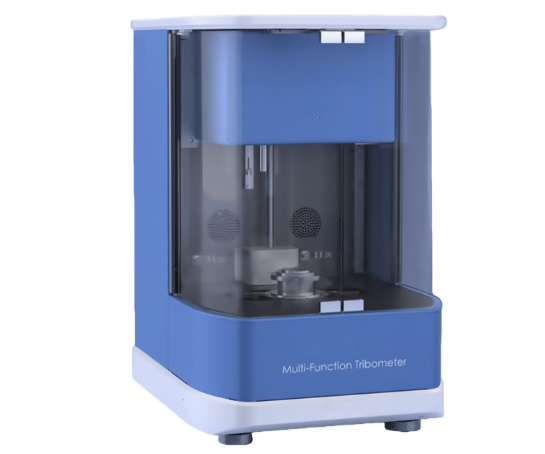

Compact Benchtop Multi Function Tribometer

Compact Benchtop Multi Function Tribometer is a compact, open-platform tribological testing system designed for the characterization of friction, wear, scratch, and related material properties. The instrument combines ease of use with fully automated test procedures and a multi-channel controller, ensuring high repeatability and precise measurements. With interchangeable force sensors and test modules, multiple tests—including scratch, friction, wear, and surface morphology measurement—can be performed on a single platform.

Application

The Compact Benchtop Friction and Wear Tester is suitable for a wide range of laboratory and industrial tribology applications, including:

Friction, wear, and scratch performance evaluation of metals, ceramics, polymers, coatings, and composite materials

Surface damage, indentation, and scratch resistance analysis

Fretting and linear reciprocating wear studies

Tribological behavior testing under high-temperature, low-temperature, vacuum, and corrosive conditions

Lubricant and additive performance evaluation using rotational and reciprocating test modes

Supported test configurations include ball-on-disk, pin-on-disk, high-speed reciprocating motion, and ring-on-block testing, with optional integration of 3D optical surface profiling.

Standards

The tester is designed to support test methods referenced in the following standards:

ASTM G99 (Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus)

ISO 20808 (Fine ceramics — Determination of friction and wear characteristics of monolithic ceramics by ball-on-disk method)

GB/T 3142 (Determination of load-carrying capacity of lubricants — Four-ball method)

SH/T 0189 (Test method for anti-wear properties of lubricating oils — Four-ball method)

Parameters

| Item | Description |

|---|---|

| Platform | Open-platform design for easy access and operation |

| Interchangeable Test Modules | Quickly replaceable modules enabling multiple tests on the same platform (rotational, reciprocating, etc.) |

| Force Sensors | High-resolution force sensors with multiple measurement ranges; maximum load up to 200 N |

| XY Stage | High-precision automated XY platform with automatic test radius adjustment; supports integration of 3D optical surface profiling |

| Maximum Temperature | Up to 1000 °C |

| XY Travel Range | 150 mm × 150 mm |

Features

Standard test configurations including ball-on-disk (pin-on-disk) and high-speed reciprocating motion

Loading range from mN up to 200 N, suitable for micro- to macro-scale tribological testing

Integrated 3D optical surface profiling capability

Closed-loop servo loading control for stable and repeatable measurements

High-temperature testing capability up to 1000 °C

Support for rotational, reciprocating, and ring-on-block test modes

Modular design with fast replacement of test modules

Fully automated XY positioning platform (150 mm × 150 mm)

Accessories

Ball-on-disk / pin-on-disk test module

High-speed reciprocating test module

Ring-on-block test module

Interchangeable force sensors

3D optical surface profiling module

Test Procedures

Select and install the appropriate test module according to the test requirement.

Mount the specimen and counter body securely on the test platform.

Set test parameters including load, speed, motion type, temperature, and test radius.

Perform system checks and sensor verification prior to testing.

Start the automated test sequence and monitor friction and load signals.

Complete the test based on predefined conditions or test duration.

Conduct surface morphology measurement and export test data for analysis.

Maintenance Information

Clean test modules, fixtures, and contact components after each test.

Regularly inspect and calibrate force sensors to maintain measurement accuracy.

Check mechanical components and motion stages periodically for smooth operation.

Maintain environmental and heating components according to usage conditions.

FAQ

1. What types of tests can be performed with the Compact Benchtop Friction and Wear Tester?

The Compact Benchtop Friction and Wear Tester is designed to perform multiple tribological tests on a single platform. Supported tests include friction and wear measurements using ball-on-disk or pin-on-disk configurations, high-speed linear reciprocating motion, scratch testing, and surface morphology analysis. The interchangeable module design allows quick switching between test modes without changing the base system, enabling efficient evaluation of different material behaviors.

2. What is the loading capability of this tester?

The tester supports a wide loading range from millinewtons up to 200 N through high-resolution force sensors with multiple measurement ranges. This capability allows testing of thin coatings and surface layers under low loads, as well as bulk materials and components under higher loads, ensuring flexibility for a variety of tribological applications.

3. Does the system support surface morphology measurement?

Yes. The system can integrate a 3D optical surface profiler, enabling direct measurement of wear tracks, scratches, and surface features. This integration allows correlation of friction and wear data with surface morphology, improving the accuracy and completeness of tribological analysis.

4. What motion modes are available for testing?

The tester supports rotational and linear reciprocating motion, as well as ring-on-block configurations through interchangeable modules. These motion modes enable simulation of sliding, rolling-sliding, and fretting conditions commonly encountered in real service environments.

Leave Message Get Price