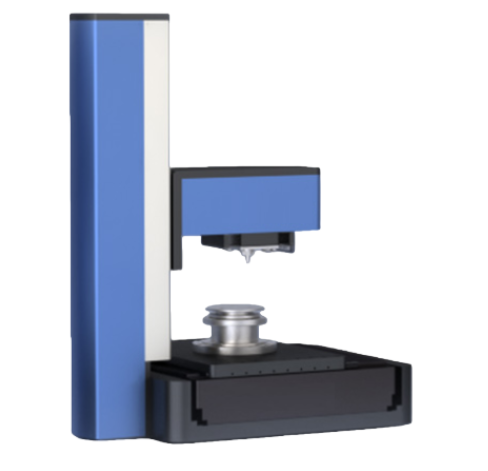

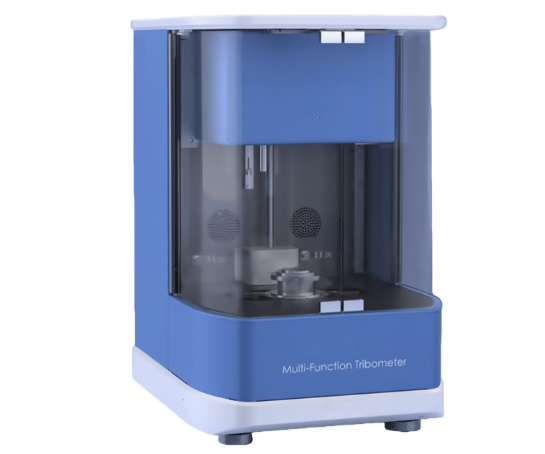

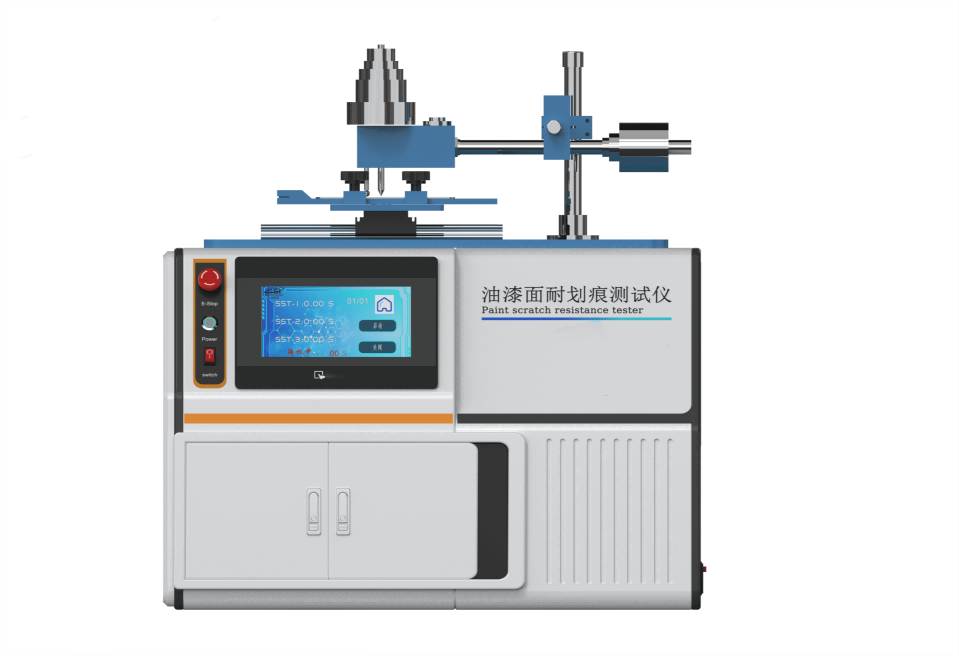

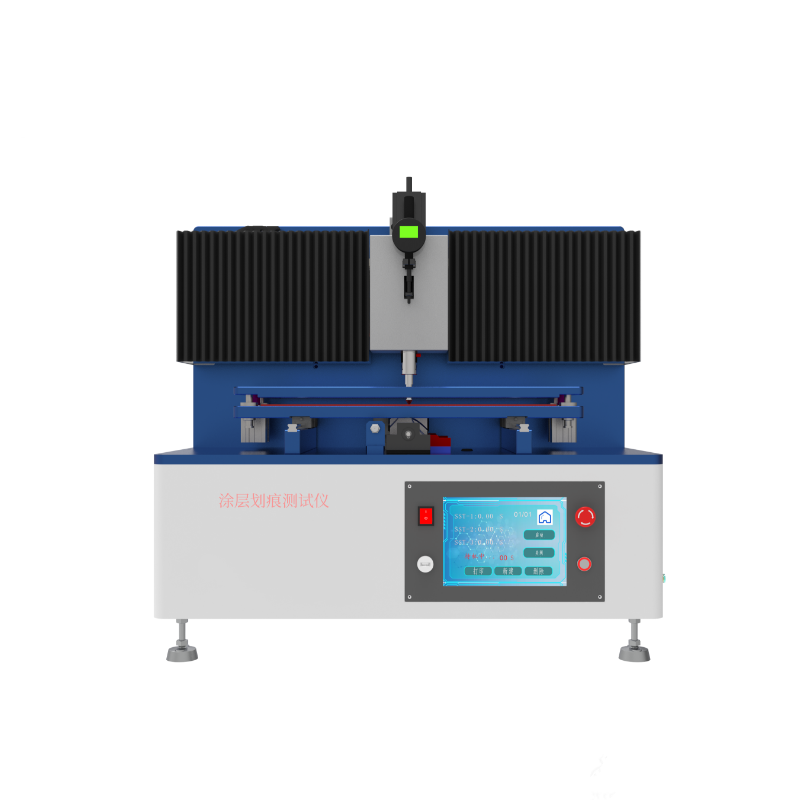

Surface Scratch Testing Machine

Surface Scratch Testing Machine is a laboratory testing device designed to evaluate the scratch resistance of printed circuit board and enclosure surfaces. Suitable for chemical, electronics/batteries, automotive and components, electrical, and other industries, it assesses material surface durability and mechanical strength through standardized scratch testing.

Application

- Durability testing of printed circuit board coatings;

- Scratch resistance testing of household appliance enclosures and similar surfaces;

Surface coating scratch resistance evaluation for electrical equipment and automotive components;

Surface durability testing for chemical and electronic materials.

Standards

GB 4943-2001 Part 1: Safety of Information Technology Equipment — General Requirements (Clause 2.10.6.6: Mechanical Strength / Drop / Housing Scratch Resistance)

GB 4706.1-2005 Part 1: Safety of Household and Similar Electrical Appliances — General Requirements (Clause 21.2: Mechanical Strength / Scratch Resistance of Enclosures)

Parameters

| Item | Technical Parameter |

|---|---|

| Steel Needle Head Vertex Angle | 40° |

| Steel Needle Tip Radius | 0.25 ± 0.02 mm |

| Steel Needle Indentation Force | 10 N ± 0.5 N |

| Moving Speed | 0 - 20 mm/s |

| Scratch Travel Range (X-axis) | 0 - 200 mm, adjustable |

| Scratch Spacing Range (Y-axis) | 0 - 200 mm, adjustable |

| Height Range (Z-axis) | 0 - 90 mm, adjustable |

| Steel Needle Scratch Angle | 80 - 85° |

| Sample Adjustment | 90° rotatable |

| Equipment Voltage | 220V 50Hz |

Features

Aluminum alloy frame with stainless steel end plates; test platform constructed from thickened aluminum plate;

PLC control system with stepper motor drive enables automatic X, Y, and Z-axis movement;

Text display allows configuration and visualization of test parameters;

Steel stylus precisely controls pressure and angle to ensure repeatability and accuracy in scratch testing;

Supports 90° sample rotation for multi-directional scratch testing.

Accessories

| No. | Accessory/Consumable | Quantity | Remarks |

|---|---|---|---|

| 1 | Steel Needle Head | 1 piece | Vertex angle 40°, tip radius R0.25 ± 0.02 mm |

| 2 | Load Weight | 1 set | Standard: 10N, other specifications optional |

| 3 | Sample Fixing Fixture | 1 set | Supports 90° rotation |

| 4 | Power Cable | 1 piece | Standard configuration |

| 5 | Tool Kit | 1 set | For steel needle installation and adjustment |

