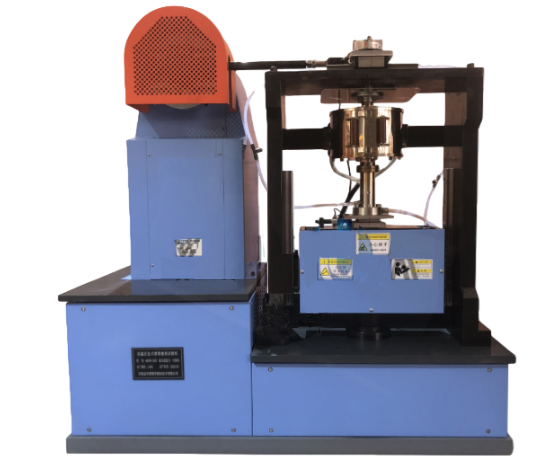

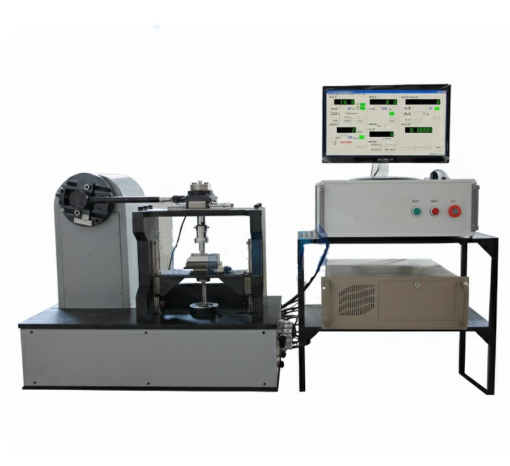

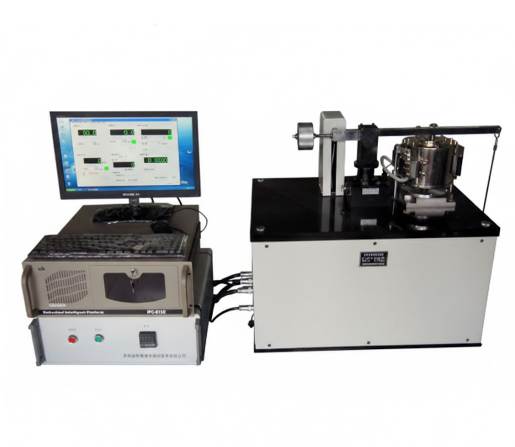

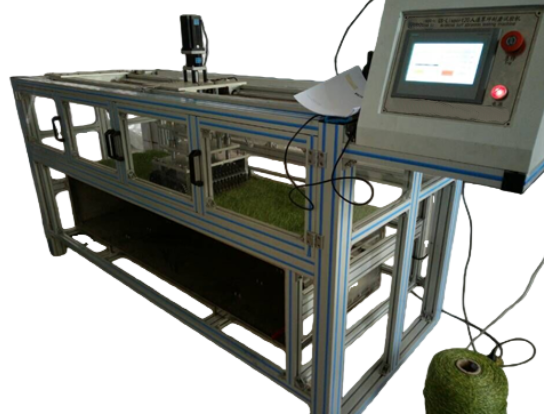

Multi-Functional Tribology Tester

The Multi-Functional Tribology Tester is a high-precision friction and wear testing system designed for materials science, lubricants, oil additives, self-lubricating systems, and the development and quality control of new materials. The device can simulate a variety of real-world conditions, including rotational or linear reciprocating motion, different contact modes, sliding speeds, lubrication conditions, material combinations, temperature, and humidity, providing comprehensive solutions for friction and wear testing.

Applications

You can use this tester for:

Friction and wear testing of metals, ceramics, and polymer materials

Evaluating performance of lubricants and oil additives

Research on wear resistance of self-lubricating systems and coating materials

Laboratory materials development and quality control

High-temperature or liquid environment tribology experiments

Standardized industrial and research tribology studies

Standards

ASTM G99-17: Standard Test Method for Wear Testing of Metal-Metal Sliding Contacts

