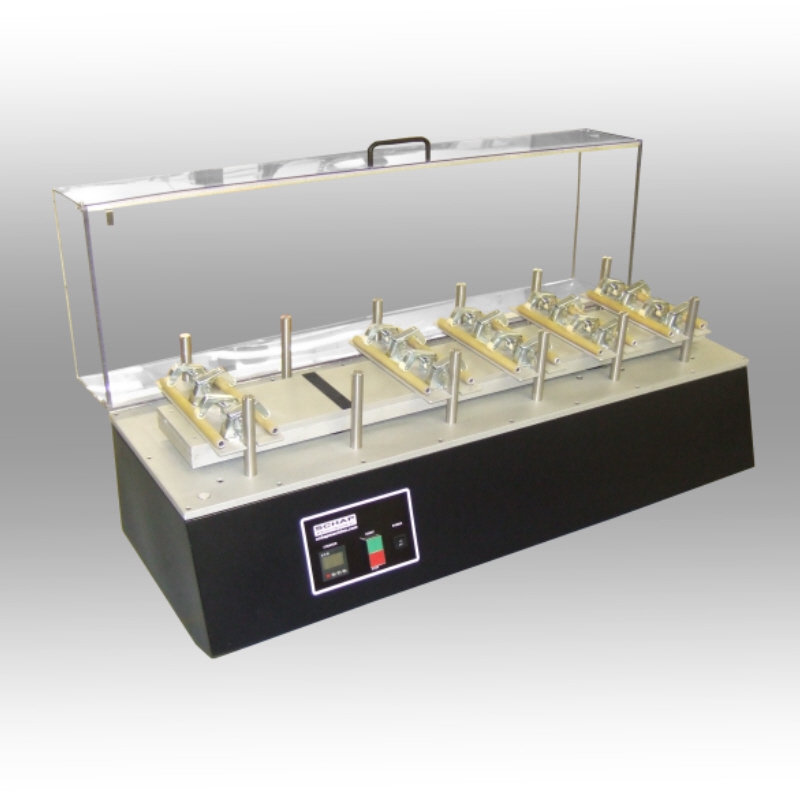

Schap Brush-Type Pilling and Fuzzing Tester

The Schap Brush-Type Pilling and Fuzzing Tester is a six-station testing instrument designed to evaluate the abrasion resistance and pilling performance of fabrics and leather. Samples are subjected to controlled friction cycles using standardized abrasives such as nylon brushes, sponges, or hook-and-loop materials. Pilling and surface wear are assessed against industry standards or laboratory-developed reference standards, providing reliable documentation of fabric performance.

Application

(1) Woven fabrics: cotton, polyester, wool, blended fabrics, printed and dyed textiles.

(2) Knitted fabrics: jerseys, interlocks, rib knits, fleece, and sportswear fabrics.

(3) Leather and synthetic leather: automotive interiors, upholstery, footwear, bags, and jackets.

(4) Specialized textiles: automotive seat covers, protective clothing, home textiles (curtains, bedding, blankets), and carpets.

(5) Anti-pilling and surface treatment evaluation: fabrics treated with anti-pilling finishes, softeners, or coatings.

(6) Comparative quality control: finished garments, fabric rolls, and leather panels for industrial and consumer applications.

Standards

(1) Ford BN 125-01 — Automotive Fabric Pilling Test Standard

(2) ASTM D3511 — Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Brush Method

(3) Ford BN 108-03 — Fabric Testing Equipment Standard

(4) Ford BN 108-14 — Leather Testing Equipment Standard

(5) GM 9652 — Automotive Fabric Pilling Test Standard

Features

Six independent test stations for simultaneous evaluation of multiple samples.

Mechanical components made of corrosion-resistant aluminum and stainless steel.

Durable powder-coated and anodized surfaces.

Precision ball and needle bearings for smooth operation.

Programmable automatic stop with upward counting controller.

Adjustable slow and standard test speed controls.

Ventilated safety cover to protect operators from moving parts.

High-quality brushless motor.

Supply voltage must be specified at purchase.

One-year manufacturer warranty.

Parameters

| Parameter | Specification |

|---|---|

| Number of Test Stations | 6 |

| Sample Clamps | Adjustable stainless steel clamps (6 per set) |

| Standard Testing Accessories | Ford Leather Equipment (BN 108-14), Ford Fabric Equipment (BN 108-03), ASTM Fabric Equipment (ASTM D3511) |

| Material | Corrosion-resistant aluminum and stainless steel |

| Surface Treatment | Powder-coated and anodized finish |

| Motor | High-quality brushless motor |

| Control | Programmable automatic stop, adjustable test speed |

| Safety | Ventilated protective cover |

| Dimensions (Main Unit) | 48" × 19" × 18" |

| Weight | 240 lbs / 109 kg |

| Shipping Dimensions | 24" × 50" × 30" |

| Optional Accessories | Adjustable support frame for tool heads and weights, dimensions 43" × 18" × 37.5" |

FAQ

(1) What is this product?

A six-station brush-type pilling and fuzzing tester for evaluating the surface durability and pilling performance of textiles and leather.

(2) What is it used for?

To assess fabric and leather resistance to pilling and abrasion under controlled laboratory conditions.

(3) Why is it important?

Ensures consistent quality of fabrics and leather used in apparel, home textiles, and automotive interiors.

Provides objective, reproducible data to compare materials and validate anti-pilling treatments.

(4) What problems does it solve for users?

Prevents product quality issues by accurately simulating wear and recording pilling behavior.

Supports compliance with multiple international standards.

(5) What types of fabrics can be tested?

Woven, knitted, leather, and synthetic leather materials used in apparel, home textiles, and automotive applications.

(6) How is the test performed?

Samples are mounted on adjustable clamps and subjected to friction cycles with nylon brushes, sponges, or hook-and-loop materials.

After a set number of cycles, the sample surface is compared against reference standards for pilling and fuzz formation.

Leave Message Get Price