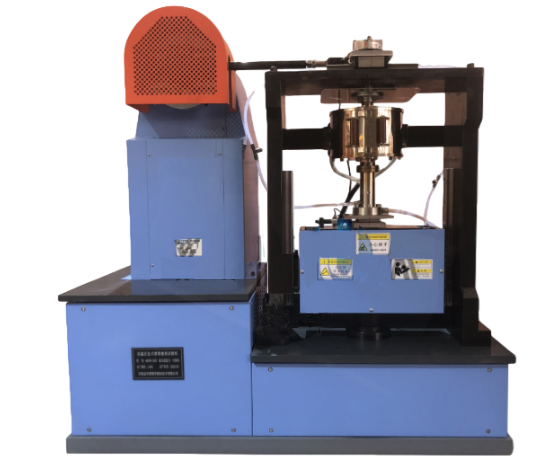

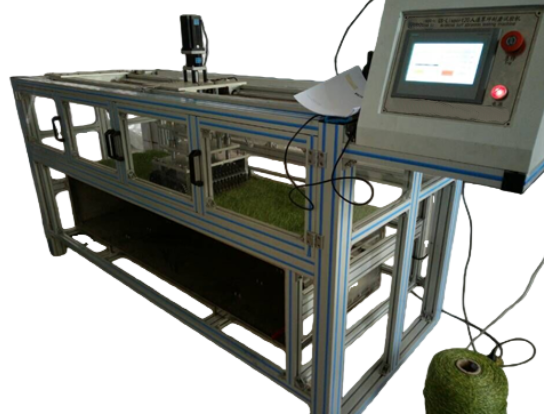

Artificial Turf Abrasion Tester

The Artificial Turf Abrasion Tester is designed to simulate mechanical wear conditions that artificial turf experiences during actual use. By combining controlled rolling and reciprocating motion, the device evaluates the durability and abrasion resistance of turf systems. Featuring a dual-roller structure with independent horizontal and vertical motion systems, it replicates the repeated movements of athletes wearing cleated shoes on turf surfaces, providing reliable testing for quality assessment, product development, and compliance verification.

Applications

You can use this tester to evaluate the abrasion resistance of:

Artificial turf systems for football, rugby, hockey, and other sports fields

Filled and unfilled artificial turf

Various pile structures, including monofilament, fibrillated, and mesh grass

Different synthetic turf fibers such as polyethylene and polypropylene

Type testing, factory inspection, and third-party evaluation of finished turf products

Quality control and acceptance of sports field construction projects

Research on turf wear mechanisms in laboratories and testing institutes

Standards

GB/T 20394-2013: Sports Artificial Turf (China)

BS EN 13672:2004: Determination of Abrasion Resistance of Artificial Surfaces for Sports Areas

BS EN 15306: Determination of Simulated Wear Performance of Artificial Sports Surfaces

FIFA Quality Concept for Football Turf (2006)

FIFA 09: Mechanical Durability and Abrasion Testing Requirements for Artificial Turf

