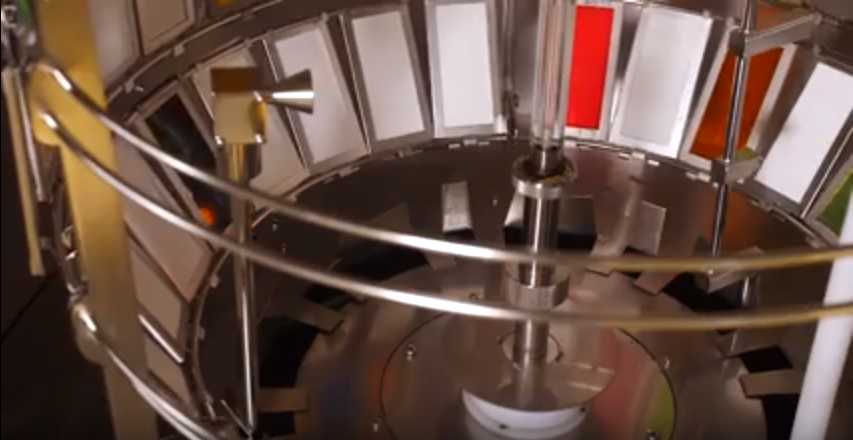

Xenon Test Chamber/weather ometer

Introduction

Weather-Ometer and Fade-Ometer tester adopts water-cooled xenon lamp. This instrument using argon arc lamp simulation control ideal natural climate and solar and other experimental conditions to to test the color and performance of textile dyes. It can also test the material Anti-aging properties, which can ensure good reproducibility and reproducibility on the basis of accurate test product life. Besides, it is widely used in plastics, paint coating, ink, packaging, automotive materials, photochemical materials, pigment dyes and textiles and other industries. The equipment has been certified by several international standards organizations.

Applications

Weather-Ometer and Fade-Ometer with their advanced digital control systems, represent monumental achievements in applying digital and optical technologies in easy-to-use laboratory weathering instruments. The Series is approved by many OEMs in the textiles, paints & coatings and plastics industries as the exclusive platform to deliver accurate, reproducible and repeatable results for predicting service life. The Series has been certified CE, UL, CSA, ISO and EN compliant

Weather-Ometer and Fade-Ometer tester adopts water-cooled xenon lamp. This instrument using argon arc lamp simulation control ideal natural climate and solar and other experimental conditions to to test the color and performance of textile dyes. It can also test the material Anti-aging properties, which can ensure good reproducibility and reproducibility on the basis of accurate test product life. Besides, it is widely used in plastics, paint coating, ink, packaging, automotive materials, photochemical materials, pigment dyes and textiles and other industries. The equipment has been certified by several international standards organizations.

Applications

Weather-Ometer and Fade-Ometer with their advanced digital control systems, represent monumental achievements in applying digital and optical technologies in easy-to-use laboratory weathering instruments. The Series is approved by many OEMs in the textiles, paints & coatings and plastics industries as the exclusive platform to deliver accurate, reproducible and repeatable results for predicting service life. The Series has been certified CE, UL, CSA, ISO and EN compliant

Features

◆ Xenon Lamp Cooling System-The Series is equipped with a new,ground-breaking xenon lamp cooling system that dramatically reduces the amount of cooling water used.

◆ Rotating Sample Rack-Rotating rack delivers the best exposure uniformity

◆ Control system - Enhanced control system can handle complex custom programs and simple preprogrammed test, and simple operation page icon is clear and easy to understand ; Irradiation, temperature, humidity programmable step by step change, to meet the various user test requirements.

◆ Intelligent and friendly operating system - intuitive LCD touch interface, full-featured, a variety of languages can be selected; water purity indicator can monitor the input water quality; SmartLight MonitorTM ensures that the lamp is installed correctly.

◆ Irradiance closed-loop monitoring and automatic adjustment, can be calibrated by the irradiance calibration device on a regular basis. Radiation calibration device should be CNAS / A2LA / JAB and other international mutual recognition agency certificate. The calibration mechanism of the calibration device shall be certified by ISO 17025.

Standards

ISO 105-B04 Textiles - Tests for colour fastness - Part B04: Colour fastness to weathering: Xenon arc test

ISO 105-B06 Textiles - Tests for colour fastness - Part B06: Colour fastness and ageing to artificial light at high temperatures: Xenon arc fading lamp test

ISO 105-B10 new standardTextiles - Tests for colour fastness - Part B10: Artificial weathering - Exposure to filtered xenon-arc radiation

ISO 12040 Graphic technology - Prints and printing inks - Assessment of light fastness using filtered xenon arc light

ISO 16474-2 Paints and varnishes - Methods of exposure to laboratory light sources - Part 2: Xenon-arc lamps

ISO 3917 Road vehicles - Safety glazing materials - Test methods for resistance to radiation, high temperature, humidity, fire and simulated weathering

ISO 4892-1 Plastics - Methods of exposure to laboratory light sources - Part 1: General guidance

ISO 4892-2 Plastics - Methods of exposure to laboratory light sources - Part 2: Xenon-arc sources

Technical Parameters

◆ Xenon Lamp Cooling System-The Series is equipped with a new,ground-breaking xenon lamp cooling system that dramatically reduces the amount of cooling water used.

