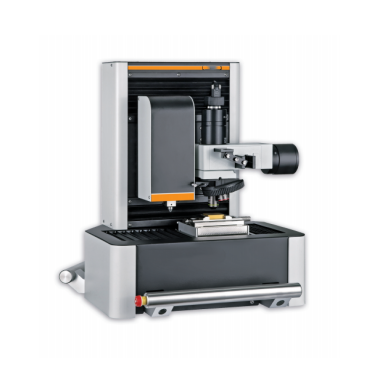

Thermal Conductivity Tester

The Intelligent Flat Plate Thermal Conductivity Tester is a state-of-the-art laboratory instrument designed to measure the thermal conductivity of a wide range of materials, including plastics, rubber, glass, fiberboard, polystyrene boards, extruded boards, foamed concrete, hollow glass, wood panels, and various insulation materials. It also supports measurements of granular materials, powders, and soft materials. By integrating a water bath constant temperature system with full computer control, the instrument ensures fast, accurate, and highly automated thermal conductivity measurements.

The system utilizes a Visual Basic 6.0 interface for intuitive operation. Test data is saved in Excel format for easy processing, and real-time curves can be printed or stored, allowing full documentation of each experiment. The automated system enables precise control, data acquisition, calculation, display, and printing of thermal conductivity results with minimal noise and high efficiency.

Application

(1) Thermal conductivity measurement for building insulation materials and heat-resistant boards.

(2) Evaluation of plastics, rubbers, foams, and composite materials in research and development.

(3) Quality control and compliance testing in manufacturing plants for thermal insulation products.

(4) Laboratory testing of granular, soft, and particulate materials for heat transfer properties.

(5) Research applications in universities and scientific institutes requiring precise thermal measurements.

(6) Assessment of energy efficiency and heat retention performance for construction and industrial materials.

Compliance Standards

The Intelligent Flat Plate Thermal Conductivity Tester complies with the following national standards:

GB/T 10294-2008 – Steady-state thermal resistance and related properties of insulating materials.

GB/T 3399-1982 – Plastics thermal conductivity test using protected flat plate method.

GB/T 10801.1-2002 – Polystyrene foam for insulation.

GB/T 10801.2-2002 – Extruded polystyrene foam for insulation.

GB/T 3139-2005 – Thermal conductivity of fiber-reinforced plastics.

GB/T 17794-2008 – Flexible foam rubber and plastic insulation products.

Product Features

Powder-coated outer casing for corrosion resistance, mechanical strength, and aesthetic durability.

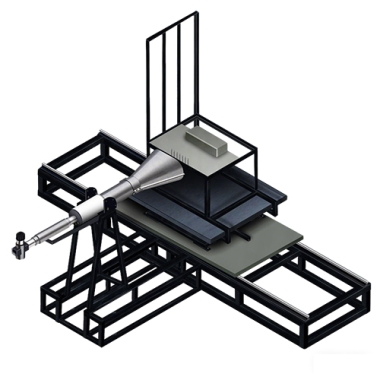

Single-specimen design with one-sided heating, eliminating the need for dual specimens and cooling units.

Mobile design with caster wheels for flexibility and easy relocation.

Horizontal specimen placement with automated cold plate lifting for simple setup.

Durable water circulation system with pressure- and corrosion-resistant silicone tubing.

High safety with electrical and water circuits fully isolated.

Excellent temperature stability with protective boards minimizing heat loss.

Online dual calibration for temperature and system error ensures accuracy and efficiency.

Short test duration (typically 120–150 minutes).

Wide measurement range: 0.002–1.000 W/(m·K).

Supports special material testing with optional fixtures (granular, soft, soil, or particulate materials).

Thickness and pressure displayed in real-time upon specimen placement.

Advanced control system with Omron PLC, integrated temperature modules, and Schneider solid-state relays for high reliability.

Fully automated test procedure with easy-to-follow operation steps.

RS-232 data interface ensures stable, interference-resistant data acquisition.

User-friendly computer interface with automatic and manual control modes, real-time curve display, report generation, data storage, and export functionality.

Software interface in Chinese with Internet application capabilities and Windows compatibility.

Recommended computer configuration: Intel Core 2 Duo E3500 2.7GHz, 2GB RAM, 500GB HDD, DVD drive, Windows OS, USB 2.0 ports, pre-installed software, and necessary accessories.

Technical Parameters

| Parameter | Specification |

|---|---|

| Standard Specimen Size | 600 × 600 × 5–100 mm |

| Specimen Flatness | 0.1 mm |

| Thermal Conductivity Range | 0.002–1.000 W/(m·K) |

| Measurement Accuracy | ±3% |

| Repeatability | ±1% |

| Temperature Range | -5℃ to 100℃ |

| Temperature Resolution | 0.01℃ |

| Laboratory Temperature | 23 ± 2℃ |

| Laboratory Humidity | 40–60% RH |

| Power Supply | 380V, 2.5 kW |

| Specimen Thickness Range | 5–100 mm |

| Clamping Pressure | ≤2.5 kPa |

| Number of Specimens | 1 |

FAQ

Q1: What types of materials can be tested?

A1: The tester supports rigid boards, plastics, rubbers, foams, granular materials, powders, soft materials, and composite insulation products.

Q2: How is thermal conductivity measured?

A2: The device uses a steady-state flat plate method with precise temperature control and real-time computer monitoring, ensuring highly accurate and repeatable results.

Q3: Can the system handle soft or irregular samples?

A3: Yes, with optional fixtures, granular, soft, or soil-like materials can be tested with the same high accuracy.

Q4: How is data recorded and analyzed?

A4: Test results are saved in Excel format, with real-time curve plotting, automatic calculation, and full report generation for easy data analysis and documentation.

Q5: What makes this tester different from conventional thermal conductivity meters?

A5: Full automation, advanced temperature stability, online dual calibration, wide measurement range, flexible sample handling, and computer-integrated data acquisition and control set it apart.

Leave Message Get Price