Pull off adhesion tester

Adhesion is the ability for a coating such as paints and varnishes to adhere to a substrate termed as ‘substrate adhesion’ or the ability for a coating to adhere to multiple coats in the system which is termed ‘inter-coat adhesion’. For coatings to perform satisfactorily, they must adhere to the substrate on which they are applied including metal, concrete, wood, and more.

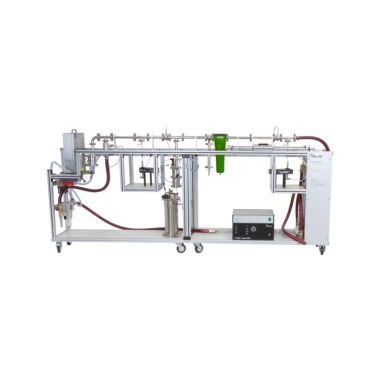

The Adhesion Tester is easy to operate and fully portable, and provides a numerical value for adhesion. Applications for the Adhesion Test include paint or plasma spray on bridge decking, coatings on steel, aluminium, concrete etc.

What is pull-off adhesion testing:

In accordance with ASTM D4541/D7234. ISO 4624. and others, adhesion testers evaluate the adhesion (pull-off strength) of a coating by determining the greatest tensile pull-off force that it can withstand before detaching. Breaking points, demonstrated by fractured surfaces, occur along the weakest plane within the system consisting of the dolly (loading fixture, pull stub), glue, coating layer(s), and the substrate.

Why is it necessary to test adhesion:

The goal of adhesion testing is to produce a coating failure. Coating adhesion is an indicator of how well the surface was prepared and how well the coating has bonded to the surface and/or additional coating layers. Testing adhesion offers a quantifiable method of determining if a paint or coating system is fit-for-purpose and ready to meet the quality demands of job specifications.

Testing standards:

ASTM C1583/D4541/D7234/D7522.

ISO 4624/16276-1.

EN 1542/12004-2.

AS/NZS 1580.408.5 and others

AS/NZS 1580.408.5 and others

Product Parameters:

Select from four Stand-offs - 20 mm, 50 mm, 50x50 mm Tile and 50 mm C1583

Environmentally sealed enclosure—weatherproof, dustproof and shockproof—meets or exceeds IP65

Inexpensive, single-use dollies eliminate cleaning for re-use and can be kept as a permanent record

Self-aligning aluminum dolly enables accurate measurements on smooth or uneven surfaces

10. 14. 20 or 50 mm dollies maximize capability and measurement resolution across a wide range of bond strengths

Calibrated and certified to ± 1% accuracy using a NIST traceable load cell

Certificate of Calibration showing traceability to NIST included (Long Form)

Test Method:

An adhesion test dolly is bonded to the coating using an adhesive. The adhesion tester houses a spring arrangement which applies a lift force to the dolly as the tension is increased.

When the coating is pulled off the surface, an indicator on the scale shows the numerical value of adhesion expressed in terms of the force per unit area required to remove the dolly.

Inspection of the dolly face is required to determine the failure mode.

To increase sensitivity at low values or for uneven surfaces, a 40mm (1.52") dolly is available. When using the 40mm (1.52") dolly, divide the scale reading by 4.

Leave Message Get Price