Brief introduction to the development history and current situation of Sweating Fabric Manikin

Domestic research on Sweating Fabric Manikin started late. The Shanghai Fire Research Institute has trial-produced a similar Sweating Fabric Manikin, but due to the fact that the oil pan fire of the experimental device is greatly affected by the environment, the heat flux is unstable, the thermal contact area is uncertain, the power of the thermal radiation screen is insufficient, and the data acquisition and control system is soft. Issues such as hardware upgrades lead to defects in test accuracy and repeatability of results [18-19]. In addition, there are similar studies conducted by PLA-related institutions [16, 20]. In 2011, Donghua University built an internationally leading Sweating Fabric Manikin system—“Donghua Burning Man”, as shown in Figure 3.

Compared with other Sweating Fabric Manikin in various countries in the world, "Donghua Fire Man" not only meets ASTMF1930-2000 "Test Method for Evaluating the Flame Retardant Performance of Clothing under Booming Conditions with Dummies" and ISO13506-2008 "Insulation and Fireproof Clothing Complete Set of Clothing". In addition to the test method "Predicting Burns with Sweating Fabric Manikin", it also has the following unique features and leading technologies:

1) The dummy body simulates the characteristics of Chinese standard male body shape, and the influence of clothing composition and modeling specifications can be studied;

2) The neck, shoulder, elbow, wrist, hip, knee, ankle and other joints of the dummy simulate the range of activities of the corresponding parts of the human body, and can adjust and maintain actions and postures such as standing, sitting, running, and prostrate, so as to study the protection of clothing by human posture. the role of performance;

3) In addition to the torso of the dummy body, 135 high temperature sensors are evenly arranged on the surface of each body part such as the hands, feet, and head, which can be used to measure the thermal protection performance of clothing and thermal protective equipment such as breathing apparatus, helmets, gloves and protective boots. Tests alone or in combination;

4) Under the condition of a simulated fire field, the dummy can be automatically controlled at different speeds to carry out a dynamic simulation experiment of dressing to study the effect of exercise on the protection of human body burns.

Overseas Development Overview

In the 1940s, Baker and Smith designed the first Sweating Fabric Manikin for comparing the burning speed of shirts, but the dummy surface has no sensors and can only be used for qualitative research [12]. In 1962, the U.S. Navy used the instrumented Sweating Fabric Manikin for the first time to carry out the flame retardant test of clothing. The surface of the dummy was equipped with a heat flow sensor and a melting point indicator, which achieved a major breakthrough in the combination of dummy testing and quantification [13].

In 1972, DuPont improved the dummy's test equipment and recording system and named it Thermo-man [8]. The dummy is 185cm tall, with 122 heat flow sensors installed on the body surface. The experiment uses multiple butane gas burners to simulate various sudden combustion flames. The computer controls the experimental process, records the experimental data, analyzes the experimental results statistically, and reports that the two The percentage of body surface area of first- and third-degree burns to the total body surface area [14].

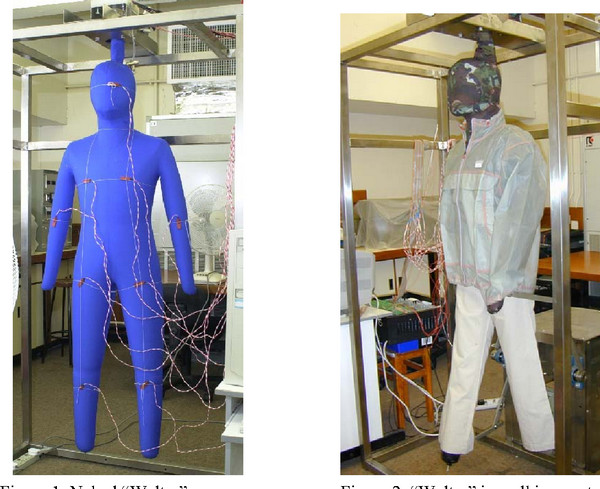

Subsequently, based on the working principle of Thermo-man, Sweating Fabric Manikin developed by various national research institutions has also come out one after another, such as Pyroman (as shown in Figure 2) of the Textile and Apparel Research Center of North Carolina State University in the United States and developed by the University of Alberta in Canada. dummy. There are 122 sensors on the surface of the Pyroman and 8 burners are mounted around it [8].

The Sweating Fabric Manikin at the University of Alberta is equipped with 110 heat flow sensors on the surface and 6 burners are installed around it [15]. All experiments use propane gas. After the burner is ignited, the flame generated by the propane gas can completely engulf the dummy. The computer controls the experimental process, obtains data, and gives burn reports [8, 15]. In addition, the United Kingdom, Switzerland, South Korea, Japan and other countries have also successively developed the Sweating Fabric Manikin test device [16].

In addition to the full-body Sweating Fabric Manikin, DuPont has also developed Thermoleg, which is similar in nature to Thermo-man, with movable leg mechanisms and simulating human running at a speed of 3-4m/s. There are 4 propane burners around the Thermoleg, which can emit 84kW/㎡ of flash fire. The device can be used to evaluate the local protective performance of clothing under dynamic conditions [17].

2022-01-24 10:42