Gelbo Flex Tester System

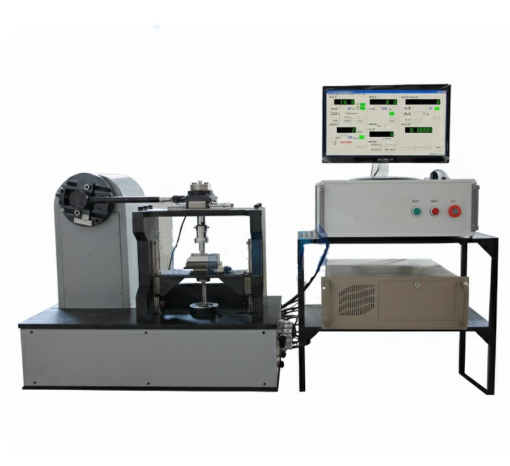

The Gelbo Flex Tester System is a microprocessor-controlled instrument designed to evaluate the lint generation and particle release from surgical drapes, gowns, and cleanroom textiles under repetitive flexing. Fully programmable for ASTM F392, the system is versatile, accurate, and user-friendly, requiring minimal training.

With an integrated laser particle counter, it monitors and classifies airborne particles during torsion and compression cycles, providing reliable data for clinical, surgical, and cleanroom applications.

Applications

Testing disposable and reusable surgical drapes, gowns, and cleanroom garments

Evaluating lint generation for patients, clinical staff, and equipment

Quality control for medical textiles and cleanroom fabrics

R&D in nonwoven and surgical textile manufacturing

Testing Standards

| Standard | Scope |

|---|---|

| YY/T 5056.6 | Surgical drapes, gowns, and clean air suits – Dry lint test methods |

| ISO 9073-10 | Textiles – Nonwovens – Lint and particle generation in dry state |

| EN 13795-2:2004 | Surgical drapes, gowns, and clean air suits – Test methods |

Test Principle

Samples in the torsion chamber undergo repetitive twisting and compression cycles. During torsion, air is withdrawn from the chamber and particles are counted and classified by a laser dust particle counter, simulating real-world usage conditions for medical and cleanroom textiles.

Key Features

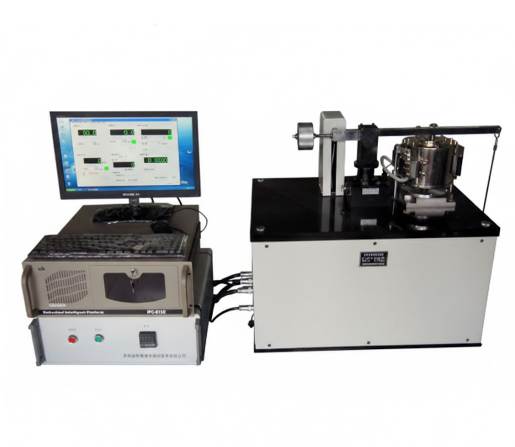

Microprocessor Control: Programmable methods for ASTM F392 and custom protocols

Integrated Particle Counting: Laser counter measures particle size (0.3–25 μm) and concentration

High Precision Torsion: 180° twist angle with 120 mm stroke at 60 cycles per minute

Data Logging: Stores up to 3,000 test records with adjustable cycles (1–9,999)

Electrostatic-Resistant Chamber: Transparent acrylic chamber with controlled airflow