Technical Specifications

| Item | Specification |

|---|---|

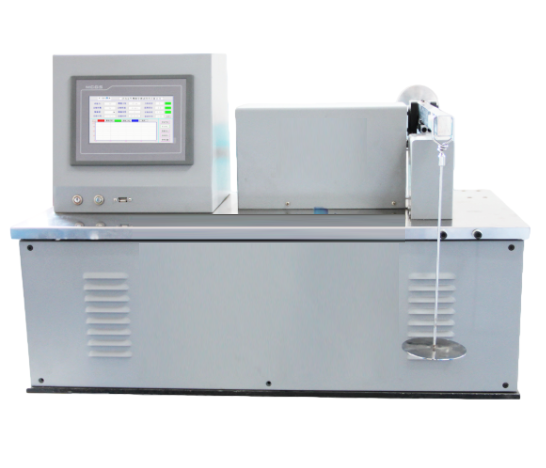

| Control System | PLC + Touchscreen operation |

| Display | 7-inch full-color LCD touchscreen |

| Operation Mode | Manual / Automatic |

| Data Output | RS232 interface, supports print output |

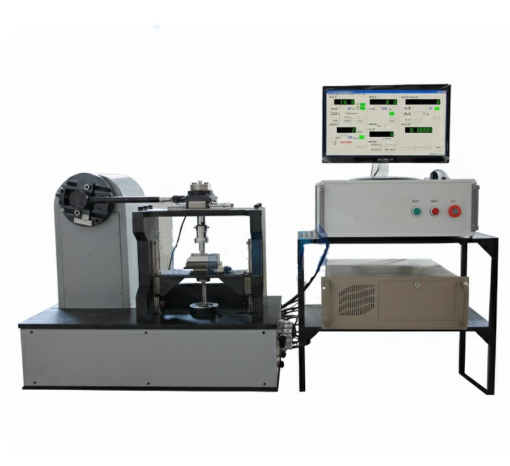

| Drive System | Servo motor + Stepper motor + Variable frequency AC motor |

| Main Drive Motor | 1 unit |

| Height Adjustment Motor | 1 unit (Stepper motor) |

| Horizontal Movement Motor | 1 unit (Variable frequency AC motor) |

| Test Accuracy | Dimension D ±0.2 mm; Position P ±2 mm |

| Roller Type | Dual-roller structure |

| Roller Size | 2 × 0.3 m |

| Roller Diameter | 118 ± 5 mm |

| Single Roller Weight | 28,500 ± 500 g (including roller, cleats, and shaft) |

| Abrasion Roller | Cylindrical roller with attached cleats |

| Test Cycles | Adjustable within standard range |

| Test Speed | Adjustable within standard range |

| Power Supply | AC 220 V / 50 Hz |

| Rated Power | 3 kW |

Features

Dual independent horizontal and vertical motion systems realistically simulate multi-directional wear on artificial turf

Dual-roller structure with cleated abrasion rollers meets FIFA and EN standards for simulated wear

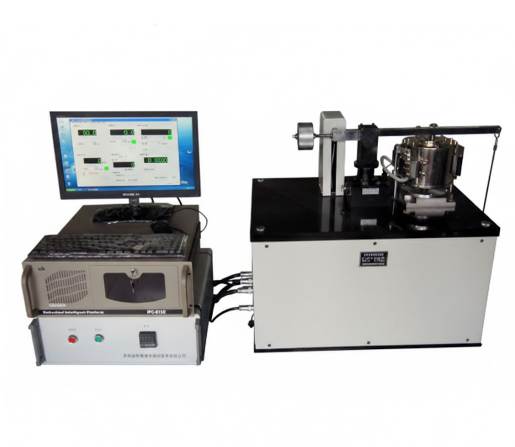

Test parameters can be flexibly set on the control interface, accommodating different cycle counts and speeds required by various standards

Drawer-style sample design allows easy replacement, inspection of wear, and topping up of infill material

Trench-shaped collection system recovers excess infill to maintain a clean testing environment

Fully transparent protective enclosure allows real-time observation while ensuring safety and noise reduction

Intelligent control system supports continuous cyclic testing with pause and inspection capabilities

Accessories & Consumables

| Category | Item | Description |

|---|---|---|

| Standard | Dual-Roller Assembly | Includes cylindrical abrasion rollers with cleats |

| Standard | Sample Fixture | For positioning and securing turf samples |

| Standard | Drawer-Style Sample Tray | Facilitates sample replacement and infill addition |

| Standard | Transparent Protective Cover | Aluminum frame + acrylic panels |

| Standard | Control System | PLC controller + touchscreen |

| Consumable | Cleat Assemblies | Replace periodically according to wear |

| Consumable | Roller Bearings | Maintenance or replacement after prolonged use |

| Consumable | Infill Material | Added according to test standard requirements |

Testing Principle

The device applies repeated rolling and reciprocating motion to artificial turf samples under controlled load, speed, and motion paths. The cleated roller surface simulates athletes’ movements with cleated shoes, including walking, turning, and sprinting.

A combination of random-force abrasion and lateral-motion abrasion prevents predictable wear paths, realistically reflecting the turf’s long-term durability. After the specified wear cycles, the structural changes and mechanical properties of the turf are evaluated.

Operation Instructions

Confirm that sample dimensions, infill height, and compaction meet standard requirements.

Ensure all safety doors are closed during testing; opening a door will automatically stop the device.

Select the correct test program according to the standard, adjusting cycles, speed, and motion mode.

You may pause the device during testing to inspect the sample, but ensure it is fully stopped before opening safety doors.

Regularly check cleat wear to avoid inconsistencies in test results.

Experimental Procedure

Cut and install turf samples according to relevant standards, adjusting height and infill condition.

Set test parameters, including wear method, number of cycles, and running speed.

Start the device to perform random-force or lateral-motion abrasion testing.

The device automatically cycles until the specified wear period is completed.

Remove the sample after testing.

Conduct follow-up performance tests on the worn sample, such as shock absorption, vertical deformation, ball rebound, and rotational resistance.

FAQ

1.What is this product?

You are using an Artificial Turf Abrasion Tester, designed to simulate wear and evaluate durability of artificial turf systems.

2.What is this product used for?

You can assess the abrasion resistance, durability, and mechanical performance of various turf systems under simulated athletic use.

3.Why is this product important?

It allows you to replicate real-world wear conditions in a controlled environment, providing reliable data for quality evaluation, product development, and standard compliance.

4.What industries is this product suitable for?

You can use it in sports facility construction, artificial turf manufacturing, testing laboratories, and research institutions.

5.What types of this product are available?

You can select models with dual independent motion systems and cleated rollers, configurable for different turf types, pile structures, and testing standards.

Leave Message Get Price