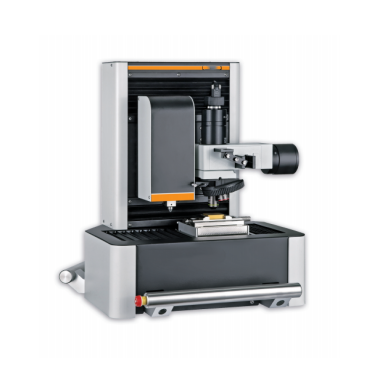

Needle Flame Tester IEC 60695

The Needle Flame Tester is a state-of-the-art instrument designed for evaluating the ignition hazard of electrical and electronic products under small flame conditions. It precisely simulates the effect of minor accidental flames caused by faults or malfunctions, helping manufacturers and testing laboratories determine material fire risks.

Equipped with a full-color 7-inch touchscreen and motorized sample holder movement in both horizontal and vertical directions, the device enables fully automated flame positioning and retraction, eliminating manual handling errors common in traditional testers. The system integrates control, monitoring, and data acquisition for a streamlined testing workflow.

Application

The Needle Flame Tester is widely used in:

(1) Electrical and electronic product manufacturers for flame hazard assessment.

(2) Fire safety laboratories conducting product certification and compliance testing.

(3) Research institutions developing flame-retardant plastics, polymers, and composite materials.

(4) Quality control departments in household appliances and industrial electronics.

(5) Regulatory and certification agencies for UL, IEC, and GB standard compliance verification.

(6) Component-level fire risk testing for wires, insulating materials, and small parts.

This instrument is ideal for both research and routine safety testing of electrical devices, polymers, coatings, and composite materials.

Compliance Standards

Design Standards:

GB5169.5-2008 – Fire hazard testing of electrical and electronic products, Part 5: Needle flame test method, apparatus and verification

GB4706.1-2005 – Household and similar electrical appliances – General safety requirements

Reference Standards:

IEC60695-11-5 – Fire hazard testing, needle flame test

GB/T5169.5-2008 – Electrical and electronic products, needle flame test

GB4706.1-2005 – General safety requirements for household appliances

These standards ensure the tester meets both national and international fire safety testing requirements.

Technical Parameters

| Parameter | Specification |

|---|---|

| Flame type | Needle-shaped burner |

| Burner inner diameter | Φ0.5 mm ± 0.1 mm |

| Burner outer diameter | ≤ Φ0.9 mm |

| Burner length | ≥ 35 mm |

| Flame angle | Adjustable 0–45° |

| Flame height | 12 mm ± 1 mm (with height gauge) |

| Ignition source | 95% Butane (or bottled LPG, user-supplied) |

| Flame exposure time | 0–999.9 s ± 0.1 s (adjustable, automatic burner movement) |

| After-flame time | 0–999.9 s ± 0.1 s, automatic recording, manual pause possible |

| Temperature testing range | 0–1000°C |

| Flame temperature | 100°C ±2°C to 700°C ±3°C in 23.5 s ±1 s |

| Thermocouple | Φ0.5 mm K-type, NiCr/NiAl, electrically insulated |

| Heat transfer block | Φ4.0 × 6.0 mm copper |

| Sample holder movement | Automated horizontal and vertical adjustment via touchscreen |

| Control system | PLC + 7-inch full-color touchscreen |

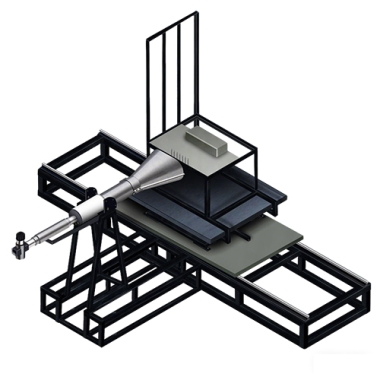

| Burn area volume | >0.5 m³ (approx. 900×590×1050 mm) |

| Background | Black, illumination ≤20 Lux |

| Safety features | Optional gas alarm system, independent fume extraction |

| Dimensions | 1160×600×1310 mm (customizable) |

Key Features

Fully automated flame exposure, retraction, and timing for minimal human error.

Integrated touchscreen controls all test functions: ignition, timing, gas supply, lighting, and exhaust.

Programmable PLC system records flame duration and automatically generates test results.

Adjustable burner angle, flame height, and sample positioning ensure accurate simulation of real-world fire hazards.

Safety-focused design with independent extraction and optional gas alarm system.

FAQ

Q1. What materials can be tested?

The tester is suitable for insulating materials, plastics, polymers, coatings, and components used in electrical and household appliances.

Q2. How is the needle flame applied?

The flame automatically moves to the sample position upon start, remains for the programmed duration, and retracts without manual handling.

Q3. Can the burner angle and flame height be adjusted?

Yes, the flame angle is adjustable from 0–45° and the height can be measured and calibrated using the built-in height gauge.

Q4. What type of gas is required?

95% butane is recommended, though bottled LPG can also be used (gas supply and connection fittings are user-supplied).

Q5. How is data recorded and analyzed?

The PLC system automatically logs flame exposure and after-flame times, generates results, and stores them for review.

Leave Message Get Price