DIN 53862, 53128, ISO 1974, 9290, EN21974, SCAN P11

Experimental principle:

When the single-seam method is used for tearing, a stress triangle is formed at the tear of the fabric. When the stressed weft yarns in the sample gradually separate up and down, the warp yarns that are not directly stressed begin to have some relative sliding with the stressed weft yarns, and gradually move closer to form an approximate triangular area. At the bottom of the tear, the warp yarns in the stressed triangle are jointly subjected to tension, among which the warp yarns at the front of the base of the triangle are subjected to greater stress, and the stress of other warp yarns gradually weakens according to a certain load difference.

Due to the friction resistance between yarns, sliding is limited. During sliding, the tension of the warp yarn increases rapidly, and the deformation elongation also increases sharply. When the first warp yarn constituting the base of the force triangle is stretched to the breaking elongation, this warp yarn breaks and the stress state of the second warp yarn is immediately converted to the state before the first warp yarn breaks. This is repeated, and the warp yarns break one after another, forming a knife-like fracture surface. It can be seen that when the single-seam method is torn, the broken yarn is the yarn of the non-tension system, and the direction of the tensile force is perpendicular to the original axis of the broken yarn. The special pendulum can increase the weight up to 64,000mN for testing thick textiles, and a heavy sample cutter should also be used.

2024-11-22 11:33