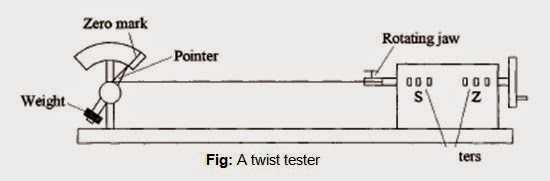

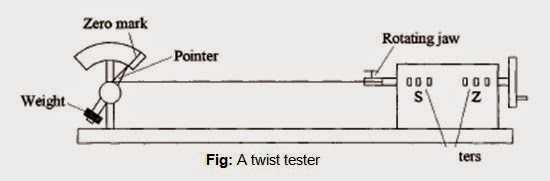

Twist Test methods and procedures

The electric twist tester can determine the twist and twist irregularity of all kinds of yarns. The structure of some fabrics can be disassembled, and the twist direction and twist coefficient of the disassembled fabrics can be analyzed through the detection of this instrument, so that the fabric can be woven according to the disassembled technology. Through the tension mechanism of the yarn twist tester, the shrinkage rate and thread density of the fabric can be analyzed.

Experimental methods and procedures:

(1) basic parameter setting

1. Turn on the power switch, LCD display information parameters.

2. Parameter setting

A. Press the corresponding key on the keyboard according to the indicators to be set, the cursor appears and flashes, and modify the parameters at the cursor.The parameters include: instrument model, time fraction, test times, line density, test length, method setting, twist direction and twist number.

B. Move the cursor according to the address and modify the data accordingly.

C. enter the test according to the test.

3. Speed adjustment

In the reset state, press "log" button, the motor drives the right yarn holder, display RPM, rotating speed adjusting button can change speed, make it conform to the requirements of the standards, click the "reset" button to return to reset state; When the test point is in the dynamic state, rotate speed control and twist 2 to adjust the point motion speed.

4. About halfway out

Due to the power off protection function of the machine, press "speed measurement" and press "reset" when exiting. After a group of samples is finished, press "reset" directly.

5. On line with microcomputer

A. On-line in the instrument reset state on-line.

B. Operation according to the microcomputer "help" prompt.

2018-06-27 15:40