Test Principle

A steel stylus applies standardized pressure to the sample surface while moving along a predetermined trajectory, creating repeatable scratches to evaluate coating scratch resistance. Adjustable scratch pressure, angle, and speed simulate various standards and testing requirements.

Test Procedures

Operating Instructions:

Secure the sample on the test platform, ensuring it is flat and firmly fixed;

Adjust the steel needle pressure, angle, and height to ensure proper contact with the sample surface;

Set the scratch speed, stroke, and spacing;

Start the device; the steel needle automatically moves along the set trajectory to form scratches;

After completing the test, record the scratch condition and analyze the sample's scratch resistance;

Periodically inspect the steel needle and mechanical moving parts to ensure testing accuracy.

Experimental Procedure:

Mount the sample on the test platform and secure the fixture;

Set the scratch needle and load weights;

Select X, Y, and Z-axis travel and speed parameters;

Initiate the test program to automatically execute the scratching action;

Upon test completion, observe the scratch morphology and record results;

If repeat testing is required, adjust the sample position or parameters before rerunning.

FAQ

1. What materials can you test with this machine?

You can test printed circuit boards, plastic or metal enclosures, automotive components, coated electrical parts, and chemical or electronic material surfaces.

2. How is scratch pressure controlled?

Scratch pressure is applied through a calibrated steel needle with a constant load weight of 10 N ±0.5 N, adjustable for different testing requirements.

3. Can you perform multi-directional scratch testing?

Yes, the sample fixture allows 90° rotation, enabling testing in longitudinal and transverse directions.

4. How do you adjust the scratch trajectory and spacing?

You can configure X-axis travel for stroke length, Y-axis spacing, and Z-axis height via the PLC-controlled interface.

5. What is the recommended maintenance for the steel needle?

Regularly inspect for tip wear or deformation and replace the needle to maintain accurate and repeatable scratch results.

6. Can you test at different speeds?

Yes, the machine supports 0–20 mm/s scratching speed, which is adjustable to comply with multiple testing standards.

7. How do you ensure testing accuracy?

Ensure the sample is flat and securely fixed, the needle angle and pressure are correctly set, and the moving parts are clean and well-lubricated.

Leave Message Get Price