Study on Thermal Comfort of Double-layer Thermal Underwear of Sweating Fabric Manikin (Walter)

The volume of the air layer between the clothing and the human body has an important influence on the thermal and moisture resistance of the clothing. Using a standing Sweating Fabric Manikin (Walter) to measure the thermal resistance of loose trousers and tight trousers respectively. Through comparison, it is found that the thermal resistance of loose trousers is greater than that of tight trousers under the same conditions, and the thickness of the air layer in the clothing is considered. It is an important factor that determines the thermal resistance of clothing. Y. S. Chen et al. used a sweating thermal manikin to study the influence of the amount of jacket relaxation on the thermal and moisture resistance, and found that in a smaller air layer, the thermal and moisture resistance of the jacket gradually increased. In the research on the influence of clothing looseness on its thermal comfort, most of them are limited to the measurement of clothing thermal resistance, while the measurement of clothing moisture resistance is relatively limited. This research takes men’s double-layer thermal knitted underwear as the research object, uses a warm body sweating dummy, measures its thermal resistance and moisture resistance, and uses a three-dimensional body scanner to measure the volume of the air layer on the surface of the underwear and the dummy. Through the measurement, the influence of the thickness of the air layer between the thermal underwear and the human body on its thermal comfort can be explored.

1 Experimental program

1.1 Measuring clothing

In this study, 4 men's double-layer thermal knitted underwear with sizes M, L, XL, and XXL were selected for measurement. Among them, the M, L, XL and XXL sizes correspond to tight-fitting, fit-fitting, looser, and loose-fitting, respectively. The 4 pieces of underwear are round neck and long sleeves, and with the increase of size, the indexes of bust, waist, and shoulder width increase evenly, but the indexes of clothing length, sleeve length and neck circumference remain the same.

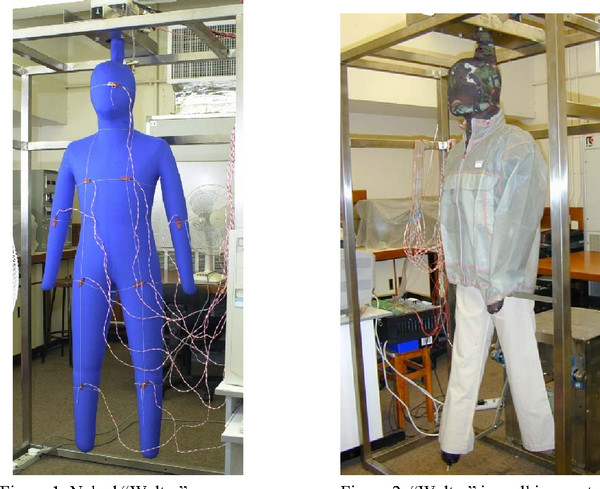

1.2 Sweating Fabric Manikin (Walter)

In this study, the standing warm body sweating dummy Walter was used to measure the thermal resistance and moisture resistance of thermal underwear. During the measurement, the dummy wore different sizes of thermal underwear on the upper body, and the same tight-fitting knitted trousers on the lower body.

1.3 Three-dimensional human body scanner

The three-dimensional body scanner VITUS was used for this body measurement. According to the standard ISO20685:2005, it is calibrated before measurement. The human body measurement is carried out in a temperature environment of (25 ± 2) ℃. When scanning the human body, the head of the dummy is fixed and the feet are off the ground. During scanning, the naked dummy is measured first to obtain the volume of the dummy when it is naked, and then the dummy wearing different sizes of underwear is measured to obtain the volume of the dummy wearing the underwear. In order to ensure the reliability of the measurement data, the measurement of each state is performed 3 scans from 3 different angles of the dummy.

1.4 Determination of thermal resistance, moisture resistance and moisture permeability index Thermal resistance can be obtained according to the standard ASTM 1291-10, and its calculation formula is shown in formula (1).

2 Results and discussion

2.1 Thermal resistance and moisture resistance measurement results

It can be seen that in the range of the measured size of the thermal underwear, the overall thermal resistance first increases and then decreases with the increase of the size. When the size is increased to XL, the thermal resistance is the largest, indicating that the underwear has the best thermal performance at this time. This is because as the size of the underwear increases, the volume of the air layer between the underwear and the dummy is also increasing. Due to the higher thermal resistance of still air, the thermal resistance of the underwear also gradually increases. However, as the volume of the air layer further increases, the heat loss caused by air convection begins to increase, so the thermal resistance will gradually decrease. It can be seen from Table 3 that within the range of the measured size, the moisture resistance of thermal underwear gradually increases with the increase of the size of the underwear, and when the size increases from M to L, the increase is more obvious, but from L When the number reaches the XXL number, the increase is relatively slow, and the increase rate gradually decreases. This is related to the fiber composition of thermal underwear, which is made of 100% pure cotton fiber, which has good moisture absorption, and the absorbed water is not easily lost to the air, so the moisture resistance is also large.

2.2 Moisture permeability index of heating underwear

In order to further analyze the influence of the air layer volume on the thermal resistance of thermal underwear, a polynomial regression model (R2 = 0.99, p <0.05) between the air layer volume and the thermal resistance between the underwear and the dummy was established, where y is the underwear’s thermal resistance. The overall thermal resistance, x is the volume of the air layer between the underwear and the dummy. It can be seen from the regression model that the thermal resistance of thermal underwear gradually increases within a certain range of air layer volume. When the thermal resistance reaches a certain value, it will gradually decrease as the air layer volume increases.

2.3 The relationship between air layer volume and moisture resistance

In order to further analyze the influence of air layer volume on the moisture resistance of thermal underwear, a polynomial regression model (R2 = 0.91, p <0.05) between air layer volume and moisture resistance was established. From the regression model, it can be seen that the moisture resistance of thermal underwear It gradually increases within a certain range of air layer volume, and when the moisture resistance reaches a certain value, it also gradually decreases as the air layer volume increases.

3 Conclusion

On the one hand, within the measured range, the thermal resistance of the thermal underwear first increases and then decreases with the increase of the air layer volume, while the moisture resistance gradually increases within the measured range. From the established regression model, the thermal resistance and moisture resistance both increase to their respective maximum values with the increase of the air layer volume, and then gradually decrease. On the other hand, the moisture permeability index of thermal underwear gradually decreases with the increase of underwear size within the range of the measured underwear size, indicating that its thermal comfort performance is gradually weakening. Based on this, this subject will further measure and evaluate the thermal comfort and aesthetics of thermal underwear to determine a suitable relaxation design that takes into account both thermal comfort and aesthetics of thermal underwear.

The above introduction about Sweating Fabric Manikin (Walter) is over. For more information, please leave us a message!

2022-01-06 11:05