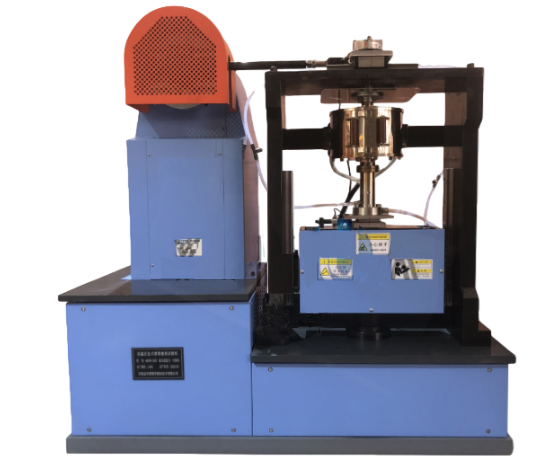

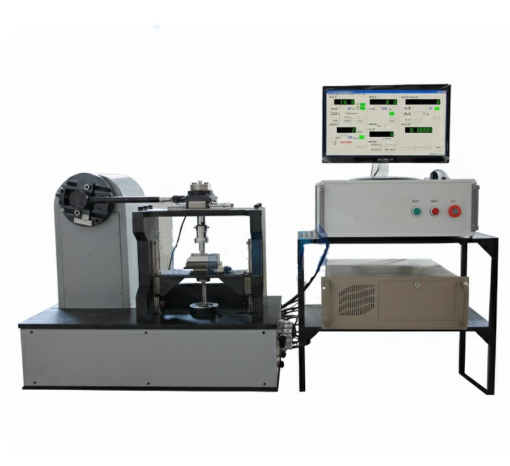

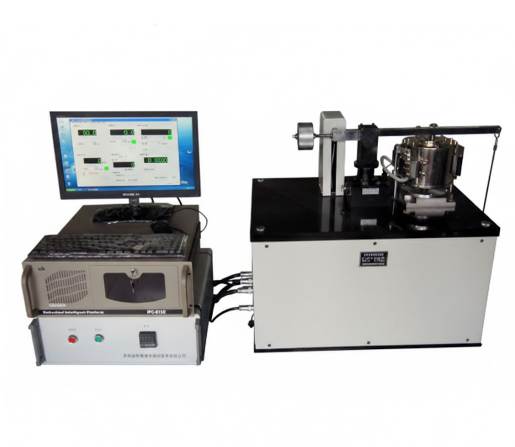

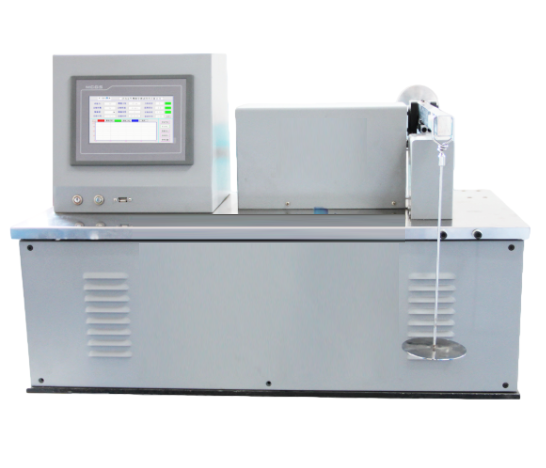

Ring-on-Block Friction and Wear Tester (Type 1)

The Ring-on-Block Friction and Wear Tester (Type 1) is designed to evaluate the wear resistance of metals, non-metallic materials (such as nylon, plastics), and coated surfaces under sliding friction conditions. You can simulate different working environments, including dry and lubricated friction, to study material wear behavior. The device features a color touchscreen for real-time display of test parameters and data curves, facilitating detailed analysis.

