Continuous abrasion test & dry-sand wheel test

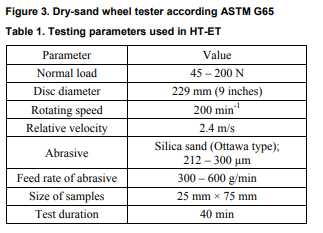

Abrasion tests with 3-body-abrasion condition under comparatively low stress can be carried out according to ASTM G65 [12] on a dry-sand rubber-wheel tester (see Figure 2). Different option or variants are used. Procedure A is a relatively severe test which will rank metallic materials on a wide volume loss scale from low to extreme abrasion resistance (Table1). It is particularly useful in ranking materials of medium to extreme abrasion resistance. Procedure B is a short-term variation of Procedure A for less resistant materials whereas Procedure C is a short-term variation of Procedure A to be used for thin coatings.

Rotation speed and normal load are kept constant (for Procedure A at 200 min-1 and 130 N respectively) over a sliding distance of 4309 m. Ottawa silica sand at grain size of 212 – 300 ?m is used as abrasive. Abrasion test results are reported as volume loss in cubic millimetres for the particular test procedure specified.

Modifications of the G65 tests consider additionalfeatures, e.g. to run the test specimen (especially cemented carbides) in a wet slurry condition with a 6.65 inch steel wheel according ASTM B-611.

Similarly, tests with the slurry modification and special 7-inch rubber wheels can be performed as described in ASTM G-105 [14]. Such methods are especially used to determine the resistance to abrasive wear of ferrous materials for applications involving slurry abrasive media (e.g. tilling soils and earth moving,) but can also be seen as “Recommended Practice for Determining Resistance to Abrasive Wear of ferrous metals using Rubber Wheel Abrasion Machine”, recommended by the Society of Automotive Engineers.

2018-11-28 15:24