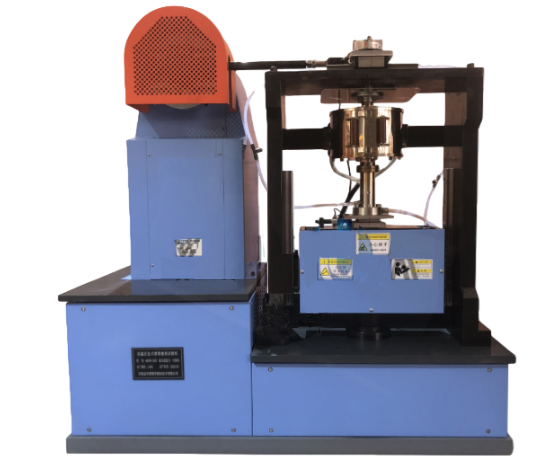

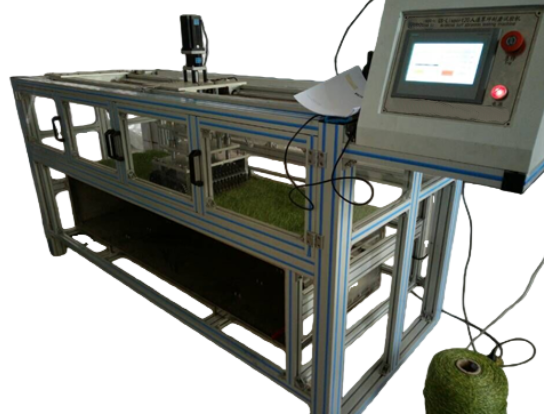

Vertical Universal Friction and Wear Testing Machine

The Vertical Universal Friction and Wear Testing Machine is a high-performance tribological testing instrument designed to simulate friction behaviors under various working conditions. By adjusting parameters such as temperature, load, speed, and friction pair materials, it can perform friction and wear tests for rolling, sliding, and combined rolling-sliding movements. The machine is suitable for evaluating lubricants, metals, coatings, rubber, ceramics, and other materials. It is widely used in tribological research in industries such as petrochemical, machinery, energy, metallurgy, and aerospace.

Application

(1) Research and development in tribology and material sciences.

(2) Friction and wear testing of lubricants, metals, coatings, rubber, ceramics, and other materials.

(3) Simulation of rolling, sliding, and combined rolling-sliding friction types.

(4) Tribological research and new material development in petrochemical, mechanical, energy, metallurgical, and aerospace industries.

Standards

GB 3960-2016: Test Method for Sliding Wear of Plastics

GB/T 8681-2000: Test Method for Metal Tribology

GB/T 2907-2008: Test Method for Rubber Friction and Wear

GB/T 14492-2008: Technical Requirements for Sliding Friction Testing Machines

ISO 7148-1: Metallic Materials – Test Method for Sliding Wear (Pin-on-Disc Method)

ISO 20808: Solid Materials – Test Method for Sliding Wear

ISO 4649: Rubber, Vulcanized or Thermoplastic – Determination of Abrasion Resistance

ASTM G99: Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus

ASTM G133: Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear

ASTM D3702: Standard Test Method for Wear Testing of Elastomeric Materials (Pin-on-Disk)

DIN 50324-1: Tribology – Testing of Friction and Wear – Pin/Disc Method

DIN 50324-2: Tribology – Testing of Friction and Wear – Block/Ring Method

Technical Parameters

| Parameter | Technical Specification |

|---|---|

| Axial Load Range | 10–1000 N |

| Axial Load Relative Error | ±1% |

| Long-Term Load Stability (30 min) | ±1% FS |

| Maximum Friction Torque | 2500 N·mm |

| Friction Torque Relative Error | ±2% |

| Friction Arm Length | 50 mm |

| Main Motor Type | Servo Motor |

| Motor Maximum Torque | 5 N·m |

| Spindle Speed | 1–2000 r/min (stepless adjustable) |

| Spindle Speed Error | ≤100 r/min: ±1 r/min; >100 r/min: ±5 r/min |

| Test Medium | Air, Oil, Water, Slurry, Abrasive |

| Heater Temperature Range | Ambient–260℃ |

| Temperature Control Accuracy | ±2℃ |

| Stop Control Method | Manual/Automatic (time, revolutions, torque, etc.) |

Features

Multi-functional testing: Supports rolling, sliding, and combined rolling-sliding friction modes.

High-precision loading system: Adjustable axial load ensures accurate friction control.

Wide applicability: Suitable for testing lubricants, metals, coatings, rubber, ceramics, and other materials.

High-temperature testing capability: Maximum temperature up to 260℃.

Servo motor drive: Ensures smooth operation for high-speed and high-load friction tests.

Precise control: Supports manual/automatic control of time, revolutions, and friction torque, allowing flexible experiment settings.

Accessories and Consumables

| Item | Description |

|---|---|

| Friction Pair Materials | Metals, non-metals, coatings, etc. |

| Temperature Sensor | For monitoring temperature in high-temperature tests |

| Lubricants | For testing under lubricated conditions |

Testing Principle

The machine simulates friction behaviors under various working conditions. The servo motor drives the spindle to rotate, while different loads, speeds, and friction pair materials are applied. High-precision sensors monitor and adjust the test parameters in real-time, measuring friction torque, coefficient of friction, and wear. Data collected allows accurate evaluation of friction and wear performance.

Operation Instructions

Equipment Installation and Inspection: Ensure stable installation and proper connection to power and test medium.

Sample Preparation: Select suitable friction pair materials and fix samples in place.

Parameter Setup: Set load, speed, test duration, and other parameters via touchscreen.

Start Test: Confirm all settings and initiate the test.

Data Acquisition and Analysis: After testing, analyze data using software, generate reports, and save results.

Experimental Procedure

Select and install friction pair materials and samples.

Set relevant test parameters (load, speed, duration, etc.).

Start the machine to perform the friction test.

Monitor data in real-time and adjust experimental conditions if necessary.

After completion, export results and perform data analysis.

FAQ

1. What is this product?

The Vertical Universal Friction and Wear Testing Machine is a high-performance tribological testing instrument designed to evaluate friction and wear behaviors of various materials and coatings under different working conditions, including rolling, sliding, and combined movements.

2. What is this product used for?

It is used for measuring friction, wear, and related performance parameters of materials such as metals, coatings, rubbers, ceramics, and lubricants under controlled loads, speeds, temperatures, and motion types.

3. Why is this product important?

This machine provides precise, repeatable, and standardized data on friction and wear properties, which is essential for material selection, product development, quality control, and ensuring components meet industry and international standards.

4. What industries is this product suitable for?

It is widely used in petrochemical, machinery, energy, metallurgy, aerospace, automotive, and materials science research laboratories.

5. What types of this product are available?

The Vertical Universal Friction and Wear Testing Machine can be configured for different motion types (rolling, sliding, rolling-sliding), various friction pairs (metal, ceramic, polymer, coating), and optional high-temperature or lubricant testing modules.

Leave Message Get Price