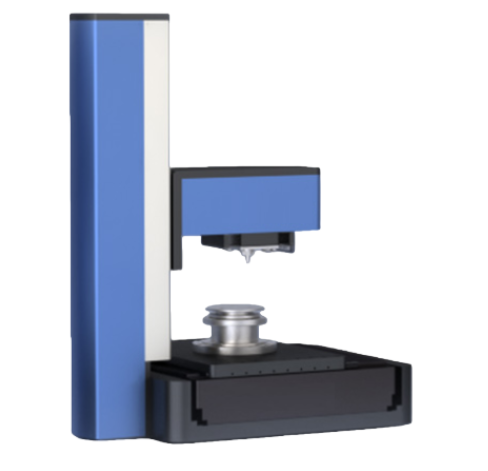

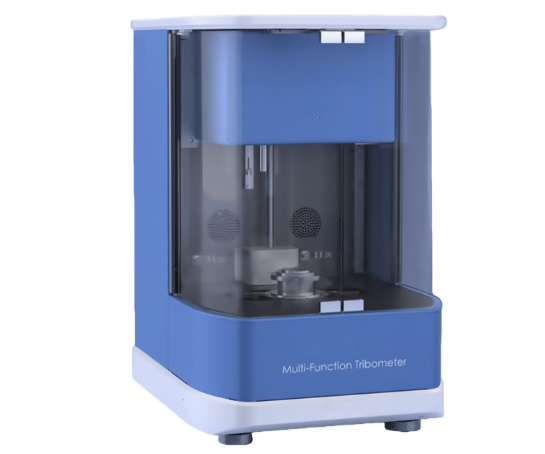

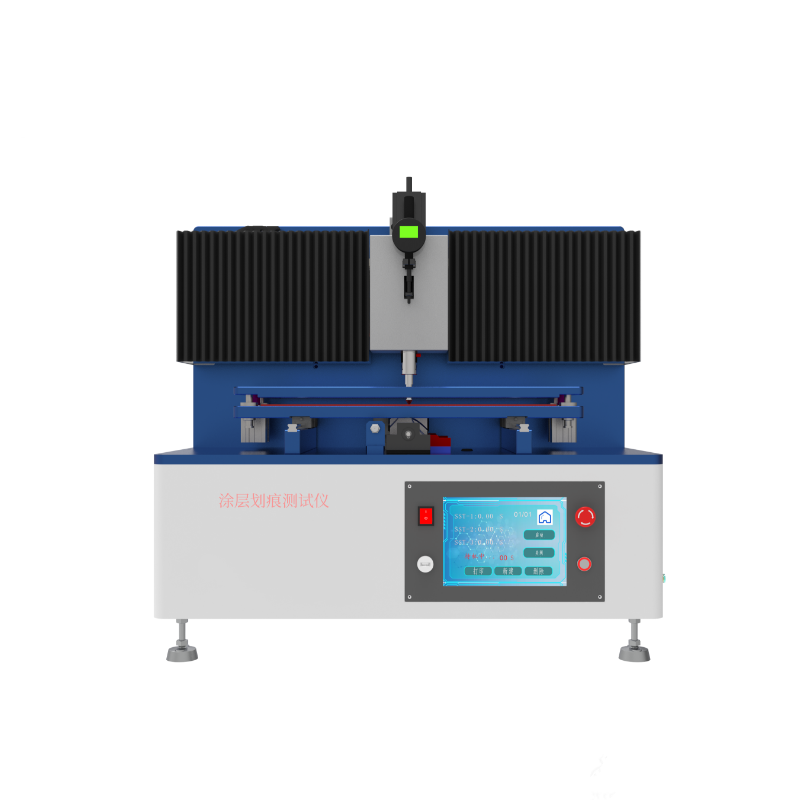

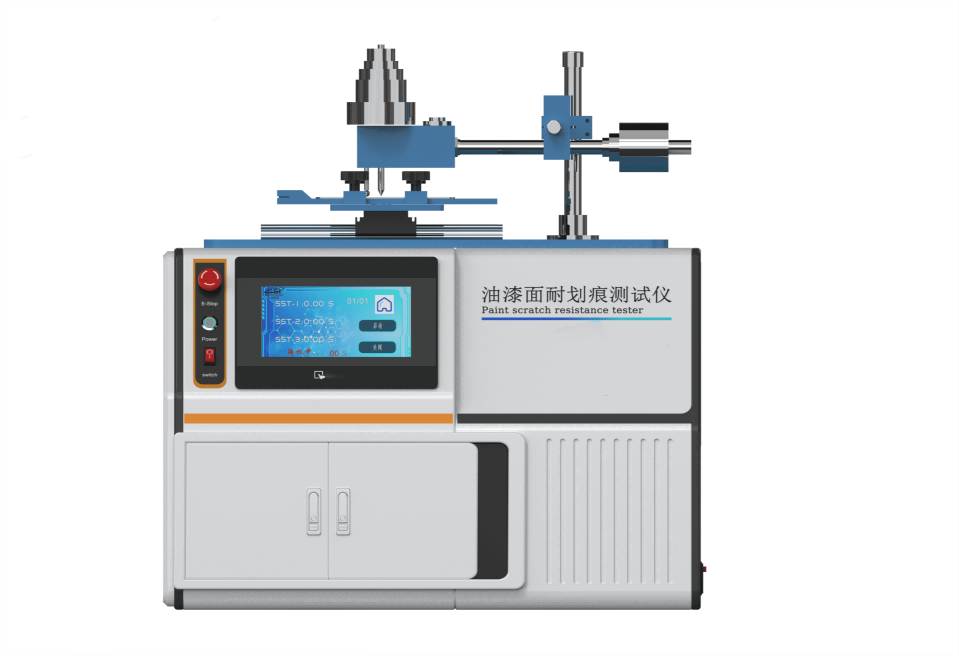

Paint Scratch Resistance Tester

Paint Surface Scratch Resistance Tester is a laboratory testing device used to evaluate the scratch resistance of paint films and coated surfaces. It is suitable for automotive surface coatings, metallic paints, coil coatings, ink coatings, and other material surfaces. By applying pressure through a controlled scratch needle, it creates repeatable scratches on the sample surface to determine the coating's scratch resistance.

