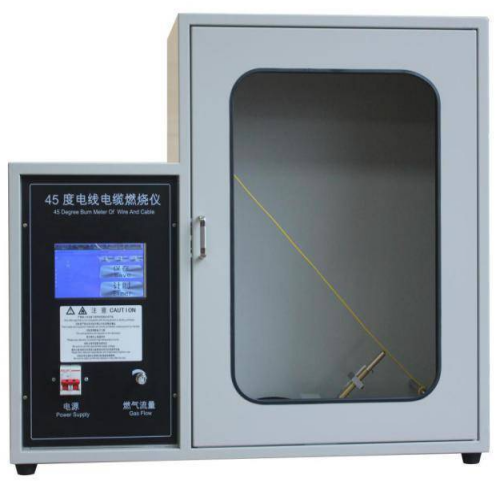

Thermal Load Testing Apparatus for Insulation Rock Wool

The Thermal Load Testing Apparatus for Insulation Rock Wool is designed for evaluating the thermal load performance and heat-load shrinkage temperature of rock wool and mineral wool insulation products. It provides precise heating control, accurate measurement of thermal deformation, and reliable assessment of material performance under high temperatures. The device is widely used in research, quality control, and production testing of insulation materials.

Application

This apparatus is widely used for:

(1) Testing thermal load and heat-induced shrinkage of insulation rock wool and mineral wool boards, blankets, or panels.

(2) Evaluating fire resistance and heat stability of insulation materials used in construction and industrial applications.

(3) Research and development in building materials for energy-efficient and fire-safe insulation.

(4) Quality control in rock wool manufacturing plants for batch verification of thermal performance.

(5) Educational and testing laboratories for materials science and civil engineering studies.

(6) Safety and regulatory compliance testing of insulation materials according to national and international standards.

Tested products include rock wool boards, batts, slabs, blankets, and composite insulation panels.

Compliance Standards

(1) GB/T 11835-2007 — Thermal load testing of insulation rock wool, mineral wool, and related products (China national standard)

(2) GB/T 5480-2017 — Methods for testing mineral wool and its products (China national standard)

(3) ISO 1716-2002 — Reaction to fire tests for building products — Determination of calorific value

(4) Relevant international building and insulation material standards for thermal stability and fire performance

Technical Parameters

| Parameter | Specification |

|---|---|

| Display & Control | 7-inch full-color touchscreen, multi-point programmable heating |

| Screen Size | Effective display: 15.5 × 8.6 cm |

| Resolution | 800 × 480 pixels |

| Communication Interfaces | RS232, 3.3 V CMOS or TTL, serial port |

| Storage Capacity | 1 GB |

| Control Architecture | M3 + FPGA; M3 for instruction parsing, FPGA for TFT display |

| Instrument Weight | 50 kg |

| Ambient Conditions | Room temperature to 40 °C; relative humidity ≤75% |

| Working Voltage | AC 220 V ±10%, 50 Hz |

| Total Power | 2.5 kW |

| Heating Power | 1000 W |

| Temperature Measurement Range | Room temperature to 900 °C |

| Heating Rate | 0–400 °C: 5 °C/min; 400–800 °C: 3 °C/min |

| Sample Fixture | Stainless steel, corrosion-resistant |

| Thermal Source | Hot plate |

| Test Sample Pressure | 490 Pa |

| Test Tube Diameter | 48 mm ±1 mm |

| Display Driver | Pure hardware FPGA, zero startup time, energy-saving mode |

FAQ

(1) What is the purpose of this apparatus?

It measures the thermal load resistance and heat-induced shrinkage temperature of rock wool and mineral wool insulation materials.

(2) What types of products can be tested?

Rock wool boards, slabs, batts, blankets, and composite insulation panels.

(3) How is the device controlled?

Through a 7-inch full-color touchscreen with multi-point programmable heating; M3 + FPGA architecture ensures fast response and energy-efficient operation.

(4) What standards does it comply with?

GB/T 11835-2007, GB/T 5480-2017, ISO 1716-2002, and related international standards for thermal stability and fire performance of insulation materials.

(5) What is the heating range and rate?

Room temperature up to 900 °C, with programmable rates of 5 °C/min (0–400 °C) and 3 °C/min (400–800 °C).

Leave Message Get Price