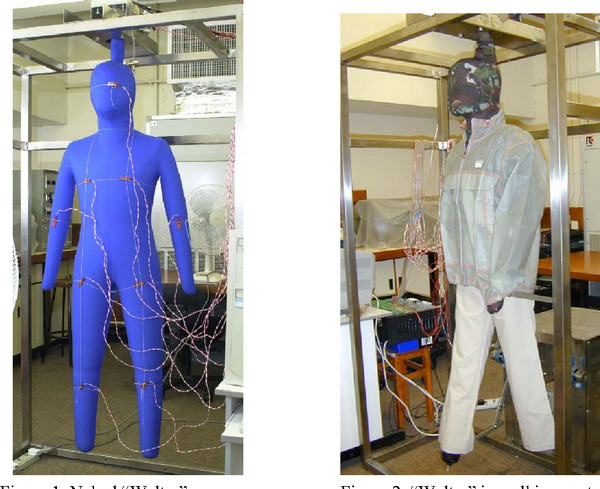

3 key design techniques of Sweating Fabric Manikin (Walter) thermostat control software

The key design technology of QINSUN Sweating Fabric Manikin (Walter) thermostatic control software is mainly the design of signal detection and dynamic connection library, real-time heat flow control, seamless connection between database and data binding control, and data management.

1.Signal detection and design of dynamic link library

The thermostatic control test system of the warm body first needs to collect the skin temperature and environmental parameters of the dummy in real time. Among them, the warm body skin temperature test point is 40 points, and the environmental parameter test point is 10 points. To achieve real-time and rapid acquisition of multipoint signals, this software uses the strong real-time characteristics of the VC language to design a real-time signal acquisition program and make it into a dynamic link library n1, so that the software system can give full play to the advanced data management functions of the VB language With the real-time characteristics of the VC language, it solves the problem of rapid acquisition of data signals.

2.Real-time heat flow control

Heat flow regulation is the key to realize the thermal resistance test of clothing and the simulation of the change process of human skin temperature by the thermostatic control equipment of the thermal manikin. When designing the heat flow control software, based on the basic model of the human body’s thermal response at low temperatures obtained from theoretical research, real-time acquisition, skin temperature signals, and the resistance of different heating sections of the dummy body, the real-time supply required to heat the dummy and maintain a dynamic thermal equilibrium state is calculated. The heat flow and the corresponding voltage value start the D/A converter to realize the closed-loop real-time regulation of heat flow.

3.Seamless connection of database and data binding control. Because the thermostatic control test system of the manikin needs to collect and process a large amount of raw data in real time, in the software design, the Data control provided by VB language is selected to collect and calculate the results in real time. Designed into different forms of the database, using its Updata, Refresh and other methods to update and operate the database, at the same time, select the label control, set its Datasource and Datafield attributes to seamlessly connect with the Data control, and successfully realize the real-time access of the database.

The QINSUNSweating Fabric Manikin (Walter) constant temperature control test software needs to realize real-time data collection, heat flow control, real-time modification of experimental process parameters, calculation, display, printing of test indicators, and selection of different test formats. This system software is designed Commonly used basic control objects such as timers, labels, picture boxes, scroll bars, buttons, dialog boxes, etc. are compiled, application codes are compiled to realize the time-sharing processing and sharing of data; and different forms are designed and produced to create a friendly The user interface provides good visibility and reliability of the entire software system.

2021-12-31 13:54