Smoke Density Tester ASTM D2843

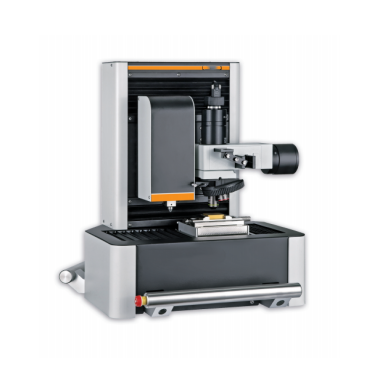

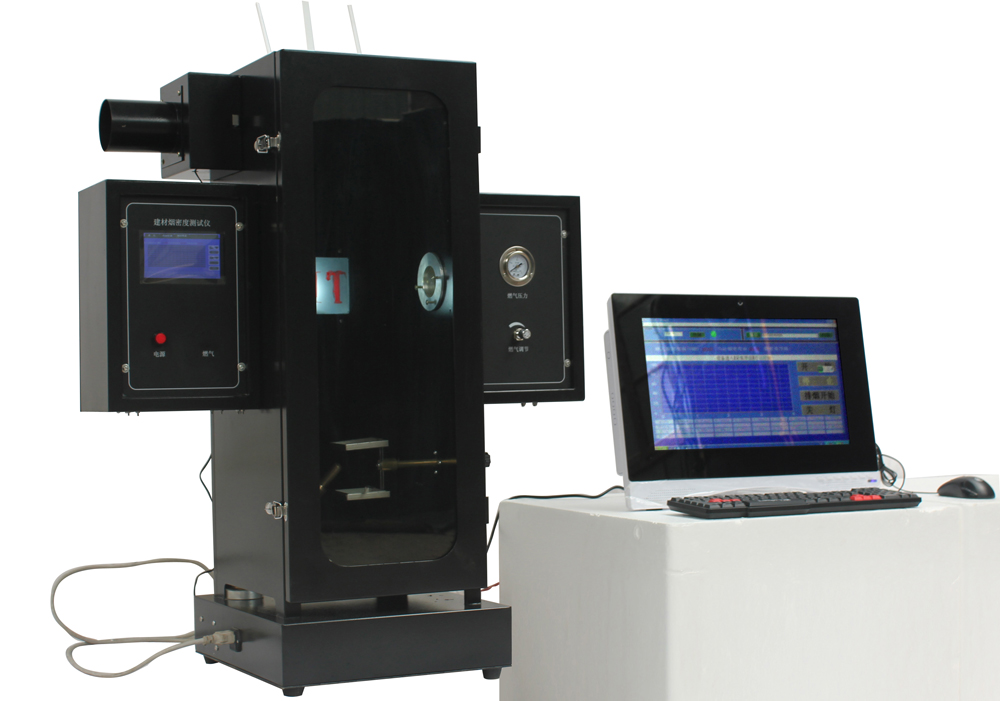

The Building Material Smoke Density Tester is a precision instrument designed to measure the smoke density produced by burning or decomposition of building materials. The device evaluates both the maximum smoke density (MSD) and the smoke density rating (SDR), providing essential data for fire safety analysis, regulatory compliance, and material development.

Engineered with dual control functionality, the tester supports both touchscreen and computer-based operation, allowing multiple workstations to operate simultaneously over a local network. It is suitable for a wide range of building materials, including panels, insulation boards, coatings, and other construction-related materials.

Application

The Building Material Smoke Density Tester is widely used in:

(1) Construction and building material manufacturers to evaluate smoke generation during combustion.

(2) Fire safety laboratories for testing compliance with national and international standards.

(3) Research institutions developing low-smoke or fire-retardant materials.

(4) Insulation, polymer, and composite material testing for smoke emission characteristics.

(5) Quality control departments ensuring material safety before commercial release.

(6) Certification and regulatory bodies verifying compliance with GB/T and ASTM smoke density standards.

This tester is ideal for evaluating materials in office, residential, and industrial construction applications, including walls, floors, ceilings, panels, and coatings.

Compliance Standards

The tester is designed according to:

Design Standard:

GB/T 8627-2007 – Test Method for Smoke Density of Building Materials during Combustion or Decomposition

Compliance Standards:

GB/T 8627-2007

ASTM D2843 – Standard Test Method for Smoke Density in Fire Conditions

These standards ensure that the smoke density testing meets national and international fire safety certification requirements.

Technical Parameters

| Item | Specification |

|---|---|

| Smoke density measurement range | 0–100% (continuous, automatic calculation) |

| Smoke density accuracy | ±3% |

| Maximum smoke density (MSD) | 0–100% |

| Smoke density rating (SDR) | 0–100% |

| Calibration | Three standard optical filters; error ≤3% |

| Main burner working pressure | 276 KPa (adjustable) |

| Auxiliary burner (optional) | Adjustable for enhanced testing conditions |

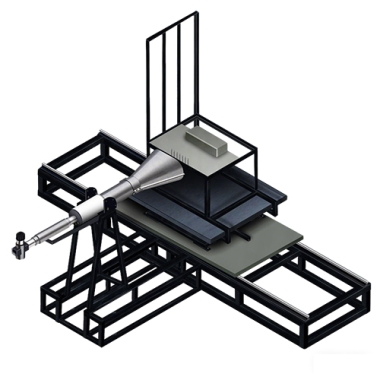

| Burner type | Bunsen burner, length 260 mm, nozzle 0.13 mm, 45° angle to smoke chamber |

| Photometric system | 15 W lamp, 6 V working voltage |

| Receiver | Silicon photocell, 0–100% light transmission |

| Exhaust system | High-power fan, external discharge |

| Control interface | Touchscreen: 5-inch, 800×480 resolution, FPGA + M3 architecture, 1 GB storage |

| Data acquisition | Real-time curve display, automatic recording and calculation |

| Automation | Automatic ignition, timing, exhaust, and linear calibration of light flux |

| Gas supply | 95% propane or equivalent gas (user-supplied) |

| Smoke chamber dimensions | 740 × 500 × 900 mm (L×W×H) |

| Power supply | 220 V ±10%, 50 Hz, 100 W |

| Working environment | Temperature: 0–40°C; Relative humidity ≤85%; no strong air flow |

FAQ

Q1. What materials can be tested with this smoke density tester?

It is suitable for all types of building materials, including insulation boards, wall panels, coatings, polymers, and composite construction materials.

Q2. How is smoke density measured?

The tester uses an optical system with a calibrated light source and photocell receiver to detect transmitted light, automatically calculating the maximum smoke density (MSD) and smoke density rating (SDR).

Q3. Can the tester be operated remotely?

Yes. The instrument supports dual control: direct touchscreen operation or computer-based control via a local network, enabling multiple workstations to access the device simultaneously.

Q4. What safety features are included?

Automatic exhaust, ignition, and burner control ensure safe operation. The device should be placed inside a fume hood, and a 15-minute cooling period is recommended after 90-minute tests.

Q5. Does the tester meet international standards?

Yes. It is compliant with GB/T 8627-2007 and ASTM D2843, suitable for both domestic and international fire safety testing and certification.

Q6. What are the calibration requirements?

The tester comes with three standard optical filters for calibration, ensuring a measurement error of no more than ±3%.

Leave Message Get Price