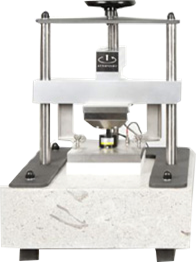

Heat Storage Performance Tester

Heat Storage Performance Tester provides standardized procedures and controls radiation heat conditions, providing repetitive measurement for heat storage and thermal transfer of protective fabric materials. Through measurement, the characteristics and rating of the material can be quickly identified, and the possibility of burn to the material is predicted through the integrated burn model of the instrument.

Operation Principle

The equipment is used to detect heat storage and thermal transfer characteristics of protective clothing, safety shoes, gloves, helmet and other materials, and determine the possibility that protective equipment can cause skin burns when exposed to heat.

Standards

ASTM F2731 Standard Test Method for Measuring the Transmitted and Stored Energy of Firefighter Protective Clothing Systems

Product Details

Instrument Structure:

The equipment includes radiant heat source, sample holder, calorimeter induction component, pneumatic start transfer tray with water-cooled slide frame, compressor, DAQ/control system and combustion injury analysis program.

Instrument Features:

· Assessing the possibility of skin burns which is related to the heat energy storage performance of fabric.

· Automatic or manual test operation

· Radiant plate heat source (adjustable temperature) generates radiation energy, which matches with the spectral line density of building fire.

· The water-cooled sample sliders, electronic driven, realizes the precise control of the time of exposure on the heat source.

· The pneumatic compressor uses a low conductivity core bar to apply a 1PSI load on the sample.

· The system includes the integrated burn model, which predicts the severity of skin injuries, and calculates the estimated time of exposure leading to secondary burns.

· The combustion results are real-time values and the graph shows the skin layer interface temperature and combustion synthesis of Omega.

System Including:

· Dell PC laptop.

· ThermDAC software with a combustion model

· Signal conditioning circuit and USB interface

· Power supply and control cable, operator manual

· One-year warranty.

Laboratory Requirement:

· The laboratory should be well ventilated with dry compressed air source and cooling water supply pipe.

· The desktop device is designed for operation of horizontal or vertical radiant heat sources.

· It is recommended to operate in a vertical direction.

Operation Principle

The equipment is used to detect heat storage and thermal transfer characteristics of protective clothing, safety shoes, gloves, helmet and other materials, and determine the possibility that protective equipment can cause skin burns when exposed to heat.

Standards

ASTM F2731 Standard Test Method for Measuring the Transmitted and Stored Energy of Firefighter Protective Clothing Systems

Product Details

Instrument Structure:

The equipment includes radiant heat source, sample holder, calorimeter induction component, pneumatic start transfer tray with water-cooled slide frame, compressor, DAQ/control system and combustion injury analysis program.

Instrument Features:

· Assessing the possibility of skin burns which is related to the heat energy storage performance of fabric.

· Automatic or manual test operation

· Radiant plate heat source (adjustable temperature) generates radiation energy, which matches with the spectral line density of building fire.

· The water-cooled sample sliders, electronic driven, realizes the precise control of the time of exposure on the heat source.

· The pneumatic compressor uses a low conductivity core bar to apply a 1PSI load on the sample.

· The system includes the integrated burn model, which predicts the severity of skin injuries, and calculates the estimated time of exposure leading to secondary burns.

· The combustion results are real-time values and the graph shows the skin layer interface temperature and combustion synthesis of Omega.

System Including:

· Dell PC laptop.

· ThermDAC software with a combustion model

· Signal conditioning circuit and USB interface

· Power supply and control cable, operator manual

· One-year warranty.

Laboratory Requirement:

· The laboratory should be well ventilated with dry compressed air source and cooling water supply pipe.

· The desktop device is designed for operation of horizontal or vertical radiant heat sources.

· It is recommended to operate in a vertical direction.

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price