Versatile Sample Fixtures: 82.8 mm fixture diameter for standard textile samples

Cleanroom Compatible: Level 5 (ISO 14644-1 Class 100) testing environment

Technical Parameters

| Parameter | Specification |

|---|---|

| Twist Speed | 60 cycles/min |

| Twist Angle / Stroke | 180° / 120 mm |

| Sample Fixture Diameter | 82.8 mm |

| Particle Size Range | 0.3 – 25 μm |

| Particle Counter Flow Rate | 28.3 L/min ±5% |

| Data Storage | 3,000 test records |

| Timer / Cycle Count | 1–9,999 cycles |

| Test Environment | Level 5 cleanroom |

| Chamber Material | Electrostatic-resistant acrylic |

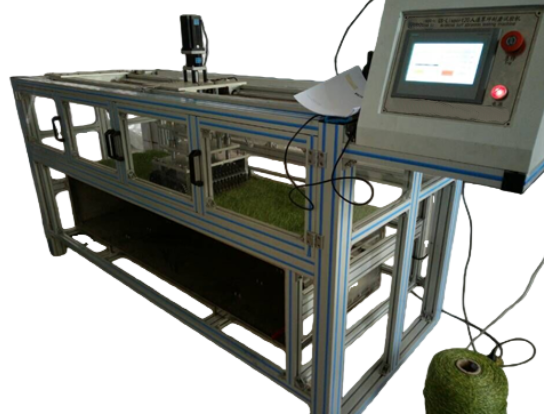

Structure Overview

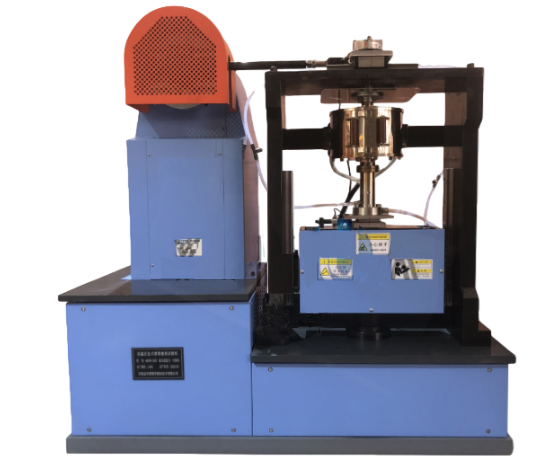

Dry Lint Generator

Torsion device: applies torsion, compression, and recovery forces

Electrostatic-resistant torsion chamber with acrylic body

Air sampler: positioned to collect representative sample air

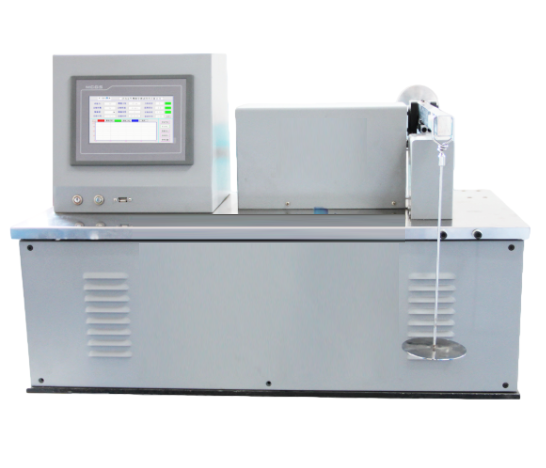

Laser Dust Particle Counter

Counts and classifies airborne particles generated during the test

Provides quantitative evaluation of lint and particle release

Why Choose Us

Professional medical textile testing instrument manufacturer

Compliant with ASTM, ISO, YY/T, and EN standards

Accurate, automated, and easy to operate

Ideal for quality control, R&D, and regulatory compliance

Full support: installation, training, and maintenance

FAQ

1. What types of textiles can be tested?

Disposable and reusable surgical drapes, gowns, and cleanroom garments.

2. How is particle data measured?

A laser dust particle counter classifies and counts particles from 0.3–25 μm in real time.

3. Can the tester simulate real usage?

Yes, torsion and compression cycles replicate normal wear and handling.

4. How many cycles can be set per test?

Programmable from 1 to 9,999 cycles with automatic stop.

5. Is the tester suitable for cleanroom use?

Yes, it is compatible with Level 5 cleanroom (ISO Class 100) conditions.

Leave Message Get Price