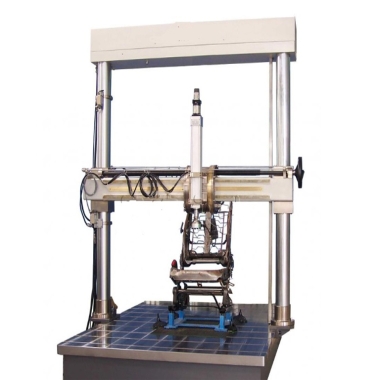

Computer controlled foam universal testing machine

The Computer Controlled Foam Universal Testing Machine is designed for mechanical property testing of soft polymer foam materials. The system adopts servo motor drive with double precision ball screw transmission and high-precision force measurement technology. It is capable of performing tensile, compression, tearing, hardness, and compression permanent deformation tests on polyurethane foam materials, providing accurate measurement of force, displacement, deformation, stress, and strain parameters.

Application

(1) Tensile strength and elongation at break testing of soft polyurethane foam.

(2) Tear strength determination of soft foam polymer materials.

(3) Compression hardness testing of polyurethane foam.

(4) Compression permanent deformation (compression set) testing of foam materials.

(5) Stress–strain behavior analysis of foam polymers.

(6) Quality control and material research in foam manufacturing laboratories.

(7) Performance evaluation of foam materials in research institutes and inspection organizations.

Standards

(1) GB/T 6344-2018 — Determination of Tensile Strength and Elongation at Break of Flexible Cellular Polymer Materials

(2) GB/T 6669-2008 — Determination of Compression Set of Flexible Cellular Polymer Materials

(3) GB/T 10807 — Test Method for Compression Hardness of Flexible Cellular Polymer Materials

(4) GB/T 10808 — Test Method for Tear Properties of Flexible Cellular Polymer Materials

(5) ISO 1798 — Flexible Cellular Polymeric Materials — Determination of Tensile Strength and Elongation at Break

(6) ISO 1856 — Flexible Cellular Polymeric Materials — Compression Set

(7) ISO 3386 — Flexible Cellular Polymeric Materials — Determination of Stress-Strain Characteristics in Compression

(8) ASTM D3574 — Standard Test Methods for Flexible Cellular Materials — Slab, Bonded, and Molded Urethane Foams

(9) HY-0580 — Enterprise Standard

Features

(1) Servo motor drive with double precision ball screw for stable and accurate loading.

(2) High-precision force sensor with full-range linear response.

(3) Support for tensile, compression, tear, and deformation tests.

(4) Multiple curve display modes for tensile and compression testing.

(5) Local curve amplification and regional data analysis functions.

(6) Automatic storage of test conditions, results, curves, and sample data.

(7) Automatic stop at specimen break.

(8) Multiple report export formats including Excel, Word, and PDF.

(9) Automatic overload, over-current, over-voltage, under-voltage, and over-temperature protection.

(10) Constant force and constant deformation control modes.

(11) Manual and automatic zero-setting for load, displacement, and deformation.

(12) Manual control box with LCD display for beam positioning.

Parameters

| Item | Specification |

|---|---|

| Testing machine grade | 0.5 |

| Maximum test force | 1 kN – 20 kN |

| Effective force measurement range | 0.4% – 100% FS |

| Load measurement accuracy | ±0.5% |

| Force resolution | 1 / 300000 |

| Displacement measurement range | 0 – 999 mm |

| Displacement resolution | 0.001 mm |

| Displacement accuracy | ±0.5% |

| Beam deformation measurement accuracy | ±0.5% |

| Beam deformation measurement range | 600 mm |

| High-precision sensor accuracy | ±0.5% |

| Effective test width | 900 mm |

| Test speed range | 0.05 – 500 mm/min (stepless) |

| Speed accuracy | ±0.5% |

| Maximum effective beam travel | 1200 mm |

| Uniform force/deformation rate control range | 0.01% – 10% FS/s |

| Uniform force/deformation rate control error | ±0.5% |

| Constant force/deformation control range | 0.5% – 100% FS |

| Constant force/deformation control error | <10% FS: ±1% set value; ≥10% FS: ±0.1% set value |

| Power supply | AC 220 V, 0.5 kW |

Accessories

(1) Tensile grips for foam materials.

(2) Compression platens.

(3) Tear test fixtures.

(4) High-precision force sensor.

(5) Computer control and analysis software.

(6) Manual LCD control box.

Test Procedures

(1) Select the appropriate test method according to the applicable standard.

(2) Install the corresponding fixture and force sensor.

(3) Mount the foam specimen correctly and ensure alignment.

(4) Set test parameters such as speed, force, or deformation mode.

(5) Zero load, displacement, and deformation channels.

(6) Start the test and monitor real-time curves.

(7) Automatically stop at specimen break or preset condition.

(8) Save test data and generate test reports.

Leave Message Get Price