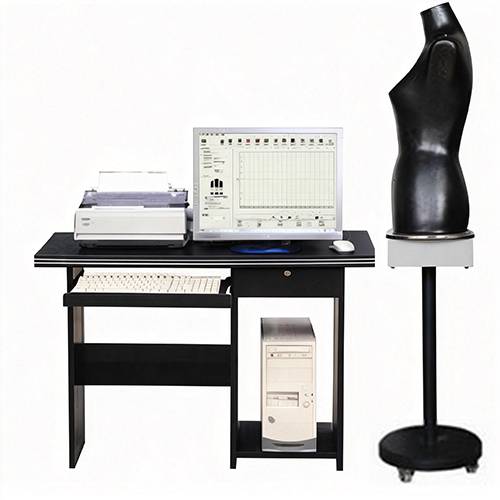

G138 Yarn Evenness Tester

The G138 Yarn Evenness Tester is designed for precise evaluation of linear density uniformity and unevenness characteristics of yarns and slivers. Using a capacitive measurement principle combined with advanced digital signal processing and precision speed control, it provides comprehensive statistical analysis and graphical representation of yarn quality. The system supports automatic adjustment, data storage, and report printing, making it suitable for both laboratory and industrial quality control applications.

Application

The G138 Yarn Evenness Tester is suitable for evaluating yarns and slivers in the textile industry. Typical applications include:

Single and plied yarns made from cotton, wool, flax, and chemical staple fibers

Blended yarns with complex fiber compositions

Linear density uniformity assessment of slivers and rovings

Yarn quality control during production and post-processing

Research and development of spinning, twisting, and blending processes

Detection of yarn defects such as thin places, thick places, and neps

Standards

The instrument complies with international and national standards for yarn evenness testing, including:

(1) ASTM D1425 — Standard Test Method for Single Yarn Evenness

(2) ISO 2060 — Textile Fibres — Determination of Linear Density of Textile Fibres

(3) ISO 1889 — Yarn Evenness Measurement Using Capacitance Method

(4) GB/T 1290 — Cotton Yarn Evenness Test Method

(5) ISO 7211 — Test Methods for Yarn Properties

Parameters

| Item | Technical Specification |

|---|---|

| Measuring Range | 4 tex – 80 ktex; sliver, roving, yarn |

| Test Speed | 25, 50, 100, 200, 400 m/min |

| Measuring Channels | 5 |

| Test Data | Coefficient of Variation (CV%), Unevenness (U%), Average Factor (AF) |

| CVm% Levels | 1 m, 5 m, 10 m, 50 m, 100 m |

| Thin Places | −30%, −40%, −50%, −60% |

| Thick Places | +35%, +50%, +70%, +100% |

| Neps | +140%, +200%, +280%, +400% |

| Drift Rate (DR%) | Two levels: (1 m, +5%), (1 m, −5%) |

| Additional Statistics | Mean per 1 km (Mean/1 km), between-package coefficient of variation (CVb) |

| Confidence Statistics | Confidence interval Q95%, Maximum (Max), Minimum (Min) |

| Displayed Graphs | Unevenness curve, spectrogram, three-dimensional spectrogram, mass distribution diagram |

| Drift Rate–Threshold Curve | Lengths: 1 m, 10 m, 20 m, 50 m, 100 m; threshold: 0 ±50% |

| CV%–Length Curve | Cut length: 0–100 m |

| Intelligent Analysis | Built-in USTER Statistics 2013 edition; automatic quality grade determination |

| Expert Analysis System | Intelligent localization of mechanical faults |

| Spectral Amplitude | Quantitative evaluation of mechanical wave severity, precise CV% representation |

| Sample Identification | Yarn packages can be numbered by workshop, machine, and spindle for fast fault localization |

Features

Capacitive high-frequency measurement ensures accurate linear density detection

Advanced digital signal processing with Windows-based software interface

Automatic zero and mean value adjustment, automatic range selection

Comprehensive display of statistical data, unevenness curves, spectrograms, 3D graphs, and distribution diagrams

Intelligent expert system for mechanical fault localization and analysis

Built-in USTER 2013 standards for yarn quality assessment

Sample tracking by machine, spindle, and workshop for precise process control

Data storage and report printing for quality traceability

Accessories

(1) Main tester unit with integrated computer interface

(2) Capacitive measurement sensor module

(3) Pneumatic and mechanical yarn clamps

(4) Power cable and connection accessories

(5) User manual and software documentation

(6) Printer for test reports

Test Procedures

(1) Prepare and condition yarn or sliver samples according to test standards

(2) Mount the sample on the tester using the clamps

(3) Select measurement range, test speed, and statistical parameters

(4) Start the test and monitor the display of CV%, U%, AF, and graphical curves

(5) Observe spectrograms, drift rate, and variation-length curves for detailed analysis

(6) Save or print the results for record-keeping and quality evaluation

Maintenance Information

Keep the capacitive sensors clean and dust-free

Periodically calibrate the measuring channels

Inspect yarn clamps and pneumatic components for wear

Ensure the software is updated to the latest version

Store the instrument in a controlled laboratory environment

FAQ

1. What is this product?

The G138 is a yarn evenness tester that evaluates linear density uniformity and defect distribution in yarns and slivers.

2. What is this product used for?

It measures CV%, unevenness, thin/thick places, neps, and other parameters, and provides graphical and statistical analysis for quality control and research.

3. Why is this product important?

Evenness and defect detection directly affect yarn quality, fabric performance, and downstream processing efficiency.

4. What industries is this product suitable for?

It is suitable for spinning mills, textile manufacturing, R&D laboratories, and quality inspection facilities.

5. What types of this product are available?

The G138 series supports single and plied yarn testing, with customizable speed, measurement channels, and software options for different yarn types.

Leave Message Get Price