Applications

You can use this tester to:

Test the friction and wear performance of metals, non-metals, and coated materials

Simulate dry, wet, or other friction conditions

Support research and development, quality control, and material performance evaluation

Apply in industrial testing, laboratories, and scientific research institutions

Standards

GB 3960-2016 – Test Method for Sliding Friction and Wear of Plastics

ASTM G99 – Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus

ASTM G133 – Standard Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear

ISO 7148-2 – Tribology – Testing of Unlubricated Metal/Metal Sliding Contacts – Part 2: Block-on-Ring and Pin-on-Disc Methods

ISO 20808 – Metallic Materials – Test Method for Sliding Wear

DIN 50324-1 – Tribology – Testing of Friction and Wear – Pin/Disc Method

DIN 50324-2 – Tribology – Testing of Friction and Wear – Block/Ring Method

ASTM D1894 – Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

ASTM D3702 – Standard Test Method for Wear Testing of Plastics with a Pin-on-Disk Apparatus

ISO 4649 – Rubber, Vulcanized or Thermoplastic – Determination of Abrasion Resistance Using a Rotating Cylindrical Drum Device

ASTM F732 – Standard Test Method for Wear Testing of Polymer and Composite Materials

Technical Specifications

| Parameter | Specification |

|---|---|

| Test Force Range | 10 – 1000 N |

| Maximum Friction Torque | 4000 N·mm |

| Spindle Speed Range | 100 – 1000 r/min |

| Test Duration Display & Control | 1 – 99999 s or min |

| Revolutions Display & Control | 0 – 999,999,999 |

| Rated Power | 1.1 kW |

| Dimensions (L × W × H) | Approx. 860 × 400 × 660 mm |

Features

Multi-Functional Testing: Evaluate metals, non-metals, and coated materials under different friction conditions

Adjustable Parameters: Test force, spindle speed, and friction torque are configurable to meet different experimental needs

Real-Time Data Monitoring: Color touchscreen displays and records test data continuously

Data Visualization: Test curves are plotted in real time, clearly showing the wear process

High Reliability: Compact, stable design suitable for laboratory and industrial use

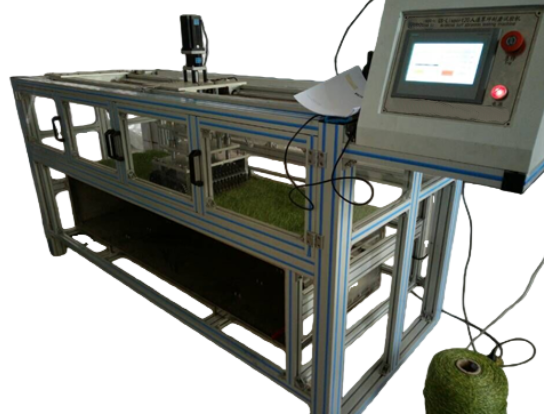

Accessories & Consumables

| Name | Description |

|---|---|

| Friction Pair Materials | Materials for metals, non-metals, and coatings |

| Test Force Sensor | For precise control of applied force |

| Temperature Sensor | Monitors sample temperature during testing |

Testing Principle

The tester simulates different friction conditions (dry or wet friction). Under the set test force and spindle speed, the friction pair slides against the sample. The device collects key data, including friction torque and coefficient of friction, in real time. The touchscreen displays the results, and test curves allow you to analyze material friction and wear performance efficiently.

Operation Instructions

Installation & Inspection: Ensure the tester is installed stably and all electrical and measurement connections are correct

Sample Preparation: Select appropriate friction pair materials and securely mount the samples

Parameter Setup: Use the touchscreen to set test force, spindle speed, and test duration

Start Testing: Confirm all settings and start the test

Data Analysis: After testing, analyze results using the software, save data, and generate reports

Experimental Procedure

Select and install suitable friction pair materials and samples

Set test force, spindle speed, and duration

Start the device and begin friction testing

Monitor friction torque, coefficient of friction, and other parameters during the test

Complete testing, analyze data, save results, and generate reports

FAQ

1.What is this product?

You are using a Ring-on-Block Friction and Wear Tester designed for evaluating sliding wear resistance of metals, non-metals, and coatings.

2.What is this product used for?

You can simulate dry, wet, or other friction conditions to study wear behavior, friction torque, and friction coefficient.

3.Why is this product important?

It provides precise, reproducible data on material friction and wear, which is critical for R&D, quality control, and industrial testing.

4.What industries is this product suitable for?

You can use it in material science, coatings, plastics, metal processing, industrial testing labs, and research institutions.

5.What types of this product are available?

Type 1 supports sliding tests for metals, non-metals, and coated materials under dry or wet conditions, with optional temperature monitoring and real-time data visualization.

Leave Message Get Price