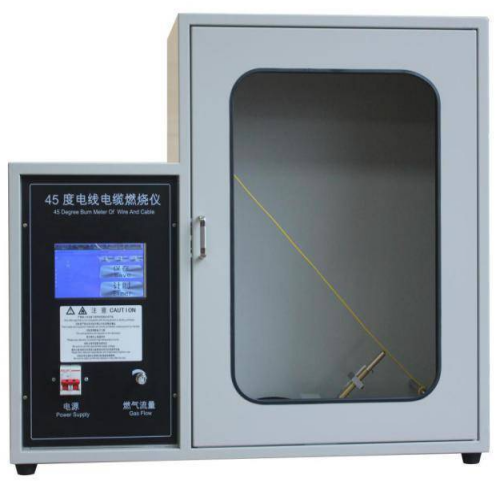

Flame Retardant Tester for Synthetic Sports Track Surface Materials

The Flame Retardant Tester for Synthetic Sports Track Surface Materials is designed to evaluate the flame resistance of horizontal synthetic track surfaces under controlled flame exposure. It is developed according to GB/T 14833-2011, Appendix D, and provides precise and repeatable assessment of surface burning characteristics for quality control, R&D, and regulatory compliance of synthetic track materials.

Application

This tester is widely used for:

(1) Evaluating flame resistance of synthetic running track layers in schools, sports facilities, and stadiums.

(2) Quality control of PU, rubber, or composite sports surface materials before installation.

(3) Research and development of flame-retardant coatings and additives for synthetic track materials.

(4) Testing surface layers of athletic tracks, gym flooring, and playground synthetic mats.

(5) Regulatory compliance testing according to national and international flame resistance standards.

Tested products include: PU track layers, EPDM/rubber track surfaces, multi-layer composite track sheets, and other horizontal synthetic surfaces.

Compliance Standards

(1) GB/T 14833-2011 — Synthetic material track surfaces — Appendix D: Flame retardant testing method (China national standard)

(2) ISO 11925-2 — Reaction to fire tests — Ignitability of building products exposed to direct flame

(3) EN 13501-1 — Fire classification of construction products and building elements

(4) Relevant ASTM, UL, or IEC standards for flame resistance testing of polymer and composite materials

Technical Parameters

| Parameter | Specification |

|---|---|

| External Dimensions | 650 × 500 × 840 mm (L × W × H) |

| Built-in Fume Hood | Yes, with 80 mm exhaust duct |

| Hood & Chamber Material | Brushed stainless steel |

| Ignition Source | 25 mm diameter thin cotton disc |

| Combustion Medium | 96% industrial alcohol |

| Power Supply | AC 220 V, 30 W |

| Sample Requirements | 100 × 100 mm specimens from different locations; 5 specimens per test |

| Preconditioning | Samples placed in testing environment for at least 48 h |

| Test Procedure | Igniting alcohol-soaked cotton discs on sample; measure burn mark diameter after flame extinguishes |

| Pass Criteria | Burn mark diameter ≤50 mm for all 5 specimens = Class 1 flame retardant |

| Measurement Precision | 1 mm |

| Safety Measures | Ventilated hood, fume extraction, stainless steel chamber |

Package List

Main Tester Unit ×1

User Manual ×1

10 mL Graduated Cylinder ×1

150 mm Steel Ruler ×1

Pine Board ×1

FAQ

(1) What materials can be tested?

Synthetic sports track surfaces such as PU, rubber, EPDM, or composite track layers.

(2) What is the flame source?

A 25 mm diameter cotton disc soaked with 2.5 mL of 96% industrial alcohol.

(3) How is the result evaluated?

Measure the diameter of the burn mark after flame extinguishes; ≤50 mm for all 5 specimens = Class 1 flame retardant.

(4) What standards does it comply with?

GB/T 14833-2011 (Appendix D), ISO 11925-2, EN 13501-1, and relevant international flame retardancy testing standards.

(5) What is the required preconditioning?

Samples must be placed in the testing environment for at least 48 hours before testing.

Leave Message Get Price