◆ Rotating Sample Rack-Rotating rack delivers the best exposure uniformity

◆ Control system - Enhanced control system can handle complex custom programs and simple preprogrammed test, and simple operation page icon is clear and easy to understand ; Irradiation, temperature, humidity programmable step by step change, to meet the various user test requirements.

◆ Intelligent and friendly operating system - intuitive LCD touch interface, full-featured, a variety of languages can be selected; water purity indicator can monitor the input water quality; SmartLight MonitorTM ensures that the lamp is installed correctly.

◆ Irradiance closed-loop monitoring and automatic adjustment, can be calibrated by the irradiance calibration device on a regular basis. Radiation calibration device should be CNAS / A2LA / JAB and other international mutual recognition agency certificate. The calibration mechanism of the calibration device shall be certified by ISO 17025.

Standards

ISO 105-B04 Textiles - Tests for colour fastness - Part B04: Colour fastness to weathering: Xenon arc test

ISO 105-B06 Textiles - Tests for colour fastness - Part B06: Colour fastness and ageing to artificial light at high temperatures: Xenon arc fading lamp test

ISO 105-B10 new standardTextiles - Tests for colour fastness - Part B10: Artificial weathering - Exposure to filtered xenon-arc radiation

ISO 12040 Graphic technology - Prints and printing inks - Assessment of light fastness using filtered xenon arc light

ISO 16474-2 Paints and varnishes - Methods of exposure to laboratory light sources - Part 2: Xenon-arc lamps

ISO 3917 Road vehicles - Safety glazing materials - Test methods for resistance to radiation, high temperature, humidity, fire and simulated weathering

ISO 4892-1 Plastics - Methods of exposure to laboratory light sources - Part 1: General guidance

ISO 4892-2 Plastics - Methods of exposure to laboratory light sources - Part 2: Xenon-arc sources

Technical Parameters

| Items | Parameters |

| Light source | 4500 W water-cooled xenon arc lamp |

| Xenon lamp life | More than 1000 hours. The spectral energy distribution curve was stable after 300 hours |

| Filter | Internal and external filters (daylight filter, window glass filter, UV extension filter) can be replaceable |

| Irradiance control | 340/420 or 300-400nm select single point automatic control, optional second point monitoring |

| Lighting monitoring | Intelligent light monitoring |

| Relative humidity control | Automatic |

| Humidity range | Drying cycle Humidity: 20-80 ± 5% RH, wetting cycle Humidity: 95 ± 5% |

| Temperature control | Automatic Test chamber temperature control: 20-65 ± 2 ℃ |

| Temperature |

Black Standard Temperature (BST) :50~100±2℃ Black Panel Temperature (BPT) :45~90±2℃ |

| Simultaneous control BPT or BST and chamber temperature | Standard |

| BPT/BST double control | Optional |

| Specimen frame type | Monolayer |

| Exposure test area | 2188cm2(339in2) |

| Power supply | 400/230V, 3phase, 4 wire, 50Hz, 38 A |

| HVAC-MJ/h (BTU/h) (maximum) | 26.06MJ/h (24703BTU/h, 275CFM) |

| Compressed air | 0.11m3/min (Max 4CFM), @552kPa, (80psi) |

| Water flow | Pressure: 38-345kPa (20-50psi) |

| Humidification: deionized water 0.12l / min | |

| Sample spray: deionized water 0.07l / min | |

| Sample rack spray: deionized water 0.07l / min | |

| Dimension | (L x W x H):95cm x 84cm x 183cm |

| Base | 115cm x 240cm |

| Weight | 404kg (890lb) |

| Daylight filter and UV extension filter @ 340 setting range | ≥0.51W/m |

| Window glass filter @ 420nm setting range | ≥1.1W/m |

| Irradiance control deviation | ±0.01W/m2 |

| @Tuv (300nm-400nm) between the average irradiance |

More than 120W / m2 The irradiance E at any point on the surface of the specimen does not exceed ± 10% of the average of the irradiance on the entire surface. |

| Radiation exposure area | ≥3000cm2 Also accommodate specimen number ≥50 |

| Specimen size | Between 50*100mm and 70*150mm |

| Test area height (flat) | ≥30cm |

| Single automatic cycle test time setting upper limit | ≥2000 hours |

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price