Walter Sweating Fabric Manikin's high temperature protective clothing test

A high-temperature protective clothing test experimental system based on Walter Sweating Fabric Manikin, including a high-temperature cabin, the interior of the high-temperature cabin is suspended with Walter Sweating Fabric Manikin, and the high-temperature cabin is equipped with a hot exhaust system and a high-temperature radiant panel, a hot exhaust system and The high temperature radiation panels are connected to the control box for control. The Walter Sweating Fabric Manikin and surrounding detectors are connected to the dummy control system and data acquisition system. The dummy is put on protective clothing and heated for high temperature testing to simulate the thermal physiology of the human body. Process to make the test results closer to the real situation.

Firefighters and workers in special industries are often exposed to harsh environments with strong heat radiation and high temperatures, and the duration of time varies greatly. In strong radiation, high temperature work and emergency environments, high temperature protective clothing is widely used. The thermal insulation performance of protective clothing is directly related to the protective efficiency and personnel safety, and the wearing comfort and thermal comfort of the clothing will directly affect the rescue efficiency of firefighters and the production efficiency of work.

In recent years, my country has also issued some national regulations on the performance of protective clothing, such as GB/T 20097-2006 "General Requirements for Protective Clothing", GB 8965. 1-2009 "Flame Retardant Protection of Protective Clothing Part 1: Flame Retardant Clothing", GA633 -2006 "Firefighters Rescue Protective Clothing" etc. Internationally, the United States and the European Union have issued a series of standards that also stipulate the thermal insulation performance of protective clothing materials, and at the same time standardize the testing methods and standard procedures for protective performance. At present, there is still a lack of a unified understanding of how to measure the protective performance of protective clothing in China, and there is no mention of human factors such as wearing comfort. Therefore, it is necessary to develop a protective performance and comfort test device that can be promoted.

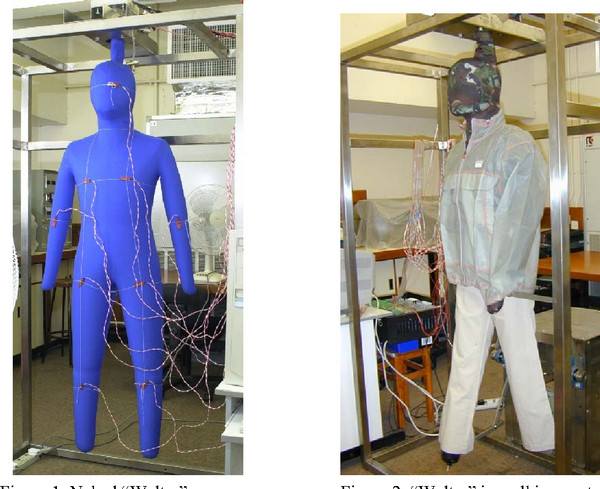

Traditional protective clothing testing methods mainly use heating plates to test the thermal insulation performance of the protective clothing textile materials. Since it cannot simulate the real dressing state, it cannot meet the test requirements for accurately and truly evaluating the wartime performance of the protective clothing when the human body is actually worn. . In high-temperature environments such as fires, to study the thermal response of the human body, or to carry out the test of human clothing, the Walter Sweating Fabric Manikin has become a viable tool due to the danger of the experimental environment.

Since the beginning of the 1940s, Walter Sweating Fabric Manikin has been developed by leaps and bounds as a biophysical test equipment that can simulate the heat and moisture exchange between the human body and the environment. Its body and physical parameters are similar to those of ordinary adults. The body is generally made of metal materials or metal composite materials. It uses internal heating, internal surface heating and external surface heating to simulate the body temperature of the human body or simulate the metabolic heating of the human body. Human equipment also has additional functions such as sweating and breathing, and is continuously used in research related to human comfort in the fields of clothing and environment.

Therefore, the establishment of a test device with Walter Sweating Fabric Manikin as the core to carry out performance testing of protective clothing in a high-temperature environment that simulates disasters is of great significance to meet my country's urgent needs for performance testing and experimental research of protective clothing.

In order to overcome the above-mentioned shortcomings and deficiencies in capabilities of the prior art, the purpose of this utility model is to provide a high-temperature protective clothing test experimental system based on Walter Sweating Fabric Manikin, creating a controllable indoor high-temperature environment, using Walter Sweating Fabric Manikin It simulates the thermal interaction process between the human body in the high-temperature indoor environment and the environment and the thermal physiological adjustment process of the human body, so that the dummy wears a protective moon, which meets the research needs of accurately testing the performance of protective clothing according to different experimental conditions.

In order to achieve the above-mentioned purpose, the technical solution of the present invention is realized as follows: A high-temperature protective clothing test experimental system based on Walter Sweating Fabric Manikin includes a high-temperature cabin 1. The interior of the high-temperature cabin 1 is suspended with Walter Sweating Fabric Manikin 2. The cabin 1 is equipped with a hot exhaust system 3 and a high-temperature radiant panel 4. The hot exhaust system 3 and the high-temperature radiant panel 4 are all connected to the control box 5 for control, and the Walter Sweating Fabric Manikin 2 and the surrounding detectors 11 are controlled by a dummy The system is connected to the data acquisition system 6.

The high-temperature cabin 1 is constructed from high-temperature resistant plates 7 into a space-based support structure. The high-temperature radiant panel 4 is placed vertically in the high-temperature cabin 1, and a detachable radiant partition is provided between the high-temperature radiant panel 4 and the Walter Sweating Fabric Manikin 2. Board 8.

The utility model uses the Walter Sweating Fabric Manikin, which is more advanced than the existing testing equipment, to simulate the thermal physiological process of the human body. Compared with the existing clothing testing system, the utility model has obvious advantages:

(1) Using Walter Sweating Fabric Manikin as a human body simulation device, it can simulate physiological activities that maintain a constant body temperature, as well as the sweating of the human body, with higher simulation and more real and accurate testing.

(2) Using Walter Sweating Fabric Manikin as the test equipment, the space structure is closer to the actual situation of human body wear, making the test results closer to the real situation.

2022-01-05 14:34