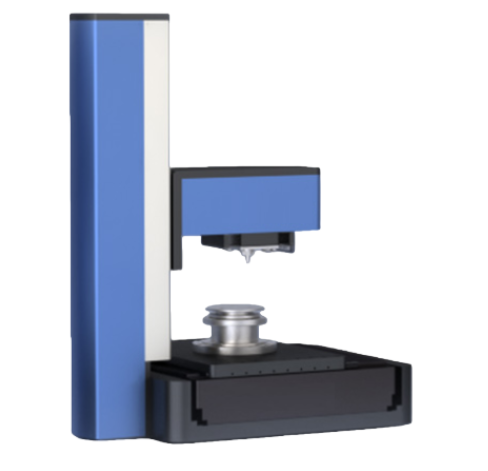

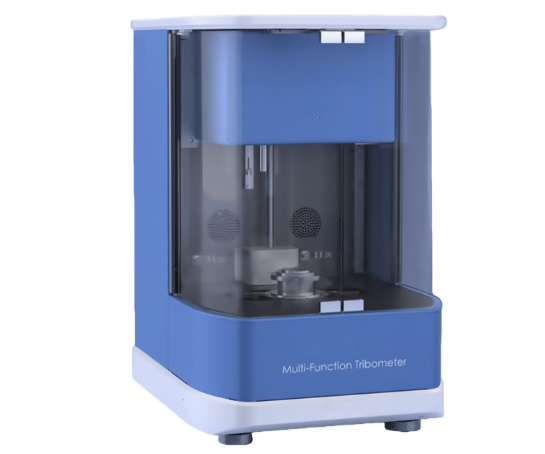

Benchtop Multi Function Tribometer

Benchtop Multi-Function Friction and Wear Tester is a compact yet highly precise tribological testing system designed for friction and wear measurements from nano-scale to macro-scale. The tester adopts a new-generation dual force sensor technology, enabling seamless force range switching from nN to macro loads without changing system configuration. With high resolution, excellent measurement accuracy, and compatibility with multiple environmental chambers, the system supports comprehensive tribological testing under various controlled conditions, making it suitable for both research laboratories and industrial applications.

Application

The Benchtop Multi-Function Friction and Wear Tester is designed for a wide range of tribological test scenarios, including:

Friction and wear evaluation of metals, ceramics, polymers, coatings, and composite materials

Performance assessment of lubricants, greases, additives, and extreme-pressure lubricants

