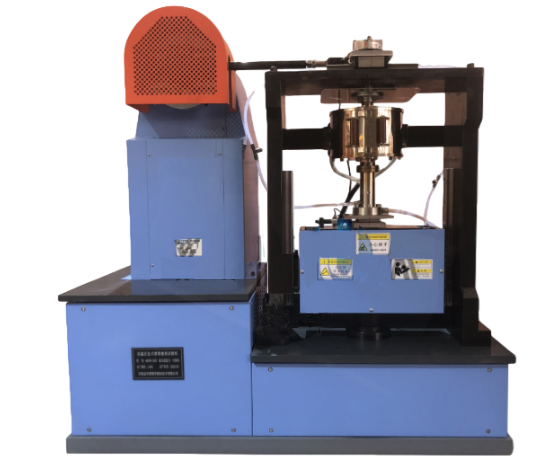

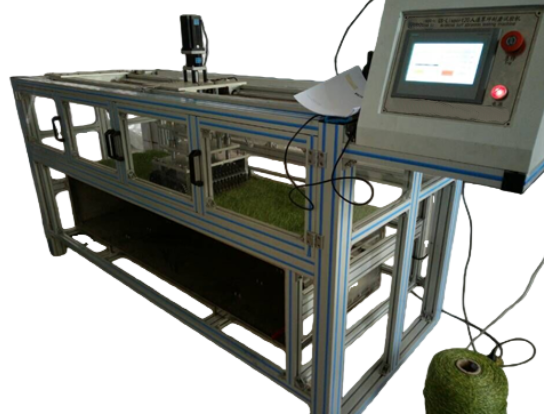

Circular Locus Pilling Tester

The Circular Locus Pilling Tester evaluates the pilling performance of textiles, including wool, chemical fiber, cotton, blended fabrics, knitted and woven materials. The instrument simulates abrasion by rubbing the fabric against nylon brushes or abrasive surfaces under controlled conditions to assess product quality and process performance.

Applications

Testing pilling and fuzzing resistance of knitted, woven, and blended fabrics

Evaluating material quality and manufacturing effects

Performance assessment for wool, chemical fiber, cotton, and military textiles

Standards Compliant

| Standard | Scope |

|---|---|

| GB/T 4802.1 | Determination of pilling properties of textiles – Circular trajectory method |

| JIG | Bell-type gas flow standard device verification procedures |

| DIN | Testing of textiles – Wear test of flat fabrics – Roll to mill method |

Key Features

Smooth Mechanical Operation: Scientific design ensures quiet, stable, and long-term continuous operation

Standard Nylon Brush: Uniform rigidity controls consistent pilling effect

Ergonomic Design: Smooth, aesthetically finished surface for user comfort and durability

Adjustable Parameters: Customizable pressure, cycle count, and brush contact to accommodate different fabric types

Durable Construction: Built for repeated testing without mechanical fatigue or failure

Test Reference

| Sample Type | Pressure (cN) | Fluff Cycles | Pilling Cycles |

|---|---|---|---|

| Synthetic fiber knitted fabric | 590 | 150 | 150 |

| Chemical fiber woven fabric | 590 | 50 | 50 |

| Military service (combed blended) | 490 | 30 | 50 |

| Combed wool fabric | 780 | 0 | 600 |

| Coarse wool fabric | 490 | 0 | 50 |

Technical Parameters

| Parameter | Specification |

|---|---|

| Grinding head contact with plane | ≤ 0.2 mm |

| Parallelism of grinding head and plane | ≤ 0.3 mm |

| Relative movement trajectory | 40 ± 1 mm |

| Nylon brush surface flush height difference | < 0.5 mm |

| Grinding plane reciprocating speed | 60 ± 1 cycles/min |

| Grinding head weight | 490 cN ± 1% |

| Heavy hammer weight | 290 cN ± 1% |

| Hammer weight | 100 cN ± 1% |

| Number of cycles | 1–9,999 |

Why Choose Us

Professional textile testing instrument manufacturer

Fully compliant with GB/T, JIG, and DIN standards

Accurate and repeatable results for R&D, quality control, and production monitoring

Ergonomic, durable design for long-term laboratory or industrial use

FAQ

1. What types of fabrics can be tested?

Wool, chemical fibers, cotton, blended, knitted, and woven fabrics.

2. How is pilling simulated?

By rubbing fabric against standard nylon brushes or abrasive surfaces under controlled pressure and cycles.

3. Can the testing parameters be adjusted?

Yes, pressure, cycle count, and brush contact can be customized.

4. What is the maximum number of cycles?

Up to 9,999 cycles per test.

5. Is it suitable for continuous long-term operation?

Yes, the scientific mechanical design ensures smooth, noise-free, and fatigue-resistant operation.

Leave Message Get Price