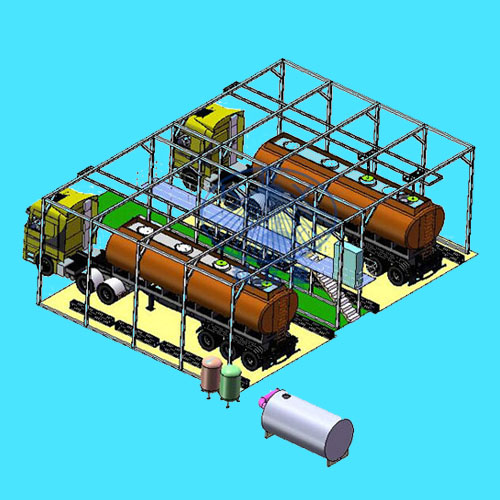

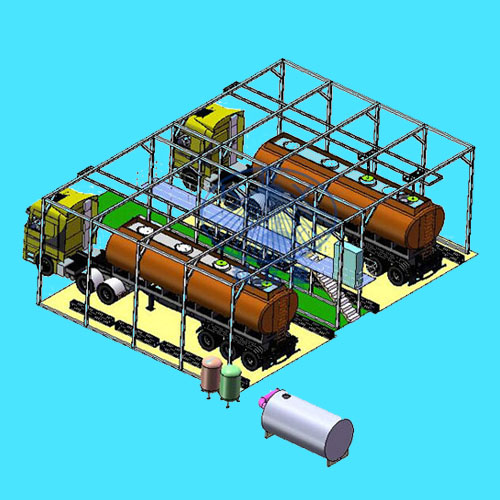

Automatic cleaning system for highway transportation tank car

The RTSC series automatic cleaning system is suitable for cleaning tank car that transport dangerous chemical products; tank trucks are loaded with chemical media such as BDO, RNMP, animal oil, tallow, vegetable oil, alcohols, ethers, organic solvents, acids, alkalis, etc. This system is suitable for a series of operations such as automatic degreasing cleaning, hot water cleaning, normal temperature water cleaning, drying, and testing of 20-48m tank trucks.

Working principle:

This equipment is used for internal cleaning of tank trucks. The equipment working mode is fully automatic program control. According to the cleaning environment and tank conditions, the camera and light source are assisted; the manhole position is automatically determined, and the cleaning head automatically moves in the direction to clean each compartment one by one; after the cleaning is completed, the hot air system of the hot air blower is used for drying; the camera transmits the cleaning video inside the tank, and the manual terminal observes and inspects the tank. No one goes down the tank throughout the process, and a series of automated processes such as residual oil discharge, tank steaming, cleaning, sewage recovery, drying, and testing of the entire oil tank are completed. The cleaning operation is carried out according to the assembly line, and the tank body is cleaned synchronously in sequence (including extraction of residual liquid, steaming tank, cleaning, drying, testing, etc.), which improves the cleaning quality and cleaning speed.

Product features and advantages of tank car cleaning equipment:

1. The safety protection measures during mechanical cleaning are perfect to eliminate the safety threats caused by entering the tank;

2. The mechanical cleaning system is fully enclosed, with a high degree of mechanization and less manpower, avoiding long-term work in harsh environments;

3. The mechanical cleaning time is short, the tank mouth time is less, and the tank stop time is reduced;

4. The circulating water is separated from oil and water, and it can be discharged only when it reaches the standard value. The cleaning effect is good and the crude oil recovery rate is high;

5. Mechanical cleaning does not discharge oil pollution outside the oil tank. The recovered crude oil is transferred to the critical tank after filtration. The generated sewage is treated by the oil-water separation device, the residual oil is recovered, and the sewage and dirt are treated to the discharge standard value before being discharged.

Note:QINSUN is very in place for textile testing and quality control,we have our own textile testing lab. Our textile testing equipment and testing methods are in the leading position in the industry. We have passed the textile testing certification and iso textile testing standards issued by a number of testing,We can provide textile testing equipment pdf manual. Sufficient inventory, big discounts, limited time promotion, Order now!

Leave Message Get Price