Surgical Face masks are typically used by surgeons to protect their patients from their mouth-borne germs—but“those masks don't work to prevent inhaling diseases.The masks,which cover the nose and mouth,are often made from a flimsy material and aren’t fitted to the face.In other words,spaces and gaps can form around the cheeks and edges of the mouth,making it easy for air to move in and out.

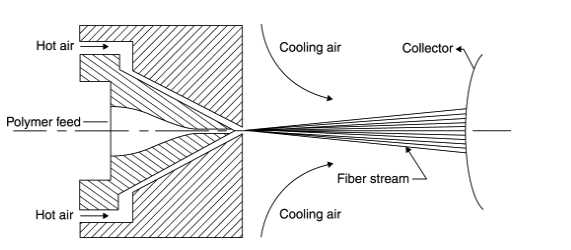

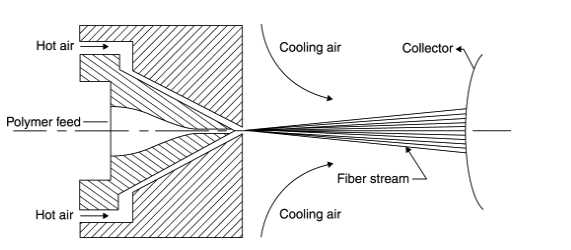

This 3 ply material is made up from a melt-blown material placed between non-woven fabric.The melt-blown material acts as the filter that stops microbes from entering or exiting the mask.Most surgical masks feature pleats or folds.Commonly,3 pleats are used allowing the user to expand the mask so it covers the area from the nose to the chin.There are 3 different ways to secure the masks.The most popular is the ear loop,where a string like material is attached to the mask and placed behind the ears.The other is the tie-on and the head band.The tie-on straps consist of four non-woven straps that are tied behind the head.

As for the production of face masks,there are two kinds of machines for Surgical Face masks.one is the Face Mask Production Line.the other is test machines for quality control.Full-automatic mask production line is with fine workmanship,stable performance and high production efficiency.The disposable mask production line adopts a“one drag two”design,that is,a mask forming machine,two ear band welding machines(outer ear bands)are connected through a one-to-two transmission line.it can realize the full-automatic production process from coil feeding,folding and pressing,and slitting,ear band feeding,welding,and unloading.

Test machine for quality control includes different test machines for test different items which depends on the test standard you must conform to.just like EN 14683:2014.The instruments to test the face mask as per EN 14683:2014“Medical face masks.Requirements and test methods

The test which you should done it as per EN 14683:2014 are:

1-The ability of medical masks to resist BFE(bacterial filtration efficiency).

2-The ability of medical masks to resist PFE(particulate filtration efficiency).

3-The ability of medical masks to prevent fluid leakage.

4-The ability of medical masks to resist flammability.

5-Ventilation pressure(pressure differential).