Application

Road/rail/marine coatings;

Textile/printing surface coatings;

Aerospace coatings and materials;

Automotive and component surface coatings;

Comprehensive material surface scratch resistance testing.

Standards

ISO 1518 Paints and varnishes – Determination of scratch resistance

ASTM D5178 Test method for determining scratch resistance of coatings using a linear scratch apparatus

ASTM D2197 Test method for determining abrasion resistance of organic coatings

GB/T 23989‑2009 – Determination of scratch resistance of coatings

GB/T 1768-2006 – Test Method for Abrasion Resistance of Paint Films

GB/T 6739-2006 – Paints and Varnishes – Determination of Hardness of Paint Films by the Pencil Method

GB/T 9279-2007 – Paints and Varnishes – Cross-Hatch Adhesion Test

Parameters

| Item | Details |

|---|---|

| Input Voltage | 220V/50Hz |

| Control System | PLC + Touch Screen |

| Operation Interface | 7-inch color touch screen, Chinese/English switchable |

| Driving Method | Stepper motor drive |

| Scratching Speed | 0–25 mm/s, adjustable |

| Limited Stroke | 0–85 mm (other strokes available for free customization) |

| Test Times | 0–9999 times, presettable |

| Equipment Configuration | Automatic stop function after scratch contact (electrode device) |

| Contact Limit Angle | 18° |

| Contact Spherical Transition Size | R6 |

| Scratch Spacing | 0–50 mm, adjustable |

| Test Size | Approximately 150*100 mm range |

| Worktable | 360° rotatable |

| Scratching Pressure | Standard: 10N±0.5N, 1 piece; optional: 20N weight and 30N±0.5N scratching pressure |

| Scratching Head | R0.25±0.02 mm, other specifications optional |

| Dimensions | 380×300×180 mm (L×W×H) |

Features

PLC + touchscreen control with intuitive and user-friendly interface;

7-inch color touchscreen with Chinese/English language switching;

Stepper motor drive ensures smooth scratch motion;

Adjustable scratch pressure supports multiple test force values;

Customizable scratch needles adapt to different coating types;

Workbench rotates 360° for omnidirectional scratch testing;

Auto-stop function halts immediately upon contact, enhancing safety and accuracy;

Pre-set test cycles enable automated operation.

Accessories

| No. | Accessory/Consumable | Quantity | Remarks |

|---|---|---|---|

| 1 | Scratching Head | 1 piece | R0.25 ±0.02 mm, other specifications customizable |

| 2 | Weight | 3 pieces | Standard: 10N, optional: 20N, 30N |

| 3 | Worktable Fixing Fixture | 1 set | Suitable for samples of different sizes |

| 4 | Electrode Device | 1 set | Enables automatic stop after scratching |

| 5 | Power Cable | 1 piece | Standard configuration |

| 6 | Tool Kit | 1 set | For installation and adjustment of scratching needles and weights |

Test Principle

The paint scratch resistance tester applies controlled pressure via a scratch needle, guiding its tip along a preset trajectory to create repeatable scratches. By observing scratch morphology, length, and coating damage, the coating's scratch resistance can be quantitatively evaluated. Scratch pressure, speed, and spacing are adjustable to meet various standard requirements.

Test Procedures

Operating Instructions:

Secure the sample on the workbench, ensuring it is flat and firmly fixed;

Adjust the scratch needle and load weights to select the required pressure;

Set scratch speed, spacing, and travel distance;

Configure test cycles and automatic stop function;

Initiate the test, allowing the scratch needle to trace the programmed path across the sample surface;

Record and analyze scratch results upon test completion;

Periodically inspect the device's moving mechanisms and assess needle wear.

Test Procedure:

Mount the specimen on the rotating workbench, ensuring it is level;

Set scratch parameters: pressure, speed, spacing, stroke, and number of cycles;

Initiate the test and observe the scratch needle's movement across the specimen surface;

The test automatically stops after completing the preset number of cycles;

Inspect the scratches and record data for scratch resistance evaluation;

If repeat testing is required, adjust the specimen position or parameters and repeat the procedure.

FAQ

1. What types of coatings can you test with this instrument?

You can test automotive coatings, industrial paints, metallic coatings, coil coatings, ink layers, and other functional or decorative surface finishes.

2. How is scratching pressure controlled and adjusted?

Scratching pressure is controlled using calibrated weights, allowing you to select standard or optional force levels depending on test requirements.

3. Can you customize the scratch stroke length?

Yes, while the standard stroke range is 0–85 mm, other stroke lengths can be customized to meet specific testing needs.

4. Is the tester suitable for ISO 1518 compliance testing?

Yes, the instrument is designed specifically to meet the requirements of ISO 1518 and related scratch resistance standards.

5. How do you ensure test repeatability?

Repeatability is ensured through stepper motor control, precise load application, adjustable parameters, and consistent scratch needle geometry.

6. What should you do if scratch results appear inconsistent?

You should check needle wear, verify load calibration, confirm sample flatness, and ensure all test parameters are set correctly before retesting.

Leave Message Get Price