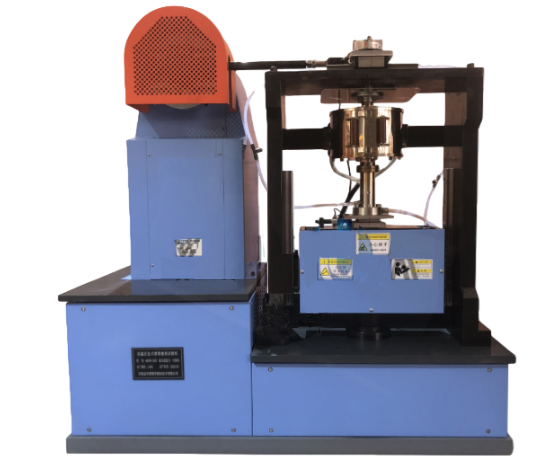

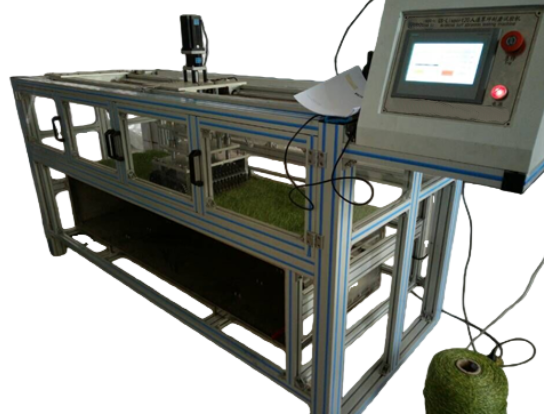

Fully Automatic Falling Sand Abrasion Tester

The Fully Automatic Falling Sand Abrasion Tester is designed to evaluate the wear resistance of anodized aluminum surfaces and organic polymer coatings. The device continuously directs abrasives from a controlled height and stable flow onto the sample surface, using the wear per unit coating thickness as an objective measure of abrasion resistance. This tester is widely used in material wear testing, quality control, and surface treatment industries.

Applications

You can use this tester to assess:

Wear resistance of anodized films on aluminum and aluminum alloys

Abrasion performance of organic polymer coatings and composite coatings

Consistency verification of metal surface treatment processes

Factory inspection and type testing of coated products

Material performance research in third-party laboratories and research institutions

Standards

YS/T 1186-2017: Falling Sand Tester Type B for Anodized Aluminum and Organic Polymer Coatings

Technical Specifications

| Item | Specification |

|---|---|

| Conduit Length | 914 mm |

| Conduit Inner Diameter | 19 mm |

| Hopper Volume | 2.3 L |

| Dimensions (L × W × H) | 900 × 520 × 1900 mm |

| Total Weight | 75 kg |

Features

Uses standardized falling sand abrasion principle with a mature and reliable testing method

Stable and uniform abrasive flow ensures high repeatability

Fully automated operation reduces human error

Strong structural rigidity ensures long-term stability

Suitable for comparative testing of multiple coating systems

Accessories & Consumables

| Name | Description |

|---|---|

| Falling Sand Conduit | Controls abrasive drop height and direction |

| Abrasive Hopper | Stores and evenly releases abrasives |

| Sample Fixture | Secures the test sample |

| Standard Abrasive | Abrasives that meet testing standard requirements |

| Collection Device | Recovers fallen abrasives and wear particles |

Testing Principle

During testing, standardized abrasives fall freely through the conduit under gravity from a specified height, continuously impacting the sample surface. As the test progresses, the coating gradually wears. By measuring the coating thickness or wear per unit area before and after the test, you can evaluate the coating’s abrasion resistance. This method effectively simulates particle-induced wear in real-life use.

Operation Instructions

Check that the conduit, hopper, and fixture are securely installed before testing.

Select and load the specified amount of abrasive according to the standard.

Ensure the sample is firmly fixed, with abrasives impacting the correct test area.

Never open protective devices during testing to avoid abrasive scattering.

Adjust test height, abrasive type, and cycle count according to the relevant standard.

Experimental Procedure

Prepare the sample according to the standard and measure initial coating thickness.

Secure the sample in the fixture.

Add the specified type and amount of abrasive to the hopper.

Adjust the conduit height to ensure vertical abrasive fall.

Start the device and perform the falling sand abrasion test for the specified cycles or time.

After testing, measure the coating thickness or wear amount.

Calculate the abrasion resistance according to standard methods and record the results.

FAQ

1.What is this product?

You are using a Fully Automatic Falling Sand Abrasion Tester, designed to evaluate the wear resistance of anodized aluminum and polymer coatings.

2.What is this product used for?

You can measure coating wear per unit thickness and objectively assess abrasion performance under controlled abrasive impact.

3.Why is this product important?

It provides reliable and repeatable data for quality control, coating comparison, and research, simulating real-life abrasive conditions.

4.What industries is this product suitable for?

You can use it in surface treatment, coatings manufacturing, quality control labs, and materials research institutions.

5.What types of this product are available?

You can select fully automated models with adjustable conduit height, hopper volume, and controlled abrasive flow for various coating systems.

Leave Message Get Price