How to choose AFC-133 Filter Material Test Bench?

It has been more than a year since the outbreak of pneumonia in COVID-19. In this year, all countries in the world are actively fighting against this century-old human catastrophe. Facing the virus, how to protect medical staff and avoid more people from infection has become a difficult problem. Mask has become a hot word in 2020.

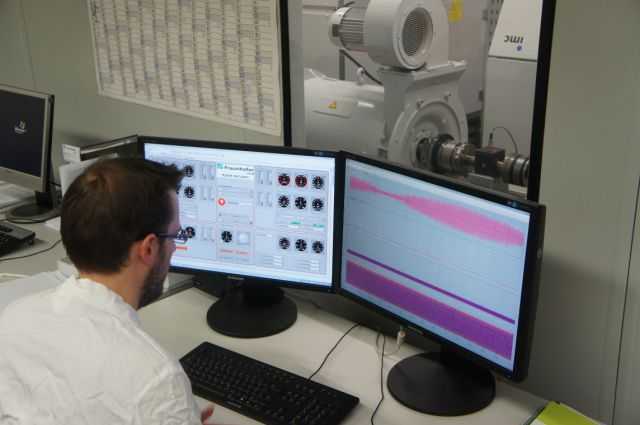

The demand for masks is in short supply, so many mask manufacturers start to operate without interruption for 7*24 hours. The Air filtration material test bench is an indispensable equipment in the production of masks, and it is also one of the popular products of Qinusn 2020.

How to choose Filter test bench?

First of all, make clear the standards you need. All test equipments are designed according to standards, so when you are looking for the Air filtration material test bench, you must first find out what standards you need to test.

Qinsun ISO11057/ASTMD6830/VDI/DIN3926/JIS8909-1Filter material performance tester

Introduction

Filter material test bench is designed and manufactured based on the exploration and experiments on the technological process with reference of YY0469 -2004 and GB2626-2006.

At the same time it takes the reference of advanced designing concepts of international similar equipment, (such as the United States TSI company), and it is based on the "European standard EN1822-3: 1998, but appropriate for the test status in domestic related industry.

DEHS aerosol generator or NaCl aerosol generator or the atmospheric air to determine the resistance, flow, efficiency and other performances for a variety of filters, medical masks and labor protection products. The user-friendly design features simple operation and a wide range of application. It provides a complete data parameter to the sample instantly.

Functional test:

1) Test of counting filtration efficiency and grading filtration efficiency. This system integrates the above functions through aerosol particle size spectrometer with switching valve.

2) Filter efficiency by weight. The weight-based filtration efficiency of the test filter can be tested by measuring the weight gain of the end high-efficiency filter and the test filter material.

3) Dust capacity test. The dust capacity test can be carried out under a wide range of dust concentration and surface wind speed. During the test, the backwash system is triggered by the pressure difference of the filter, and the dust is allowed to return to zero. The flow rate and other test gas parameters (temperature and humidity) are also recorded.

2021-02-07 10:52