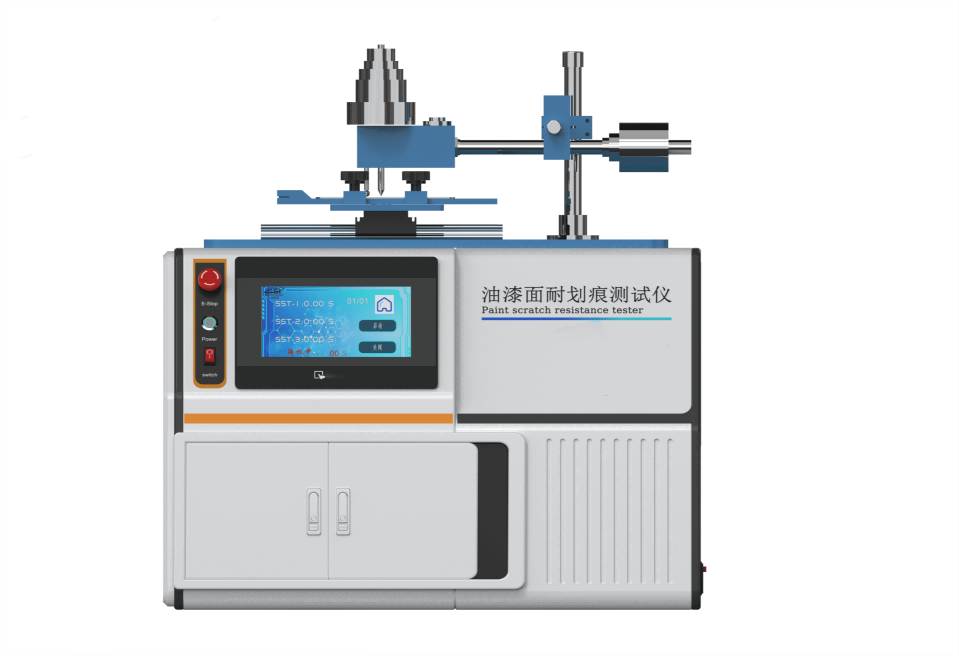

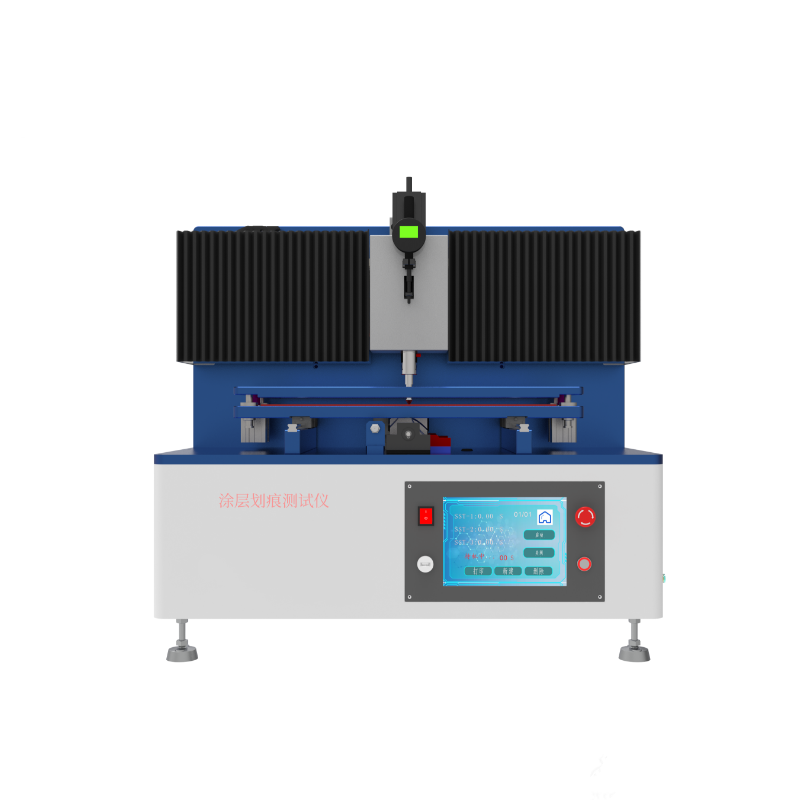

Scratch resistance, indentation behavior, and surface damage analysis

Fretting and linear reciprocating wear studies

Torque testing for tapping, twisting, and cutting tools

Tribological behavior analysis under high temperature, low temperature, vacuum, and corrosive environments

Supported test configurations include ball-on-disk, pin-on-disk, high-speed reciprocating motion, ring-on-block, and related modular test modes.

Standards

The tester is designed to support test methods referenced in the following standards:

ASTM G99 (Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus)

ISO 20808 (Fine ceramics — Determination of friction and wear characteristics of monolithic ceramics by ball-on-disk method)

GB/T 3142 (Determination of load-carrying capacity of lubricants — Four-ball method)

SH/T 0189 (Test method for anti-wear properties of lubricating oils — Four-ball method)

Parameters

| Item | Description |

|---|---|

| Platform Structure | Rigid structural design for stable and repeatable tribological testing |

| Environmental Control | Temperature: −50 °C to 1000 °C; Humidity: 5–95 % RH; optional corrosion and other environmental chambers |

| Interchangeable Test Modules | Quickly replaceable modules including rotational, reciprocating, and ring-on-block modules |

| Dual Force Sensor System | Two sensors can be installed simultaneously; force range from mN to 3000 N |

| X-axis Platform | High-precision automated X-stage with 150 mm travel for test module positioning |

| Data Acquisition & Motion Controller | High-speed, low-noise, multi-channel controller with fast feedback and data sampling rate up to 200 kHz |

Features

Standard test configurations including ball-on-disk (pin-on-disk), high-speed reciprocating motion, and ring-on-block

Wide loading capability from mN to 3000 N covering nano to macro tribological testing

New-generation dual force sensor technology enabling seamless force range switching

Closed-loop servo loading control for high stability and repeatability

Broad temperature testing capability from −60 °C to 1000 °C

Modular design with fast and easy module replacement

Fully automated X-axis positioning platform for efficient and repeatable testing

Accessories

Rotational test module (ball-on-disk / pin-on-disk)

High-speed reciprocating test module

Ring-on-block test module

Environmental chambers (temperature, humidity, corrosion)

Interchangeable force sensors

Test Procedures

Select the appropriate test module according to the required test method.

Install the test specimen and counter body securely on the platform.

Configure test parameters including load, speed, motion type, temperature, and environment.

Perform sensor verification and system calibration before testing.

Start the test and monitor friction force and normal load signals in real time.

Complete the test according to the predefined duration or wear criteria.

Export test data for analysis and reporting.

Maintenance Information

Clean test modules, fixtures, and contact components after each test.

Periodically calibrate force sensors and motion systems to maintain accuracy.

Inspect mechanical components and guide systems regularly to ensure smooth operation.

Maintain environmental chambers according to operating conditions and usage frequency.

FAQ

1. What force range can the Benchtop Multi-Function Friction and Wear Tester cover?

The tester supports a wide force range from millinewtons up to 3000 N using a dual force sensor system. Two sensors can be mounted simultaneously, allowing smooth switching between different load ranges without changing system configuration. This capability enables continuous testing from nano-scale surface interactions to macro-scale material and component wear, ensuring flexibility for diverse tribological applications.

2. What types of test motions are supported by this system?

The system supports multiple standard tribological motions through interchangeable modules, including rotational ball-on-disk or pin-on-disk testing, high-speed linear reciprocating motion, and ring-on-block configurations. These test modes allow evaluation of friction, wear, fretting behavior, scratch resistance, and surface damage under controlled conditions.

3. Can testing be performed under different environmental conditions?

Yes. The tester is compatible with multiple environmental chambers, enabling tests under temperatures ranging from −50 °C to 1000 °C and humidity levels from 5 % to 95 % RH. Optional corrosion chambers are also available, allowing tribological testing under simulated aggressive or service-specific environments.

4. How does the dual force sensor technology improve testing efficiency?

The dual force sensor technology allows two sensors with different measurement ranges to be installed at the same time. This eliminates the need for reconfiguration when switching between low-load and high-load tests, improving testing efficiency while maintaining high precision and resolution across the entire force range.

Leave Message Get Price