ASTM G133-05: Standard Test Method for Wear Testing of Rubber and Polymers

DIN 50324-2010: Friction and Wear Testing Standards

Technical Specifications

| Item | Specification |

|---|---|

| Normal Force Range | Up to 60 N |

| Friction Force Range | Up to 20 N (optional 5 N) |

| Friction Force Resolution | 0.06 mN (optional 0.015 mN) |

| Rotational Motion Speed | 0.2–2000 rpm (optional 600 rpm) |

| Rotational Radius | Max 40 mm |

| Maximum Torque | 450 mN·m |

| Linear Reciprocating Stroke | Max 60 mm |

| Linear Reciprocating Speed | Up to 370 mm/s |

| Linear Reciprocating Frequency | 0.01–10 Hz |

| Rotational Reciprocating Speed | 0.2–2000 rpm (optional 600 rpm) |

| Rotational Reciprocating Frequency | 0.01–7 Hz |

| Rotational Reciprocating Angular Amplitude | ±5° to ±150° |

| Deflection Angle Resolution | 0.1° |

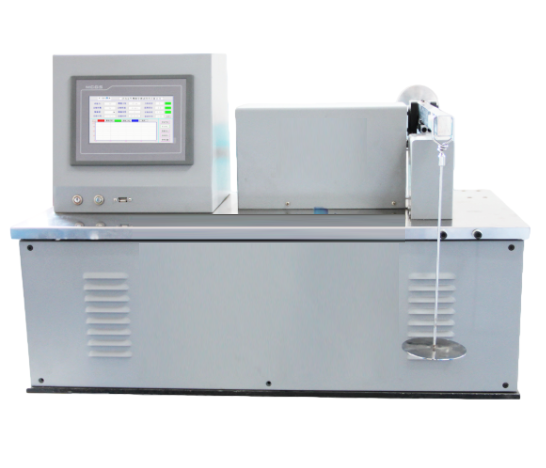

| Environmental Control (Optional) | Temperature: up to 450℃ (dry), 150℃ (liquid); Relative humidity: 15–95%; Vacuum: ≤10⁻⁷ mbar |

| Online Measurement (Optional) | Wear depth: -2 mm to 2 mm |

| Control System | Integrated sensors for real-time monitoring of temperature and humidity, supports “Stress Model” analysis software |

| Software Functions | Standard, incremental, and user-defined parameters; Python programming interface for cyclic and reciprocating motion analysis |

Features

Dual Friction Force Sensors: Minimizes thermal drift and ensures reliable data during long-term testing or environmental changes

Real-Time Environmental Monitoring: Integrated sensors record temperature, humidity, and friction force over time, enabling correlation analysis with friction coefficients

User Calibration: You can calibrate friction force, rotational radius, and motor speed to maintain testing accuracy over time

Multiple Motion Modes: Supports rotational, linear reciprocating, and rotational reciprocating motion to simulate complex friction scenarios

High-Precision Measurement: Friction resolution up to 0.06 mN and angle resolution of 0.1°, meeting high-precision research and industrial requirements

Optional Environmental Control: Supports heating, liquid testing, vacuum, and humidity control for diverse material testing conditions

Advanced Software Analysis: Comes with “Stress Model” software for data visualization, simulating contact stress and strain distribution, and facilitating parameter selection and result evaluation

Accessories & Consumables

| Accessory / Consumable | Description |

|---|---|

| Friction Force Sensors | Dual sensors for high-precision measurement |

| Heating Device | Optional, max 450℃ (dry) and 150℃ (liquid) |

| Vacuum Device | Optional, down to 10⁻⁷ mbar |

| Sample Stage | Compatible with rotational, reciprocating, and rotational-reciprocating motion |

| Tools & Adjustment Components | For calibration and installation |

| Software | Tribology test control software and Stress Model analysis software |

| Data Interface | Supports Python programming environment for data processing |

| Safety Cover | Protects operators from moving parts |

Testing Principle

The Multi-Functional Tribology Tester applies controlled loads via precision loading mechanisms, bringing the friction pair into contact with the sample surface. By performing rotational, linear reciprocating, or rotational-reciprocating motion, the device simulates friction and wear behavior under various conditions. Sensors record friction force, torque, and displacement in real time, and environmental parameters such as temperature and humidity are integrated into the analysis to evaluate material tribological performance and wear patterns.

Operation Instructions

Mount your sample on the adjustable stage, ensuring the contact surface is flat.

Select the desired friction mode (rotational, linear reciprocating, or rotational-reciprocating) and set the normal force and friction pair type.

Configure test speed, frequency, and number of cycles, then start the device.

Monitor friction force and environmental parameters using the integrated sensors.

After the test, save data and evaluate friction and wear results using the analysis software.

Follow safety precautions, avoiding direct contact with moving parts and high-temperature areas.

Experimental Procedure

Sample Preparation: Clean, dry, and secure the sample to ensure a contaminant-free surface.

Equipment Setup: Select the friction pair, applied load, motion mode, and speed parameters.

Environmental Adjustment: Set temperature, humidity, or vacuum conditions as required.

Start Test: Run the device while friction pairs move and friction/wear data are recorded in real time.

End Test: Save all experimental data and analyze friction coefficient curves and wear depth to assess material performance.

Repeat experiments or adjust parameters for comparative testing if needed.

FAQ

1.What is this product?

You are using a Multi-Functional Tribology Tester, a precision system for evaluating friction and wear behavior of various materials under controlled conditions.

2.What is this product used for?

You can measure friction coefficients, wear depth, and material performance under rotational, linear, or combined motion, with optional environmental control.

3.Why is this product important?

It allows you to simulate complex real-world tribological conditions in a controlled environment, providing reliable data for research, development, and quality control.

4.What industries is this product suitable for?

You can use it in materials science, lubrication testing, polymer and coating research, automotive and aerospace R&D, and industrial tribology laboratories.

5.What types of this product are available?

You can configure options for rotational, linear reciprocating, or combined motion, with environmental control (temperature, humidity, vacuum) and advanced software for customized analysis.

Leave Message Get Price