How long is the xenon lamp aging test equivalent to natural exposure?

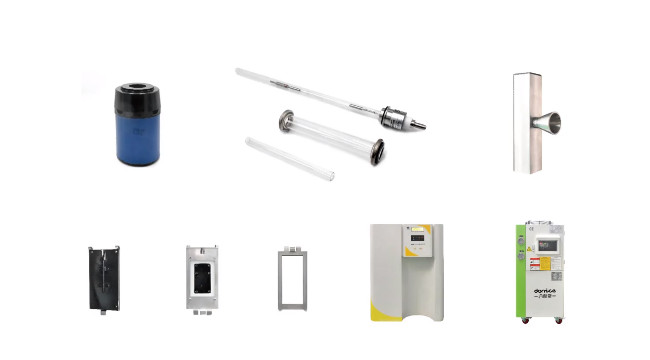

With the gradual reduction of the prices of Xenon lamp aging test chamber and UV Accelerated Weathering Tester and the gradual improvement of people's quality awareness, not only colleges and universities, scientific research institutes, and professional testing institutions are engaged in accelerated environmental aging test chambers, but now even ordinary enterprises They purchase and use accelerated aging test equipment in large quantities, such as: Xenon lamp aging test chamber, UV Accelerated Weathering Tester.

However, people have always hoped that the aging performance or aging resistance time of materials and products obtained in the laboratory can be used to calculate the weathering resistance time and performance of the materials or products under natural exposure.

Generally speaking, due to the different test conditions, different parameters, different equipment, as well as the inconsistency of the test objects, the huge difference in the exposure area and the climate of the use area, our conclusion is generally that we cannot infer and calculate, but now we The time equivalent to natural exposure is obtained through the fixed test conditions of the polyethylene cover bag for reference.

Of course, if the test object is changed, the conversion factor or acceleration factor will be different. With the popularization of polyethylene cover bags in freight and storage, the aging problem encountered in the use process has attracted more and more users and manufacturers' attention. In order to meet the needs of use, customers usually require that the cover bag can maintain a certain firm strength after being exposed to outdoor natural conditions for 12 months, and will not easily break under the action of external force. The "Haiyuan Dangerous Goods Rules" also clearly require that flexible bulk packaging should be sufficient to resist natural weather exposure due to ultraviolet rays, etc. The deterioration of polyethylene performance in outdoor exposure is caused by short-wave radiation in sunlight, and the absorption of solar energy by polyethylene can be effectively prevented by covering and shielding. In order to prevent or reduce photo-oxidative aging, stabilizers with light-shielding effect, such as carbon black or ultraviolet absorbers, can be added to polyethylene. However, it is often difficult for manufacturers to determine how much carbon black or UV absorber to add to meet customer requirements. The price of carbon black or ultraviolet absorber with covering and shielding effect on the market is generally tens of thousands of yuan per ton, and there are many kinds. There is still a lack of an effective method for what additives to add and how much to add to meet customer requirements. It is imperative to find an effective artificial accelerated aging test and calculation method to evaluate the aging resistance of polyethylene cover bags.

The experiment used a flat Xenon lamp aging test chamber and a daylight Q filter. A number of water-cooled xenon lamps are installed at the top of the Xenon lamp aging test chamber, and the filter is placed under the lamps. The top and sides of the chamber are equipped with reflector systems to enhance uniformity of irradiance. The test sample is placed on the sample tray under the lamp tube. The tray is tilted at a slight angle to facilitate the flow of water away. In order to obtain accurate and reproducible test results, the test chamber has a control system to control light intensity (irradiance), black mark temperature and relative humidity. Changes in light intensity can affect the rate of material damage, while changes in spectral energy distribution can affect the rate and type of material degradation.

The test standard adopts the most commonly used first cycle in ISO 4892-2 xenon arc lamp aging test method A, and the irradiance at the control wavelength of 340nm is 0.51±0.02 W•m. Every 120min is a cycle, including: drying 102min, spraying 18min. Control the temperature and relative humidity during drying: the black mark temperature is 65±3°C, the test room ambient temperature is 38±3°C, and the relative humidity is 50±10%.

Natural climate exposure is greatly constrained and influenced by objective conditions. For example, the exposure test site should be established under the actual use environment of the tested product; the site should be flat, open, free of water, and the grass height should not exceed 0.3m; There are no factory chimneys and facilities that emit a large amount of corrosive chemical gases near the site to avoid the impact of local serious pollution. The results of natural climate exposure will also vary with the different test seasons. However, this effect decreased with exposure time.

In order to use the Xenon lamp aging test chamber test data obtained in the laboratory to infer natural climatic exposure, it is necessary to determine the amount of solar radiation in each region and under different climatic conditions, as well as the correlation between the xenon lamp aging test and the natural climatic exposure of the actual use environment. To control the total amount of aging radiation of xenon lamp to be equivalent to the total amount of natural exposure radiation, it is necessary to consider the radiation intensity of its actual use environment. For example, if the origin of plastic products is located in Shandong Province, China, and the place of use is in Guangdong Province, China, the results of natural climate exposure in Shandong cannot be directly applied to Guangdong Province, and it needs to be converted and calculated according to the actual use environment of the product; if For plastic products produced in China to be exported to the United States, it is necessary to reasonably convert and calculate the artificial aging test results based on the local conditions in the United States.

According to the amount of solar radiation received, China can be roughly divided into five types of areas, and the United States can be roughly divided into four types of areas. The typical cities corresponding to the first, second, third, fourth and fifth regions in China are: Lhasa, northern Shanxi, Shandong, Guangdong and Sichuan. The typical cities corresponding to the A, B, C, and D regions in the United States are: Phoenix, Riverside, Dallas, Slackton. Every year in the world due to the aging of plastic products, product fading, loss of light, oxidation, cracking, powder The resulting direct or indirect economic losses are in the hundreds of millions of dollars. Through the xenon lamp aging test, combined with the annual average radiation of solar radiation in various places, and using statistical methods, the performance of polyethylene products equivalent to one year of natural climate exposure can be calculated in a relatively short period of time, effectively preventing production. and the waste of prolonged testing or natural climate exposure.

Artificial aging test time is long and the cost is high. Taking the xenon lamp aging test as an example, the filter should be scrapped after using 4000h, the outer filter should be scrapped after 2000h, and the inner filter can only be used for 400h. The method proposed in this paper can quickly apply the test results of relatively short time in the laboratory to actual use, and quickly obtain results with high confidence, which can greatly save the test cost, and significantly improve the process from product design and development to trial production. mass production efficiency. In the U.S. solar radiation class C area represented by Dallas, the material properties equivalent to one year (8760h) can be inferred in only 8l0h; in the U.S. solar radiation class D area represented by Slackton, only It takes 579h to infer material properties equivalent to one year.

QINSUN is a company specializing in the production of Xenon lamp aging test chamber. We always take: "Integrity is gold, service is guarantee, and quality is development" as our company's business purpose, and constantly improve and improve product quality and service to provide users with better A comprehensive overall solution for instrument applications, serving you with the spirit of daring to innovate and compete for the first place.

2022-02-07 14:58